Packaging for an optical sheet and a packaging method of the same

a technology of optical sheets and packaging methods, applied in the direction of packaging goods, instruments, containers preventing decay, etc., can solve the problems of contaminating the surface of the polarizer, affecting the quality of the optical sheet, so as to reduce the quantity of packaging components and reduce the material cost and packaging time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Reference will now be made in detail to the present preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers are used in the drawings and the description to refer to the same or like parts.

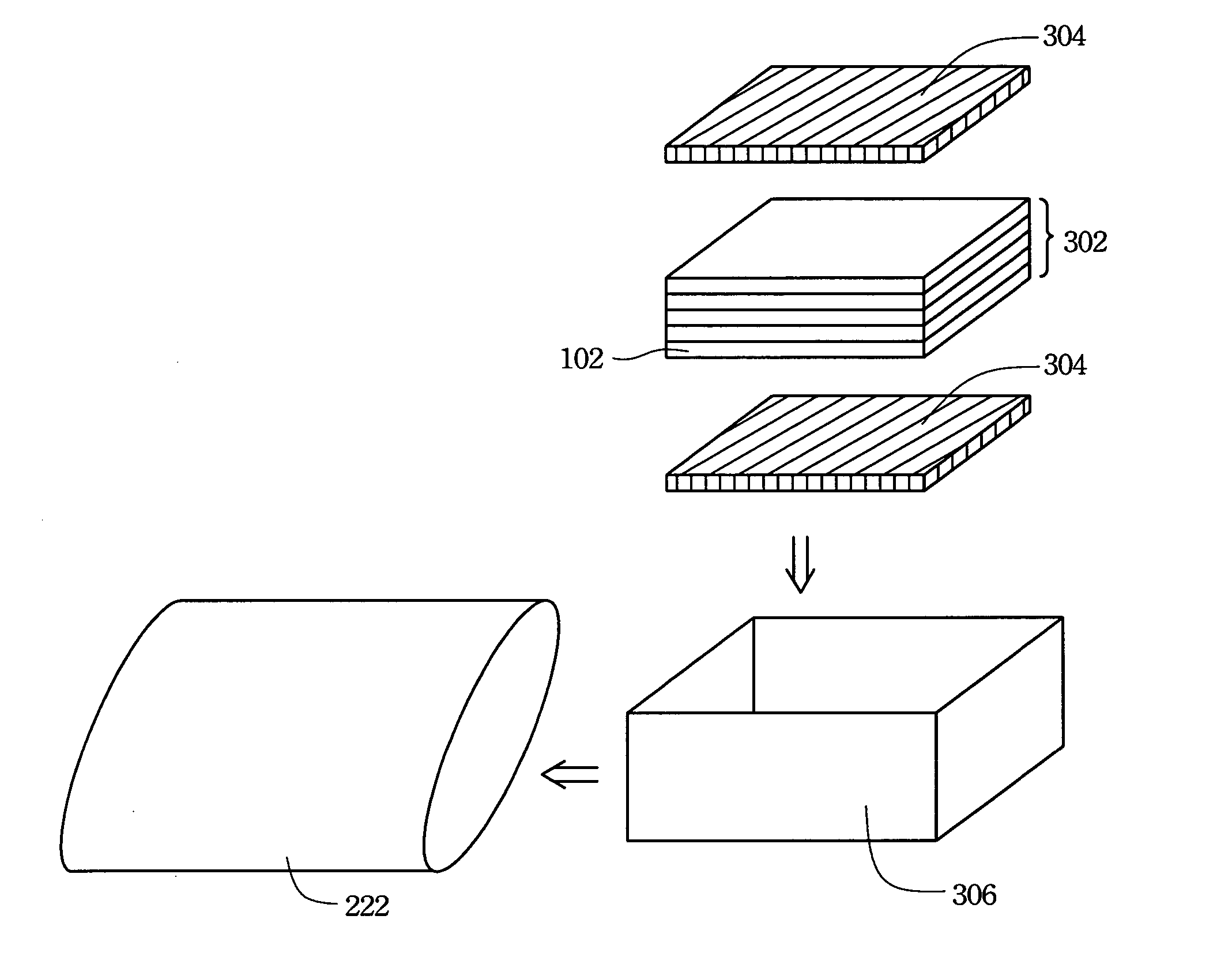

[0029] The invention uses the packaging essentially having two packaging components to replace the conventional packaging having at least three packaging components, thus decreasing the manufacturing cost and enhancing the manufacturing efficiency and yields. Moreover, the invention adds a specific weight percent of silicone into the material of the packaging component which is in contact with the optical sheet, in order to reduce the coefficient of friction between the inner surface of the packaging component and the optical sheet, and thereby mitigates the contamination caused by the adhesive layer being brought out.

[0030]FIG. 2A illustrates a schematic view of one preferred embodiment of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| adhesive | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com