Multi-chamber container with device for discharge of a substance

a technology of a container and a discharge device, which is applied in the field of containers, can solve the problems of contamination of the contents of the container, unappetizing, inedible or toxic, etc., and achieve the effects of reducing the number of production steps, high degree of accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

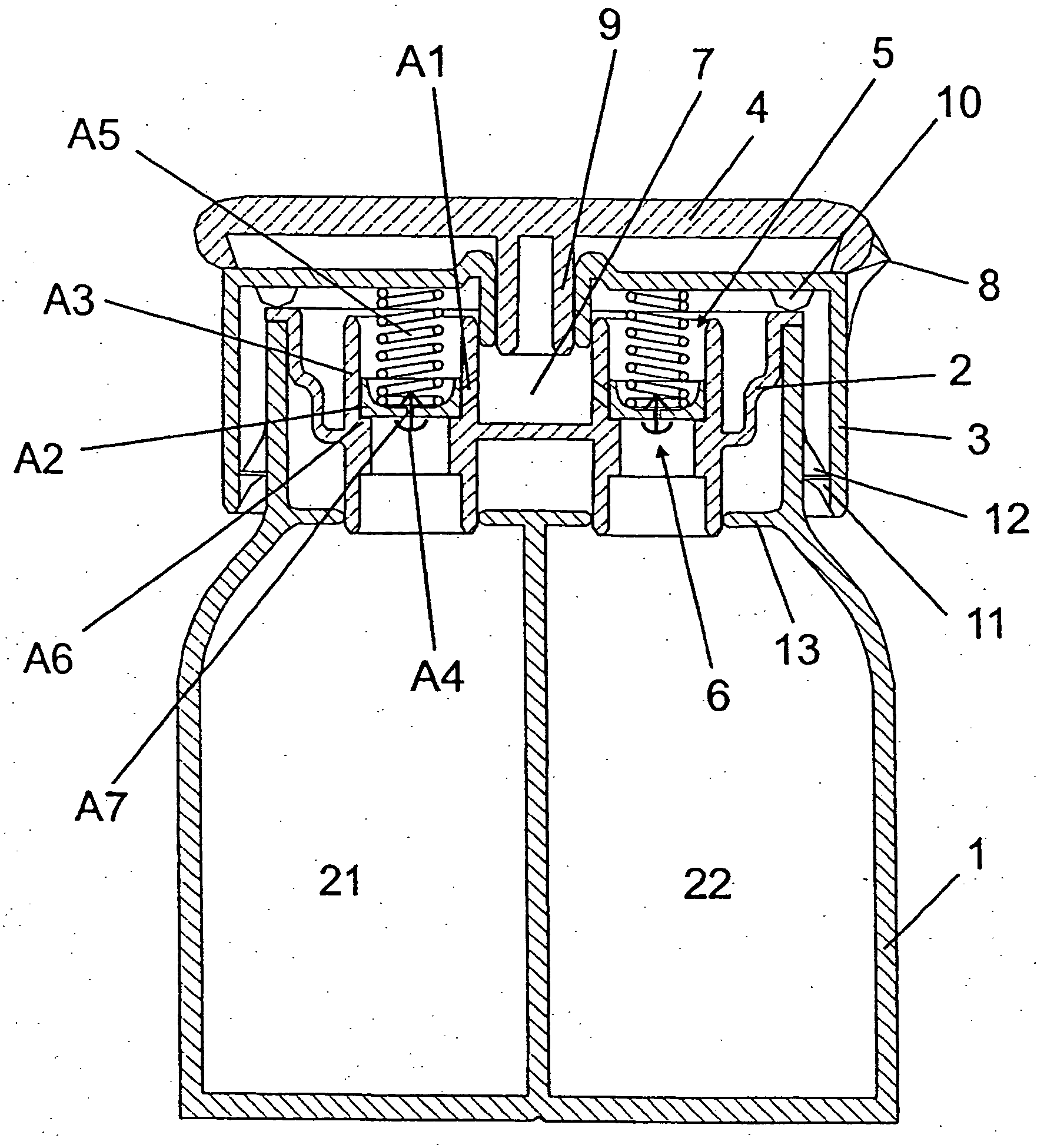

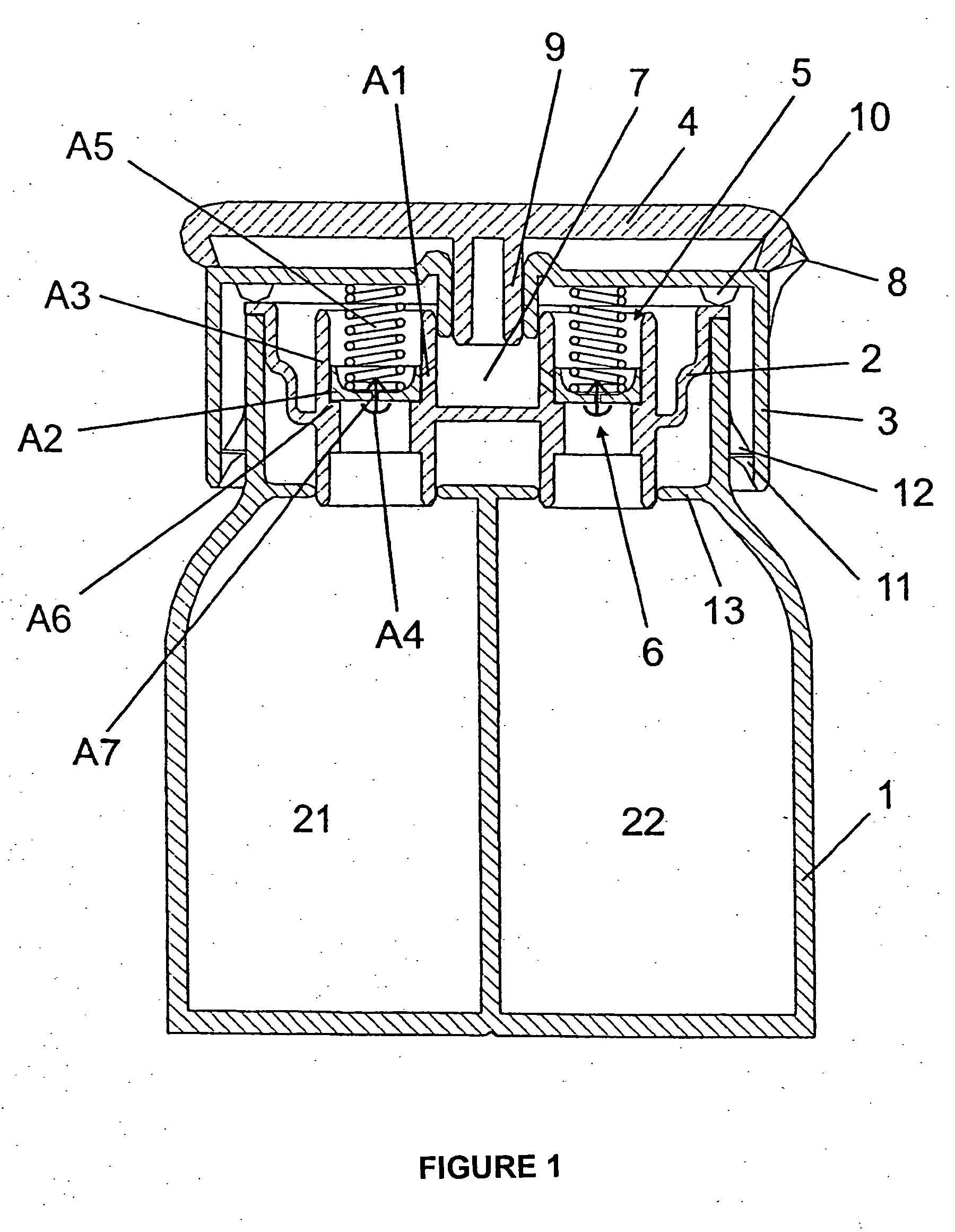

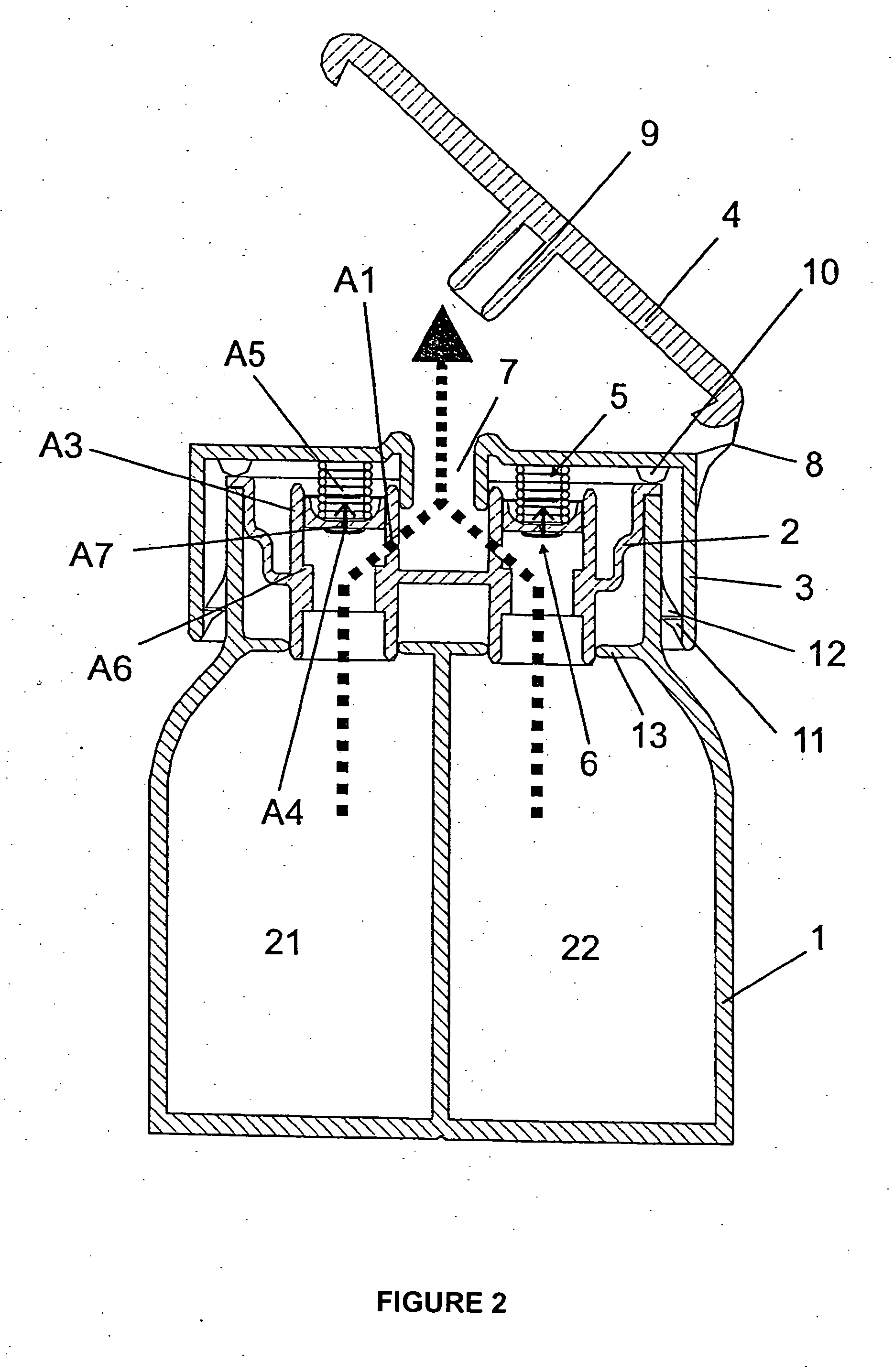

[0056] An illustrative embodiment of the invention is shown in FIG. 1. The figure shows a two-chamber container comprising of a container body 1 forming the two product chambers 21 and 22, a container insert 2, and a container attachment part 3. The illustrated multi-part configuration of the container is advantageous for production and is indicated here only by way of example. One-part container configurations, and multi-part container configurations of different structures, are also advantageous in the context of the invention. The container can additionally be closed by a lid 4.

[0057] The discharge of product from the product chambers can in each case be controlled with valve devices 5. For pressure compensation between the interior of the container and the exterior of the container, a valve device 6 is provided for readmission of air (air readmission valve device).

[0058] The valve device 5 for discharge of product is used to seal the product discharge opening A1 and, in the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com