Spilway with improved dissipation efficiency

a technology of dissipation efficiency and pipeline, applied in the field of civil engineering, can solve the problems of large increase of flow discharge, loss of excess kinetic energy, and significant increase of non-dissipated kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

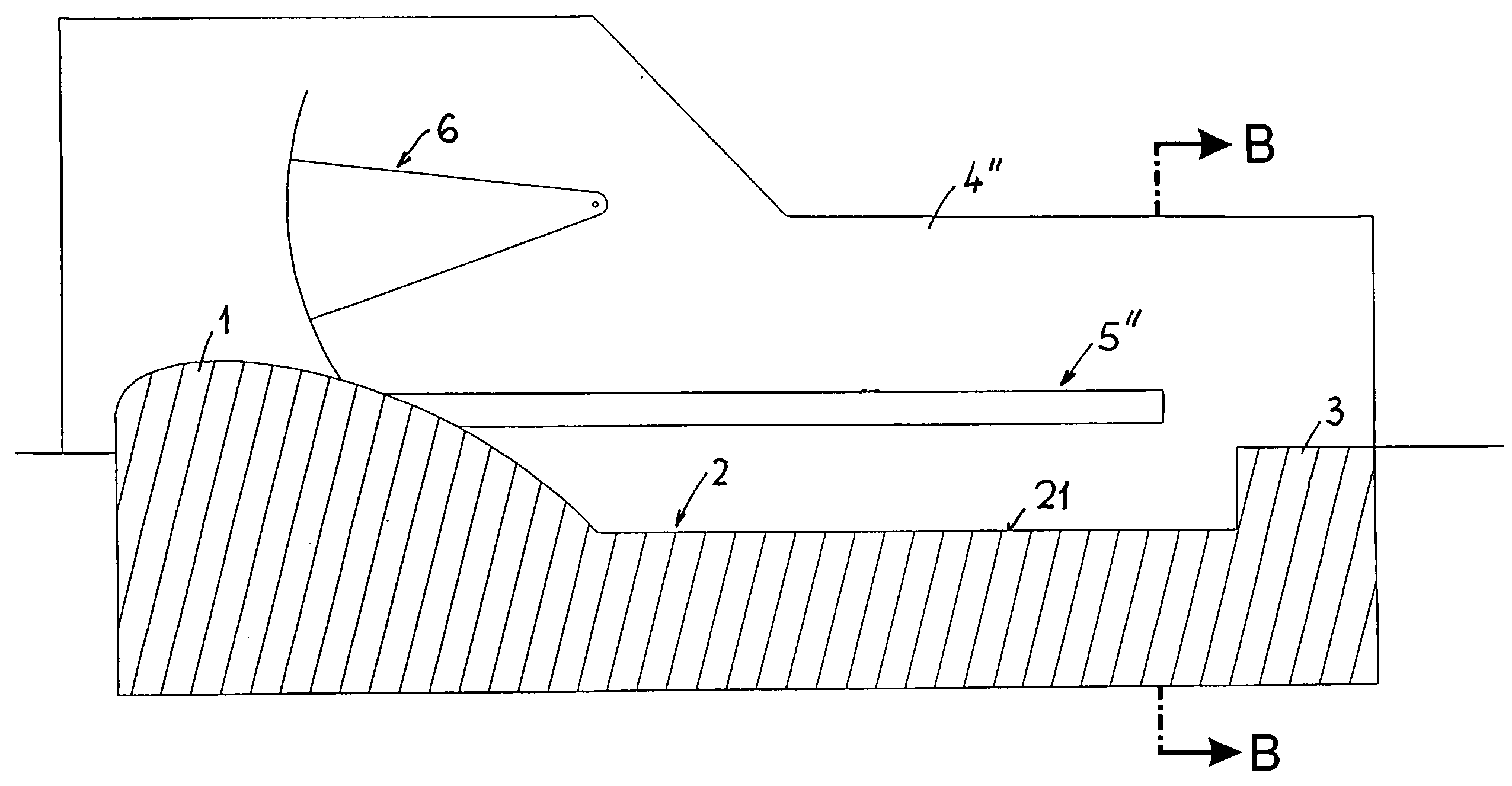

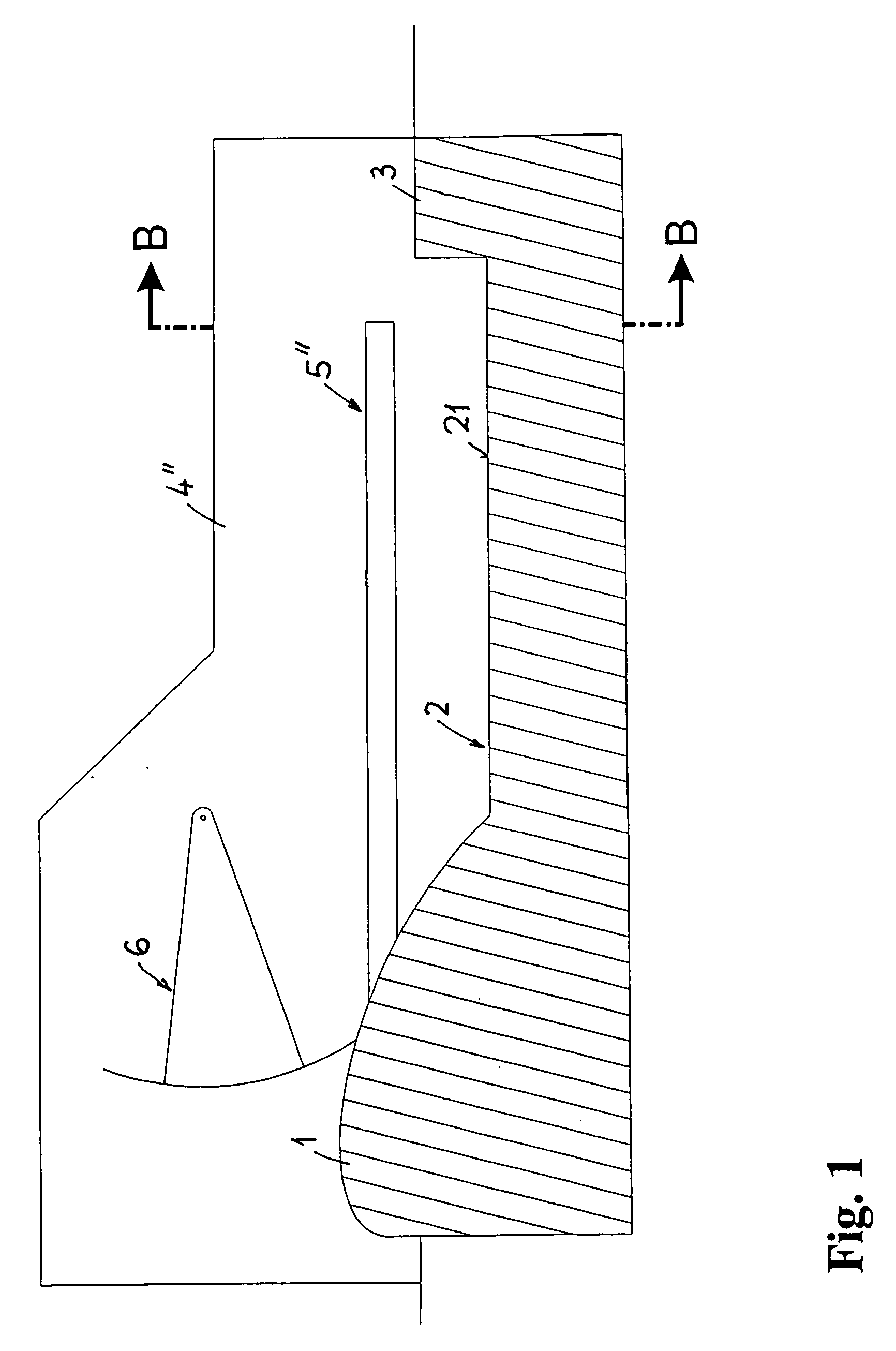

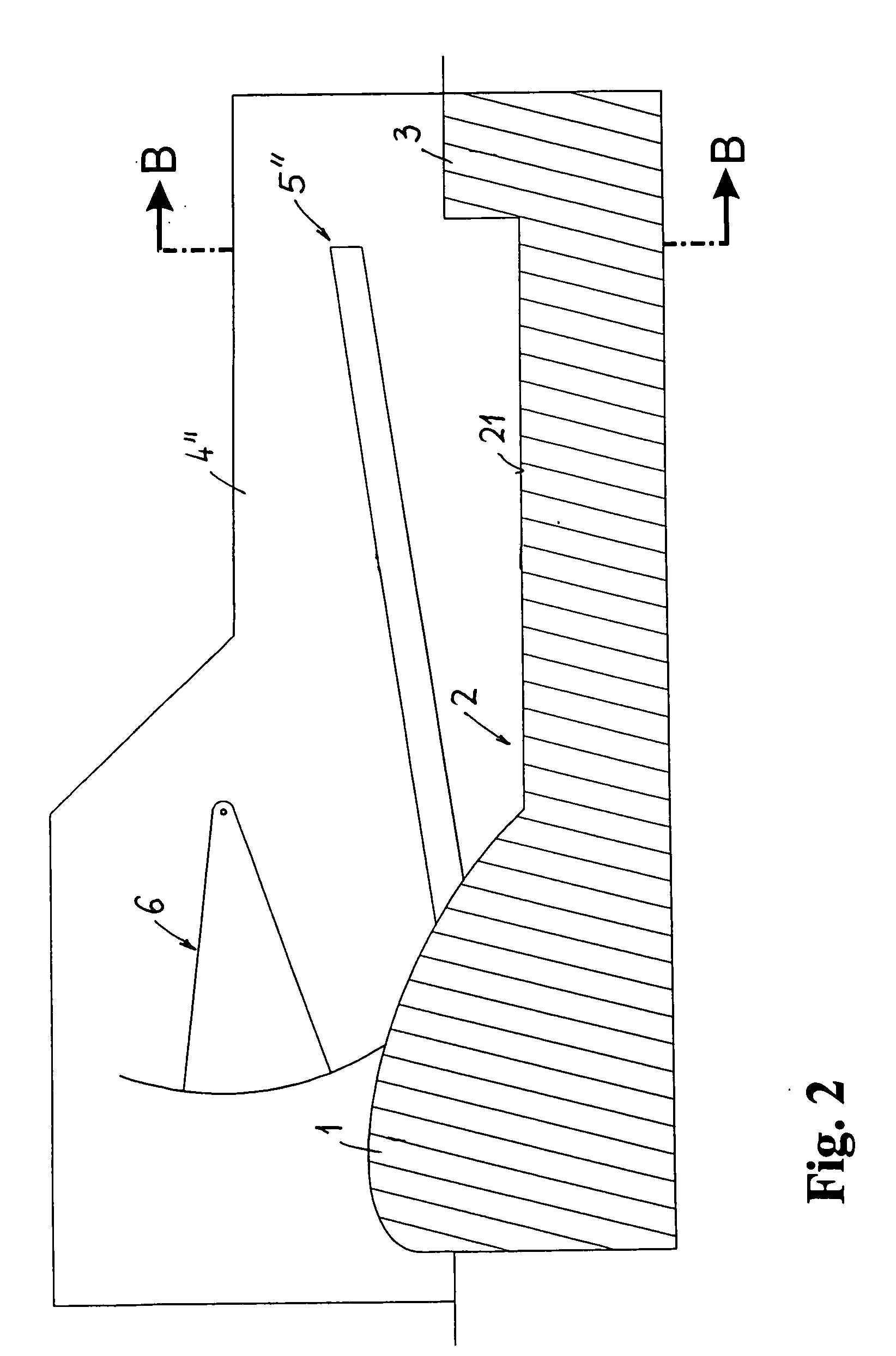

[0086] The spillway, e.g. of a hydro power plant weir or similar hydrauic structure with the improved dissipation efficiency according to the invention is presented on the FIG. 1 in the longitudinal cross-section along the plane A-A according to FIGS. 11 and / or 12, and on FIG. 11 and 12 in the transversal section in the section B-B according to FIG. 1 or rest FIGS. 2 to 10. The spillway—when observed in the flow direction—in principle consists of overflow spillway 1, stilling basin 2 with the end sill 3 or without it, and is on sides constrained with the side walls 4′, 4″, that are running in the flow direction.

[0087] If needed or depending on the purpose of the spillway, the gate 6 or similar closing device may be positioned in the field of spillway area, that are quite schematically presented in FIGS. 1 to 10, but in a quite understandable manner for those skilled in the art. At the construction of the spillway, presented on FIG. 12, the sidewalls 4′, 4″ are flat and vertical, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com