Unsymmetrical profile threads for use in a positive displacement motor housing

a positive displacement motor and profile technology, applied in the direction of threaded fasteners, screw threaded joints, borehole/well accessories, etc., can solve the problems of reducing the wall thickness of the housing, particularly the bending stress fatigue failure of the threaded connection, etc., to reduce the fatigue experienced by the threaded connection, increase the root radius, and reduce the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

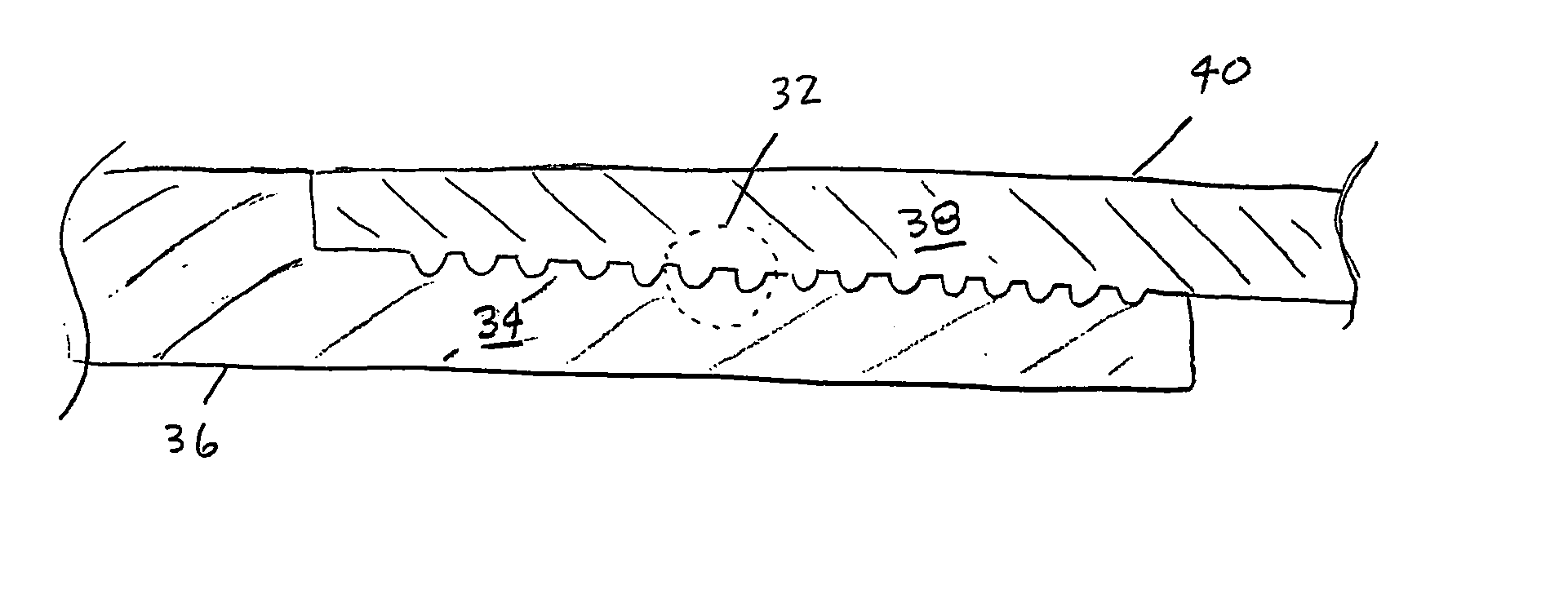

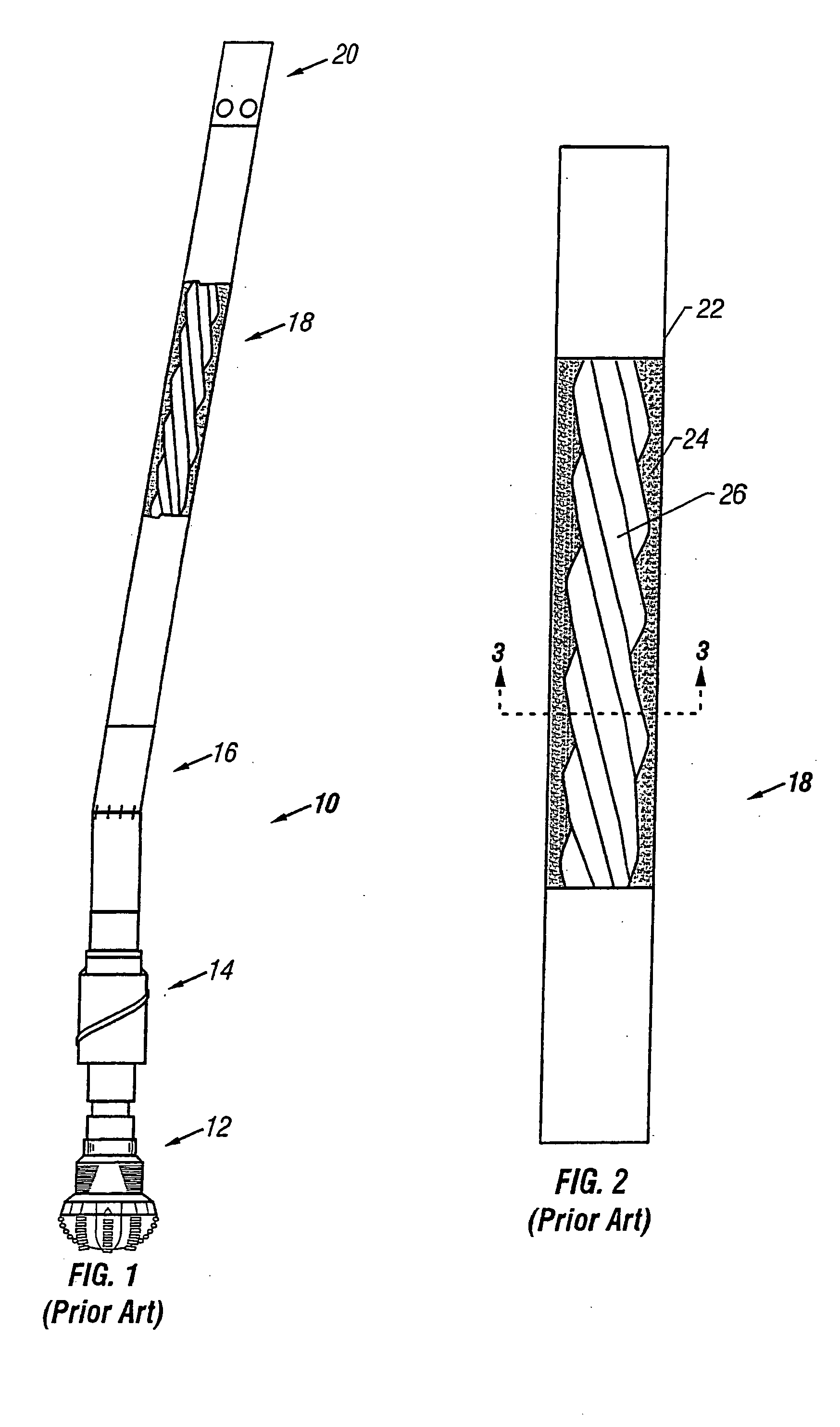

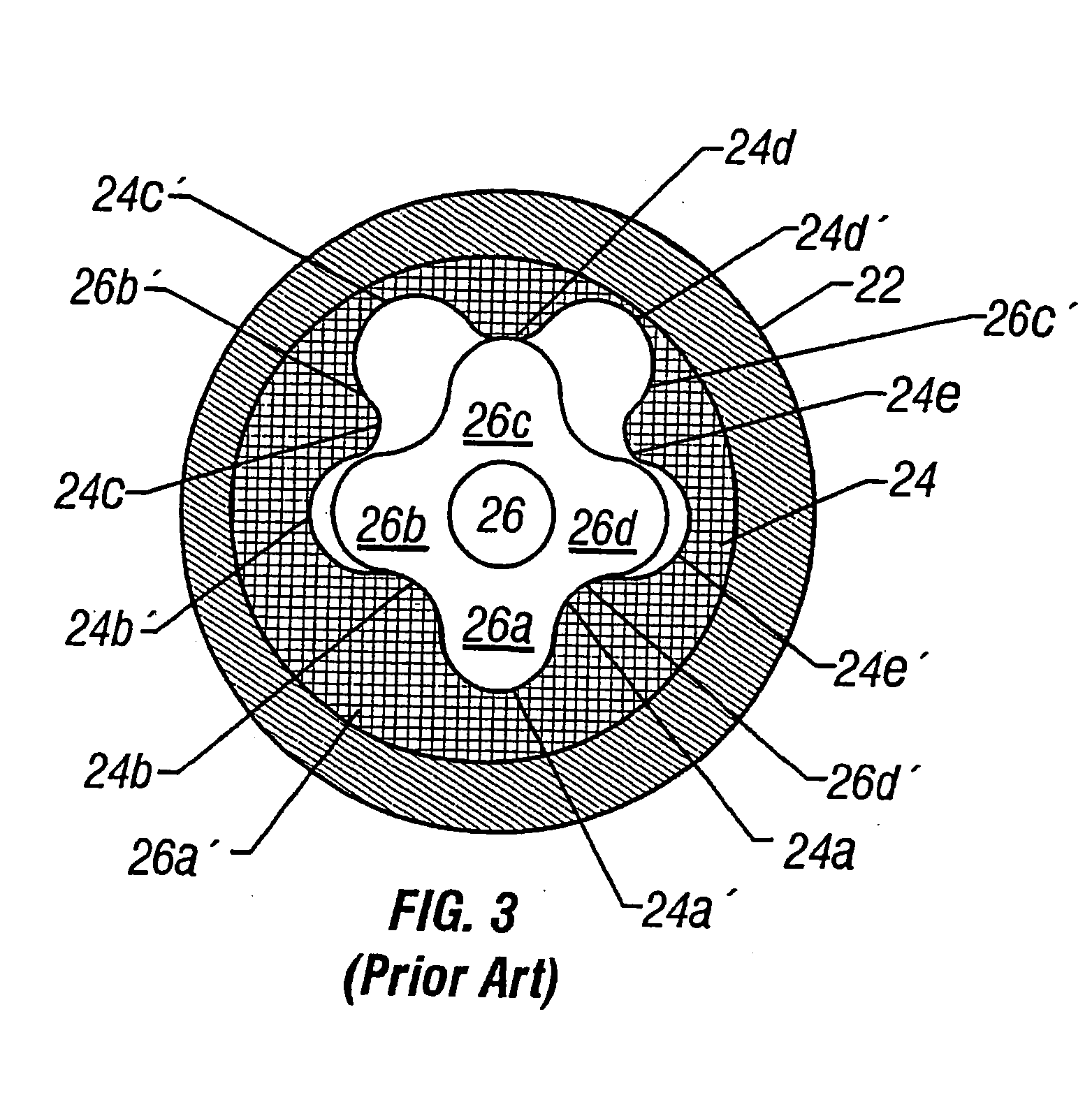

[0020]FIGS. 4 and 5 show a prior art conventional thread profile 30 that is used to connect stator housings of a positive displacement motor (PDM). FIG. 4 shows the threaded connection 32 on the pin-side 34 of the stator housing 36, while FIG. 5 shows an enlarged view of the threaded connection 32. As used in this application, the term “pin-side” refers to the end 34 of the stator housing 36 that is threadably received by the “box-side”38 of the adjacent housing / drill string component 40.

[0021] The illustrated conventional thread profile 30 of the threaded connection 32 is a tapered thread with a symmetrical V-profile and a symmetrical root radius 42. The thread root radius 42 governs the stress concentration and the level of fatigue resulting from the bending and axial stresses experienced in the threaded connection 32 during the drilling process. For a given pitch diameter and profile angle, the root radius 42 is limited by the useful mating area and the thread pitch P.

[0022]FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com