Supple penetration resistant fabric and method of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The following detailed description of the structure of various embodiments of the penetration resistant fabric of this invention enables any person skilled in the art to make and use this invention and sets forth the best modes contemplated by the inventor for carrying out the invention. Various modifications of the described embodiments of the inventive fabric, however, will be readily apparent to those skilled in the art because the principles of the present invention are defined in this written description.

[0097] In this disclosure, embodiments of the fabric are sometimes referred to by the designation SF11, SF12, SF13, and so forth for ease of reference.

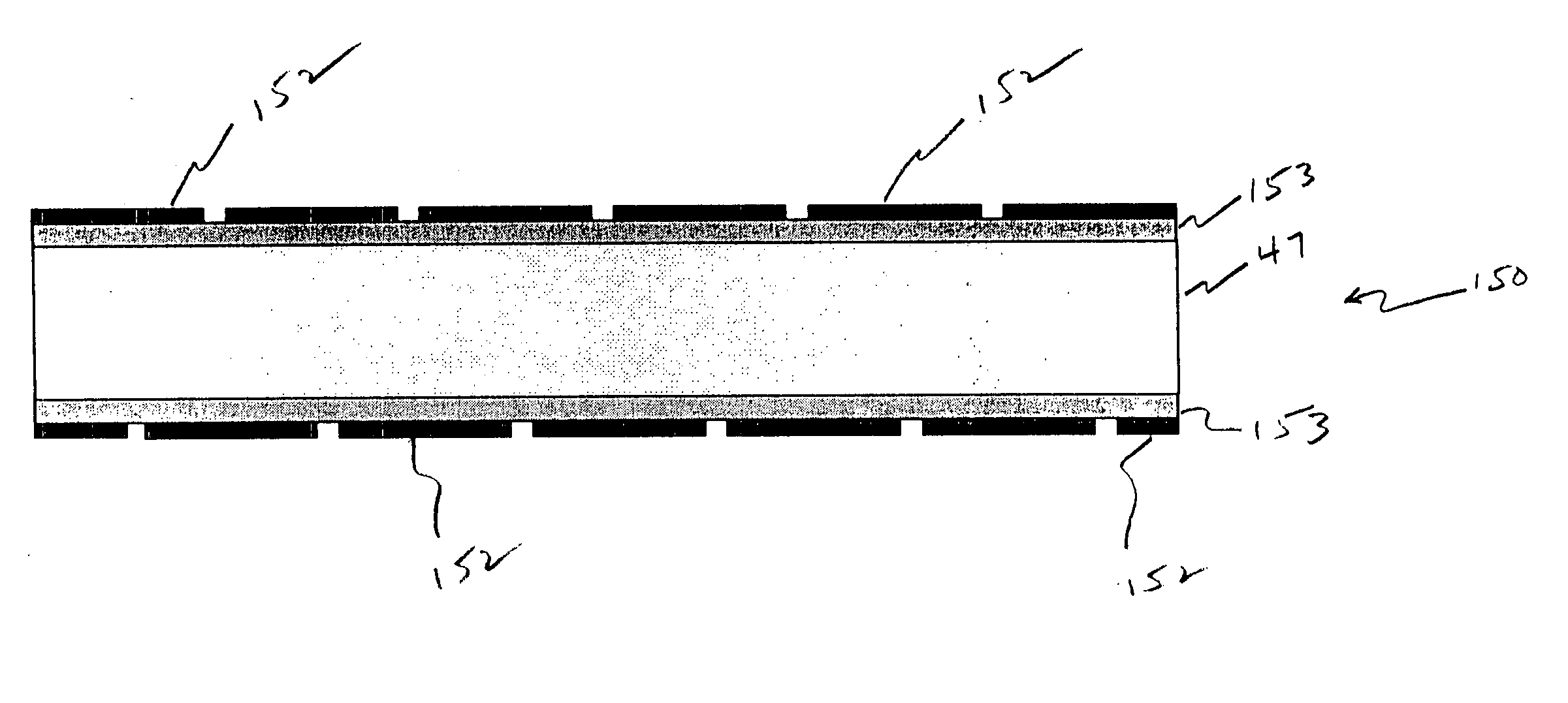

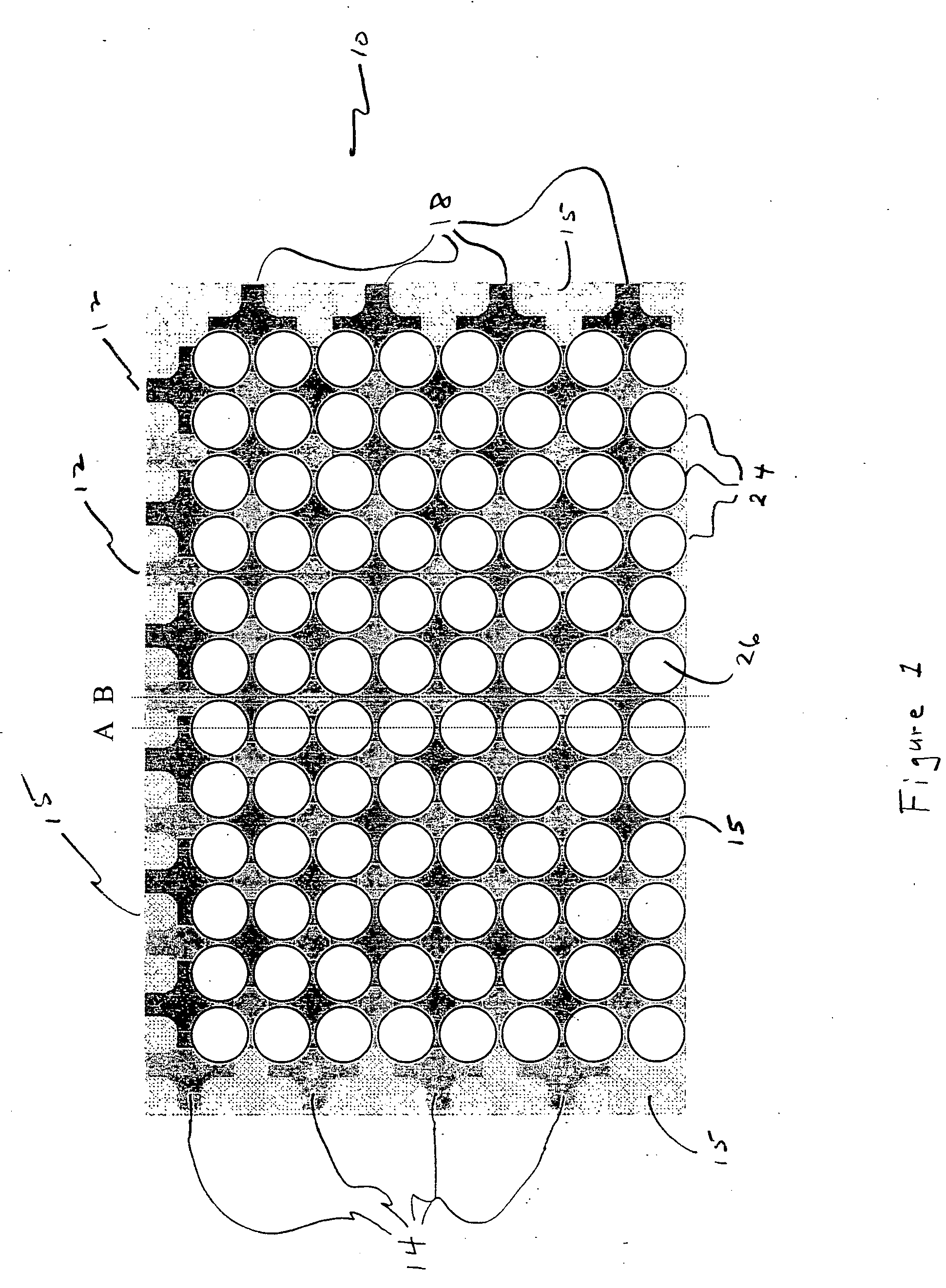

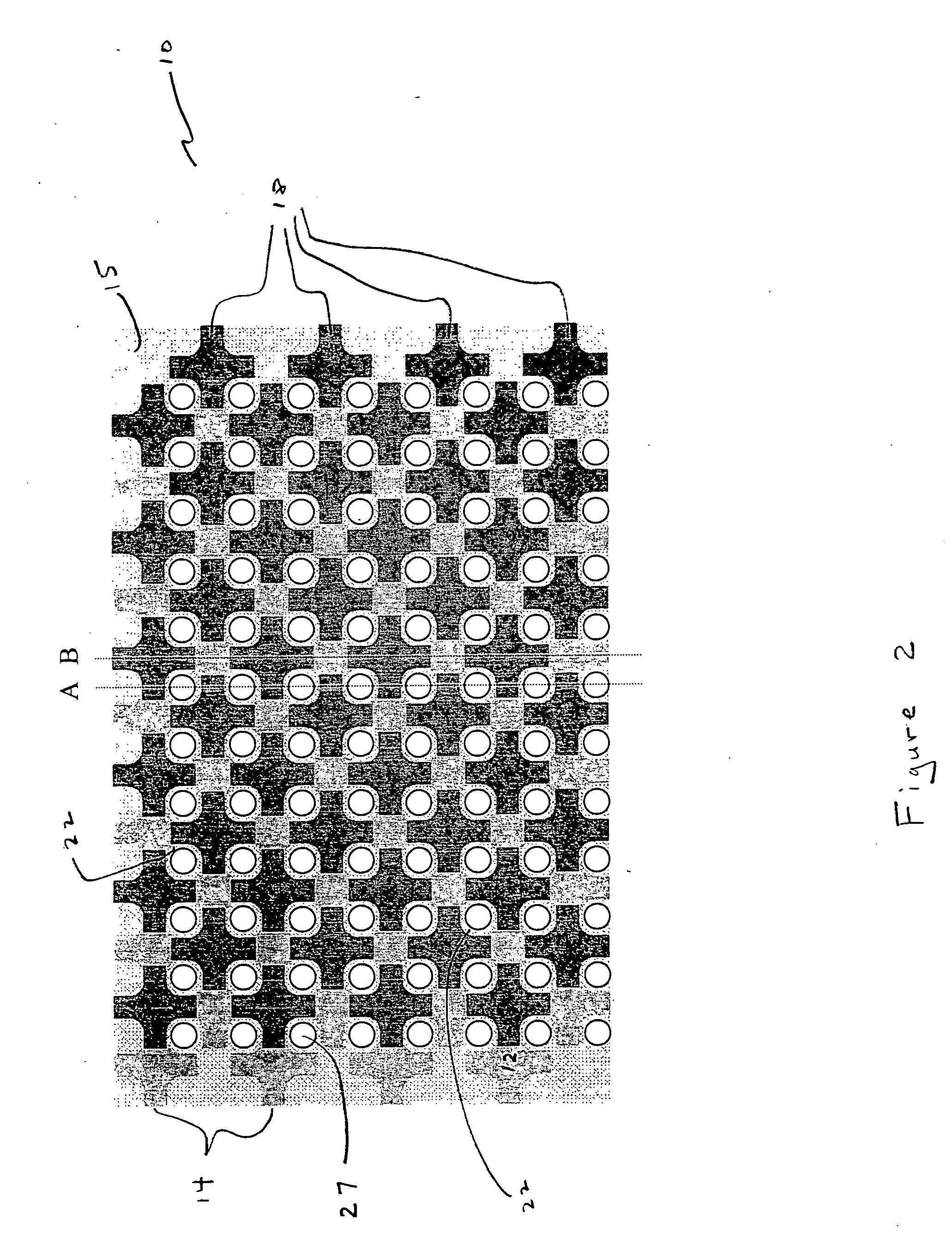

[0098]FIGS. 1 through 4 illustrate a three-layer fabric 10 embodiment, SF11, representing the inventive features of the present invention. As seen in FIGS. 1-3, identical cruciform-shaped guard plates 12 are spaced from each other and oriented in a first guard plate layer 14 with a connecting material 15. All four arms 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com