Electrical connection assembly with unitary sealing and compression ring

a technology of unitary sealing and compression ring, which is applied in the direction of branching pipes, cable terminations, mechanical equipment, etc., can solve the problem of not being able to achieve positive electrical grounding of conduits at all times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

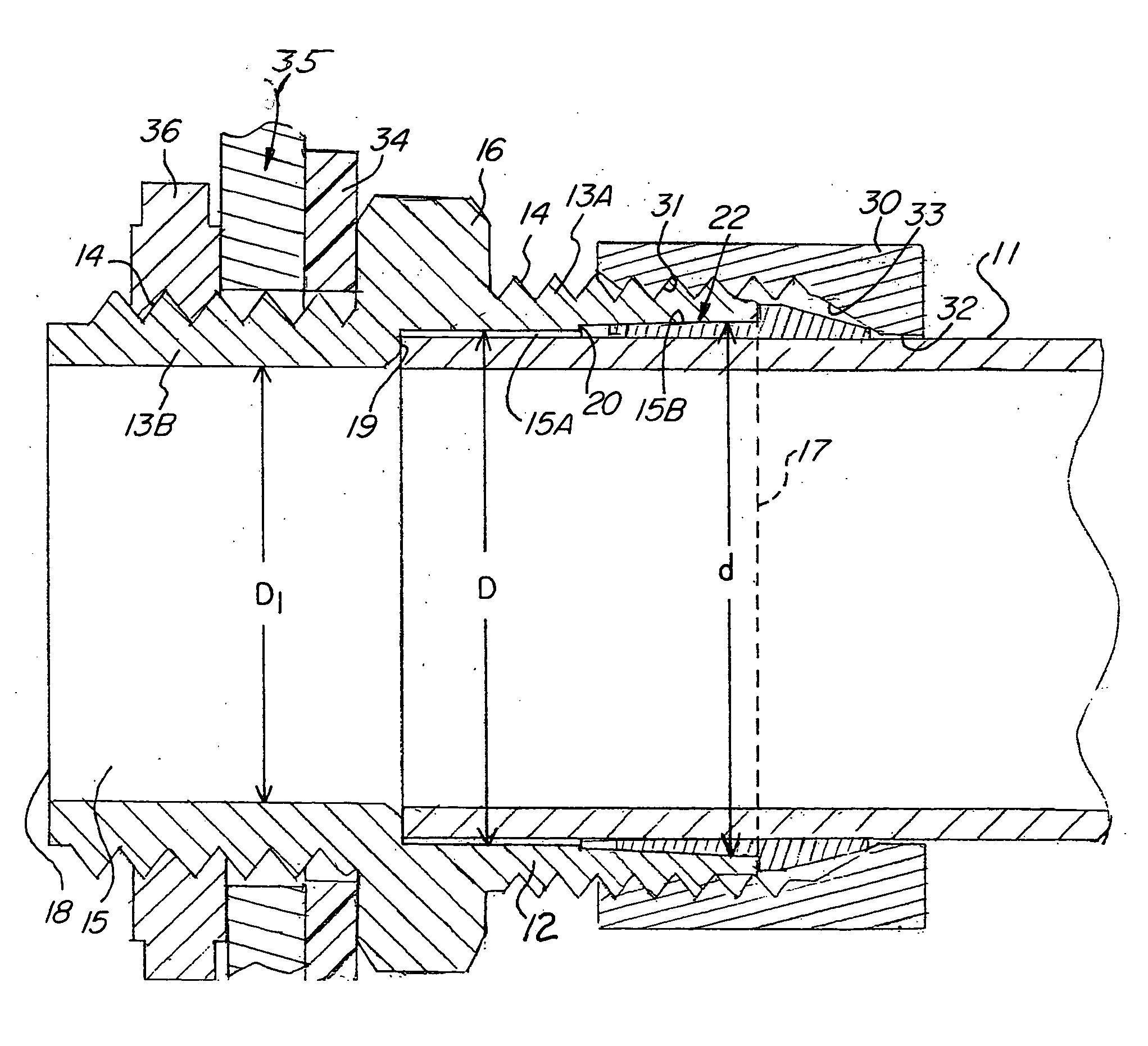

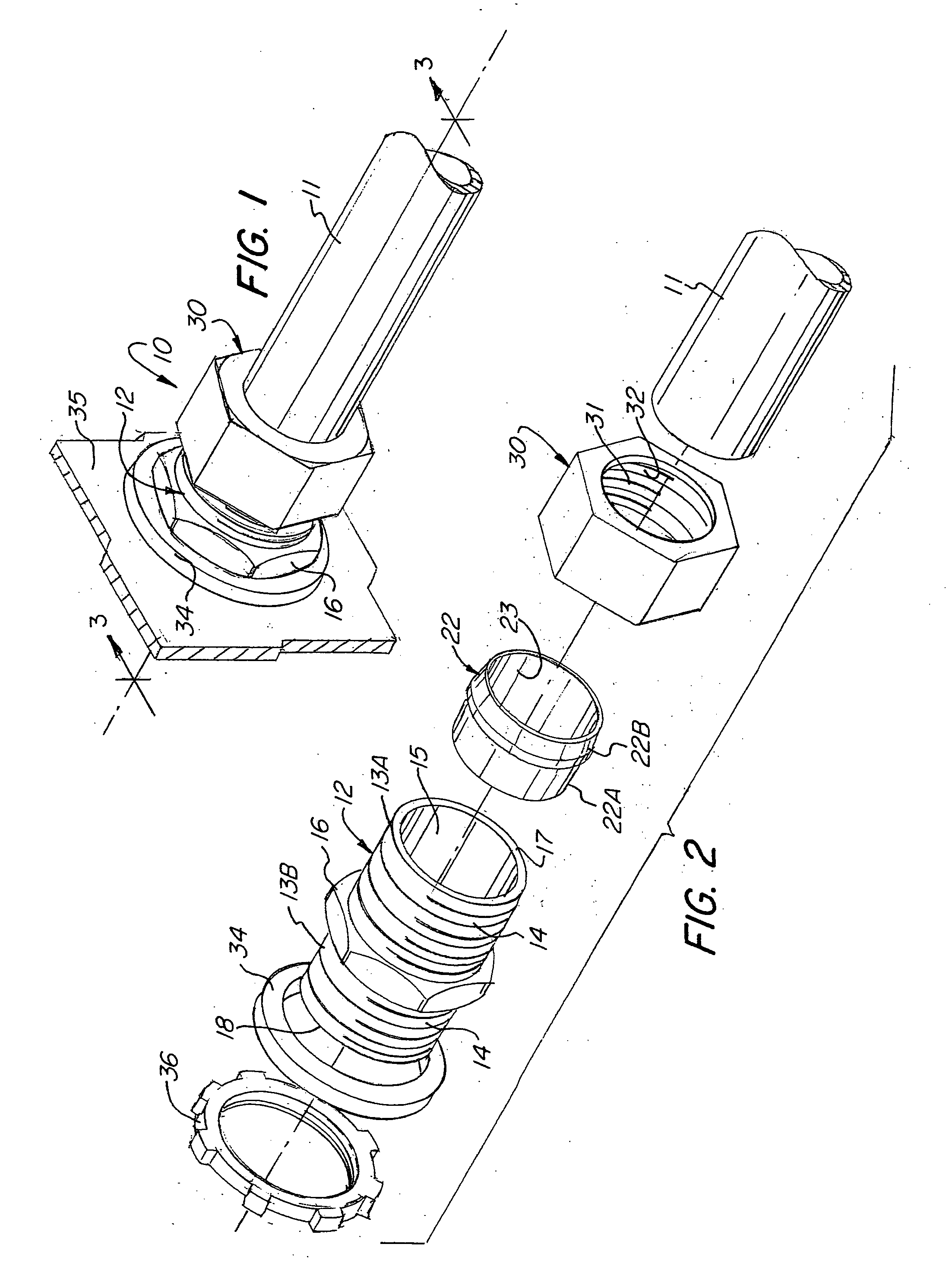

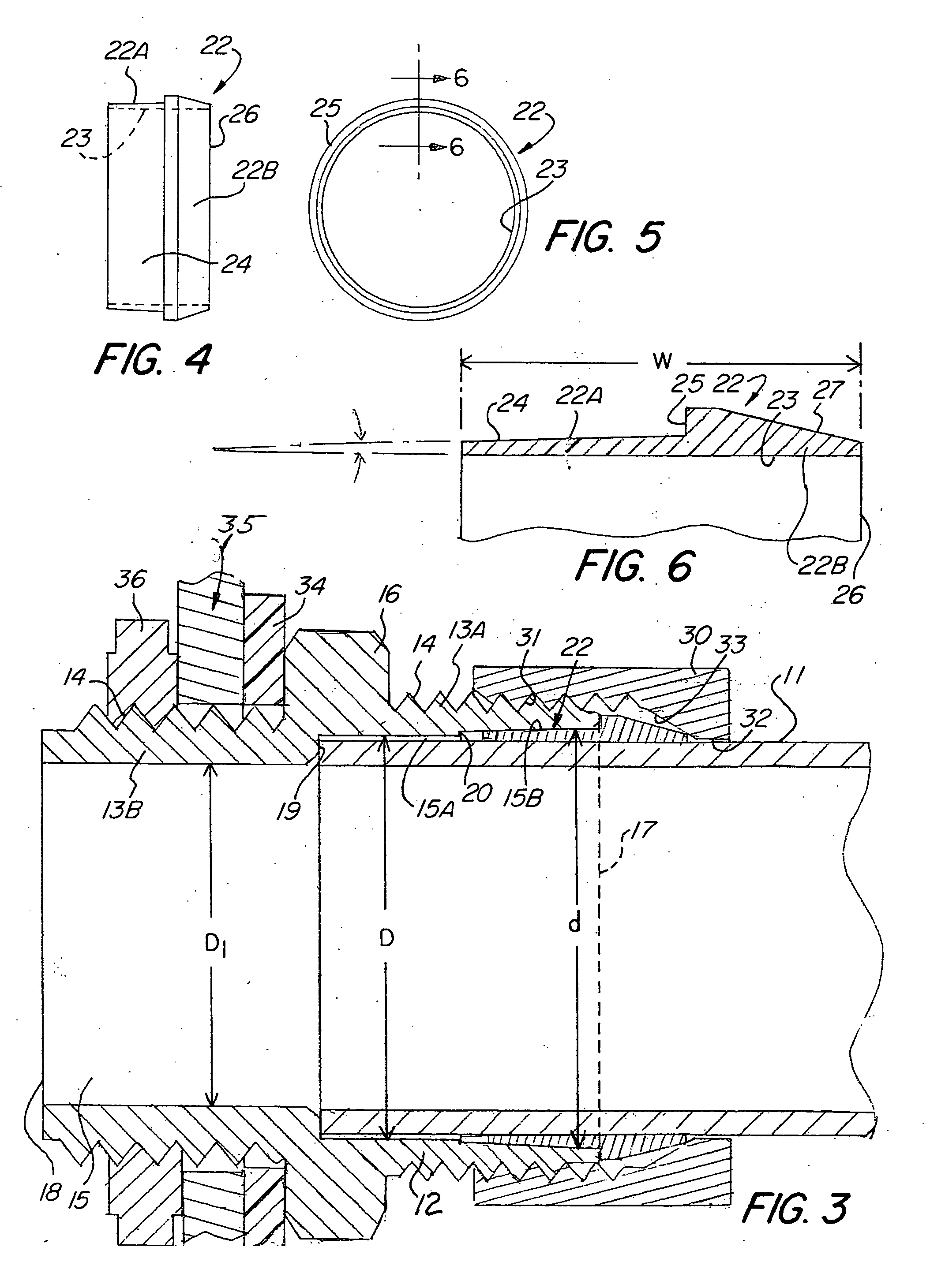

[0019] Referring to the drawings, there is illustrated in FIGS. 1 and 2 a connection assembly embodying the invention. A connection assembly as broadly used herein encompasses a connector assembly 10, by which an electric metallic conduit 11 is connected to an electrical junction box 35 as shown in FIG. 1, or coupling assembly 40 as shown in FIG. 7 for coupling two conduits 41A and 41B in end to end relationship.

[0020] The illustrated embodiment of the invention as depicted in FIGS. 1 to 6 is directed to a connector assembly 10 which includes a connector body 12 which is generally formed as zinc casting or other suitable metal. The connector body 12 includes an inlet end 13A and an outlet end 13B. In the illustrated embodiment of FIGS. 1 and 2, the outer surfaces of the inlet end 13A and outlet end 13B are provided with suitable external threads 14. The connector body 12 also includes a through bore 15, as will be hereinafter described in more detail. Intermediate the inlet end 13A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com