Composition curable with actinic energy ray and use thereof

a technology of actinic energy rays and curable compositions, applied in the field of actinic energy raycurable compositions, can solve the problems of limiting the application of ultraviolet curable compositions, not meeting the scratch resistance of cured products, etc., and achieve excellent scratch resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

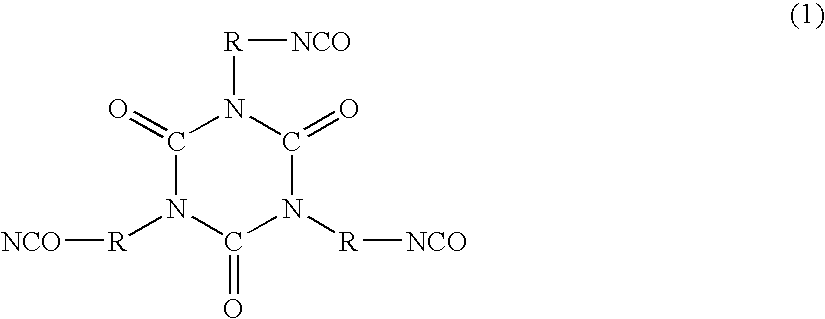

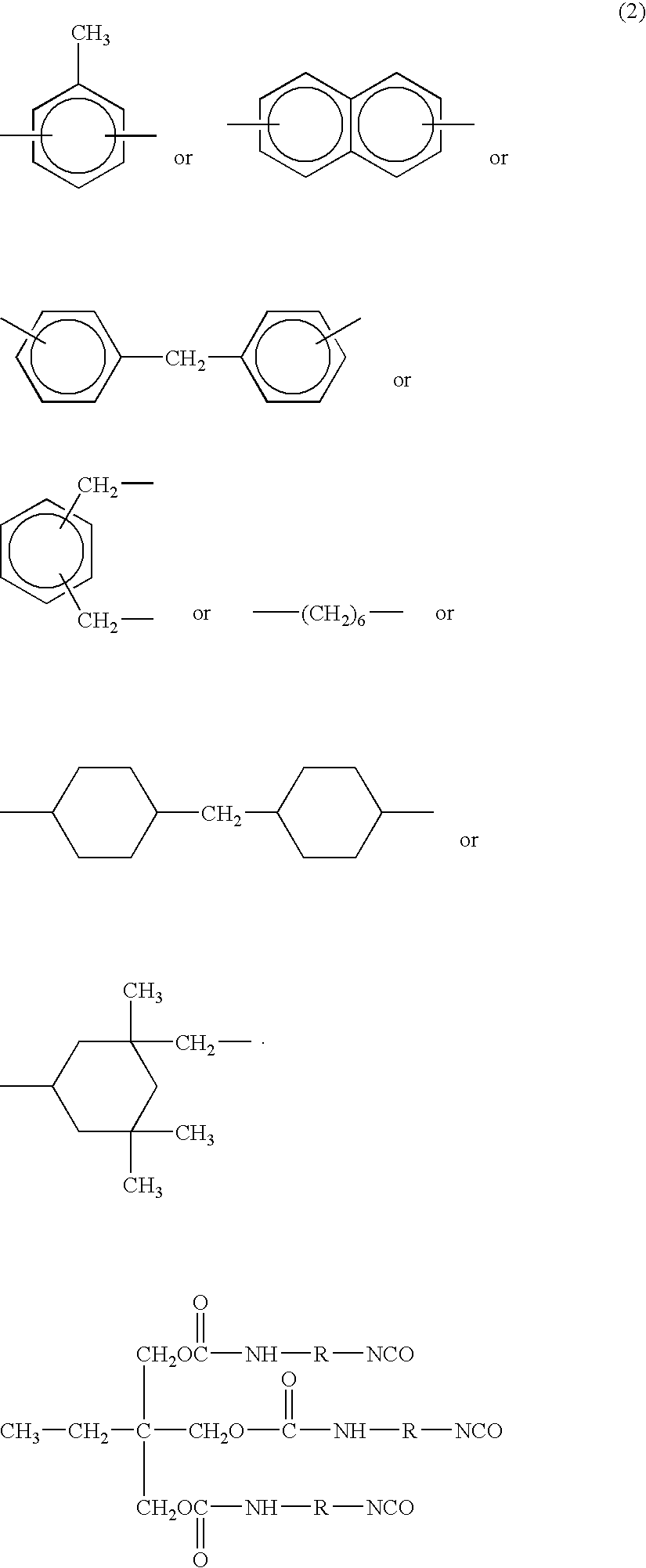

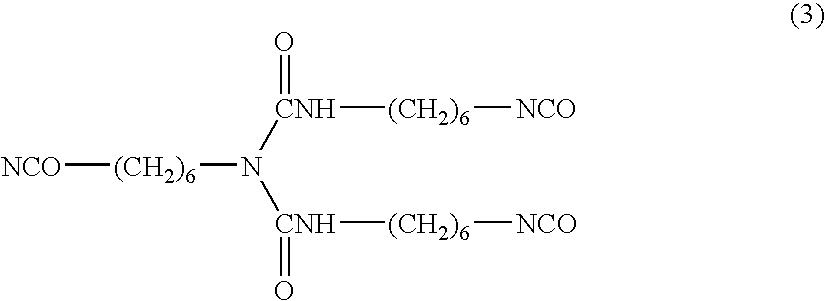

[0011] First, an actinic energy ray-curable composition according to a first embodiment of the present invention is described.

[0012] The actinic energy ray-curable composition according to the first embodiment contains two or more kinds of urethane(meth)acrylates different from one another in the number of repetitions of a caprolactone unit per one residue of a polycaprolactone-modified alkyl(meth)acrylate.

[0013] The average number of repetitions per one molecule of the urethane(meth)acrylate relative to the number of repetitions of the caprolactone unit per one residue of the polycaprolactone-modified alkyl(meth)acrylate is preferably in the range of from 1 to 5, more preferably in the range of from 1 to 2.5. The maximum difference in the number of repetitions of the caprolactone unit per one residue of the polycaprolactone-modified alkyl(meth)acrylate between two kinds of the urethane(meth)acrylates is preferably 9 or less, more preferably in the range of from 4 to 9.

[0014] Eac...

second embodiment

[0035] Next, an actinic energy ray-curable composition according to a second embodiment is described mainly with respect to points differing from the actinic energy ray-curable composition according to the first embodiment.

[0036] The actinic energy ray-curable composition according to the second embodiment contains a urethane(meth)acrylate obtained by reacting an organic isocyanate with two or more kinds of polycaprolactone-modified alkyl(meth)acrylates different from each other in the number of repetitions of a caprolactone unit per one molecule.

[0037] The average of the number of repetitions of the caprolactone unit per one molecule of the polycaprolactone-modified alkyl(meth)acrylate is preferably in a range of from 1 to 5, more preferably in a range of from 1 to 2.5. The maximum difference in the number of repetitions of the caprolactone unit between two kinds of the polycaprolactone-modified alkyl(meth)acrylates is preferably 9 or less, more preferably in a range of from 4 to...

third embodiment

[0043] Next, an actinic energy ray-curable composition according to a third embodiment is described mainly with respect to points differing from the actinic energy ray-curable compositions according to the first and second embodiments.

[0044] The actinic energy ray-curable composition according to the third embodiment contains a urethane(meth)acrylate obtained by reacting an organic isocyanate with a polycaprolactone-modified alkyl(meth)acrylate, and a urethane (meth)acrylate obtained by reacting an organic isocyanate with a hydroxyalkyl(meth)acrylate.

[0045] Specific examples of the hydroxyalkyl(meth)acrylate include a compound represented by the following general formula (5) such as hydroxyethyl(meth)acrylate, hydroxypropyl (meth)acrylate, and hydroxybutyl(meth)acrylate.

[0046] R represents H or CH3 and 1 is an integer of 1 to 10.

[0047] When generically naming the polycaprolactone-modified alkyl(meth)acrylate and the hydroxyalkyl(meth)acrylate as a (meth)acrylate monomer, the hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com