Method and device for x-ray inspection of tire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

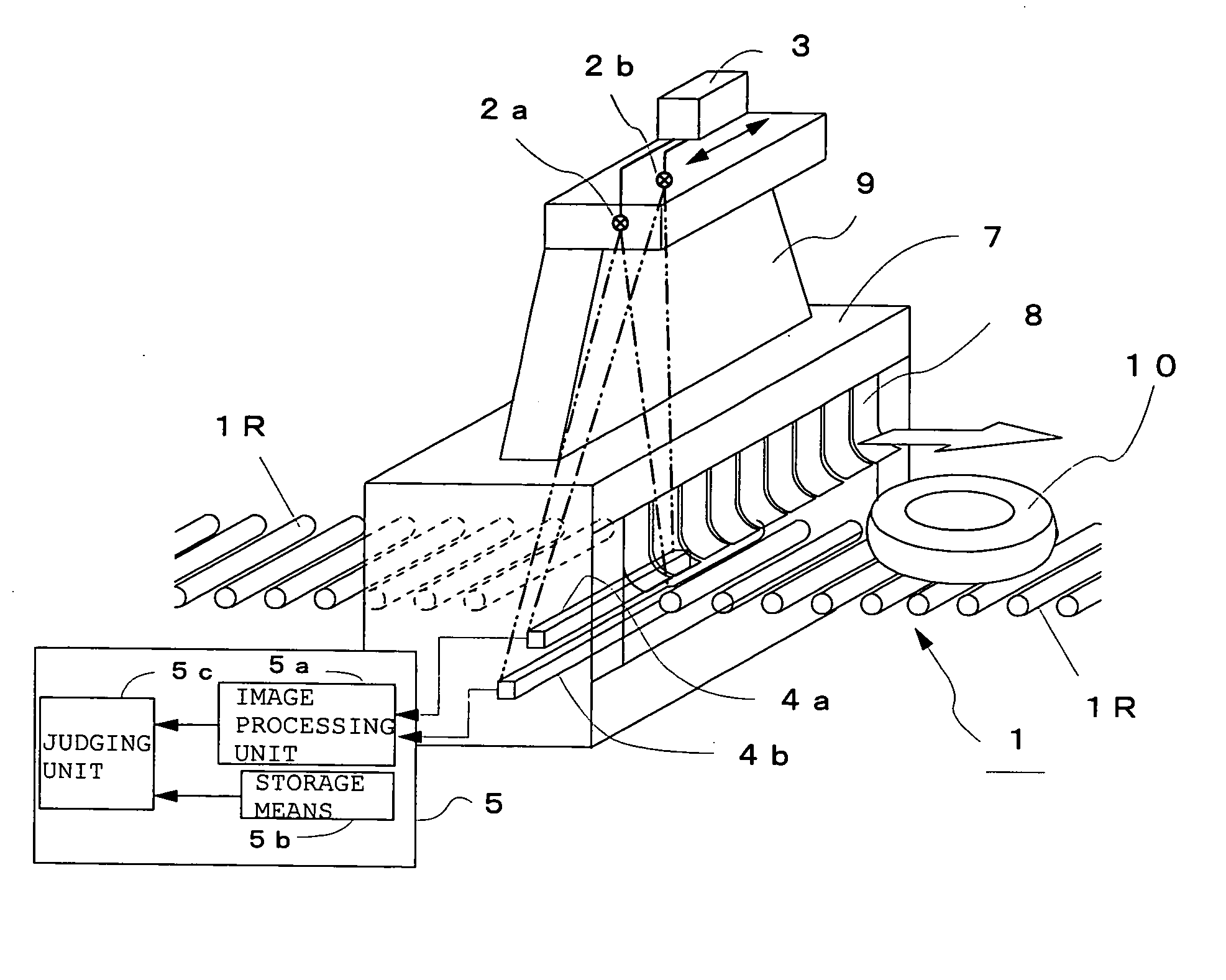

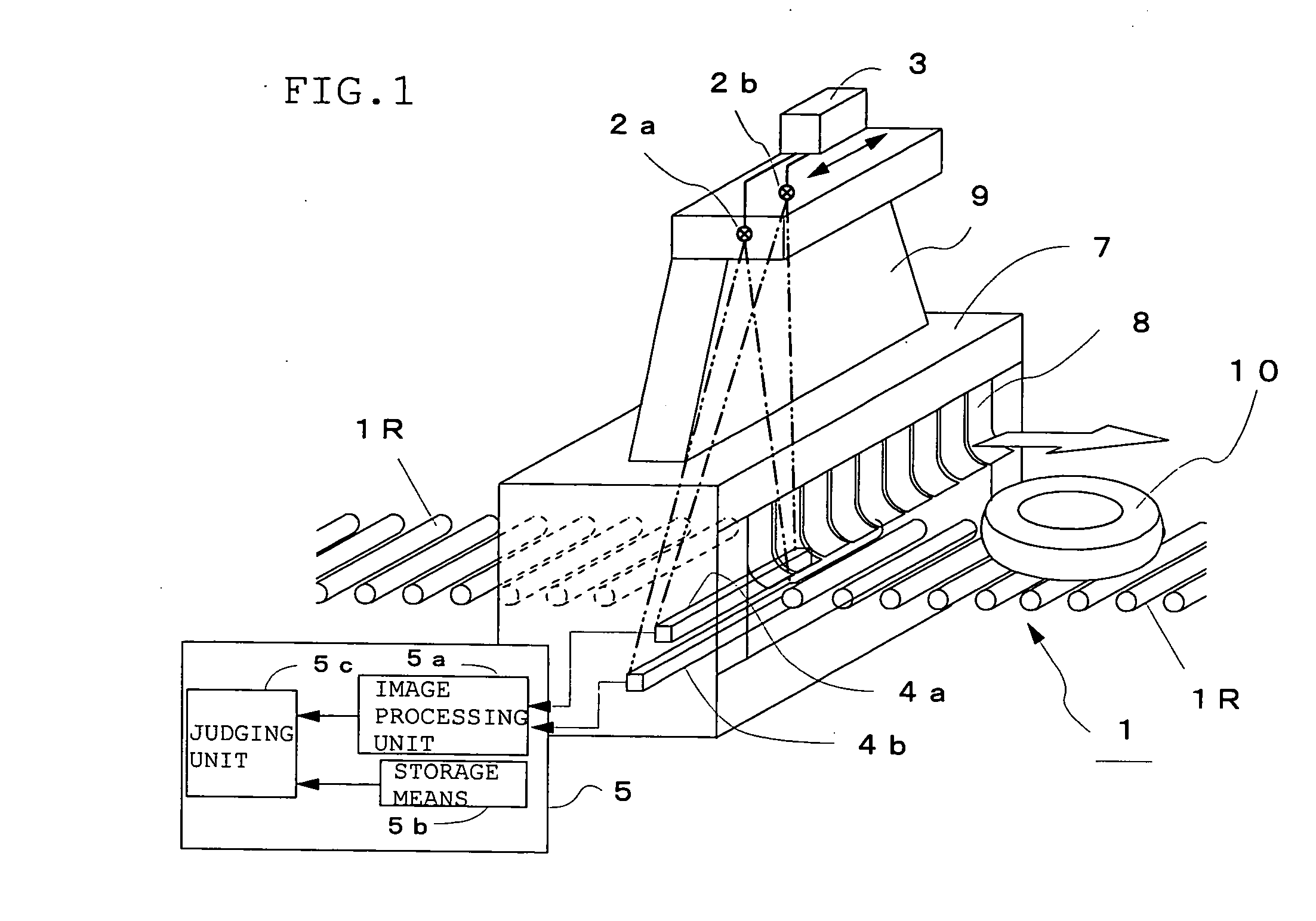

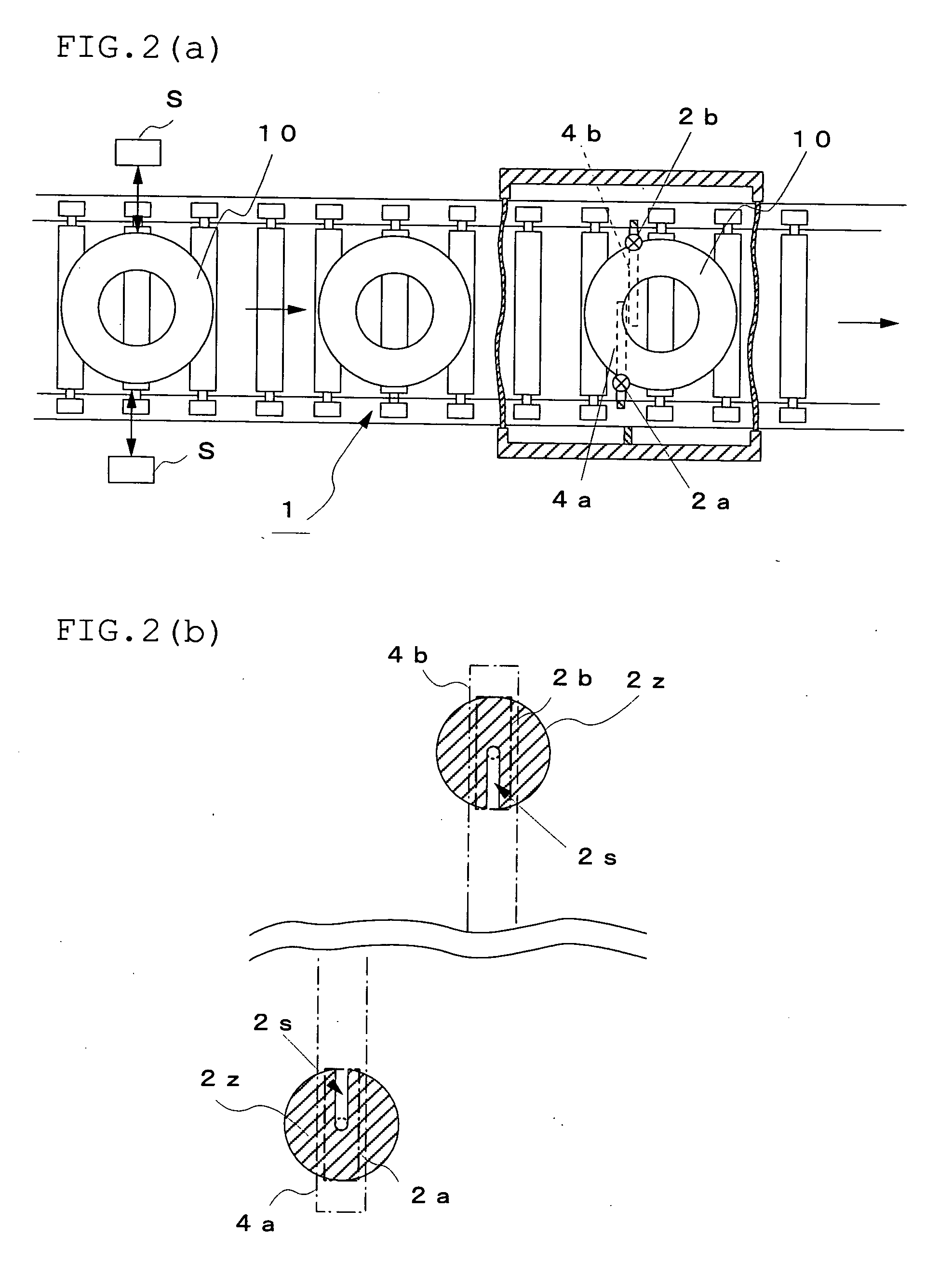

Image

Examples

example

[0057] As shown in FIGS. 5(a) and 5(b), 12 test pieces 20 formed by sandwiching four metal washers 21 arranged in a row at equal intervals between two acrylic boards 22 and 22 were arranged symmetrical about the center of a tire 10Z on the side surface of the tire (215 / 50 ZR17) having an aspect ratio of 50(%) and a transmission X-ray image of this tire 10Z was taken by the X-ray inspection apparatus of the present invention and shown in FIG. 6(a). A transmission X-ray image of the same tire Z taken by an X-ray inspection apparatus having only one X-ray source of the prior art is shown in FIG. 6(b). As obvious from comparison between FIGS. 6(a) and 6(b), since the dead area formed by the tread belt 12 is large in the apparatus of the prior art, only one out of the four washers 21 can be detected. In contrast to this, in the apparatus of the present invention, all the four washers 21 can be detected. Therefore, it is confirmed that the dead area becomes extremely small in the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com