Linear compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0040] It should be understood that linear compressors according to numerous preferred embodiments of the present invention may be proposed, although only the most preferred embodiments of the present invention will be hereinafter described.

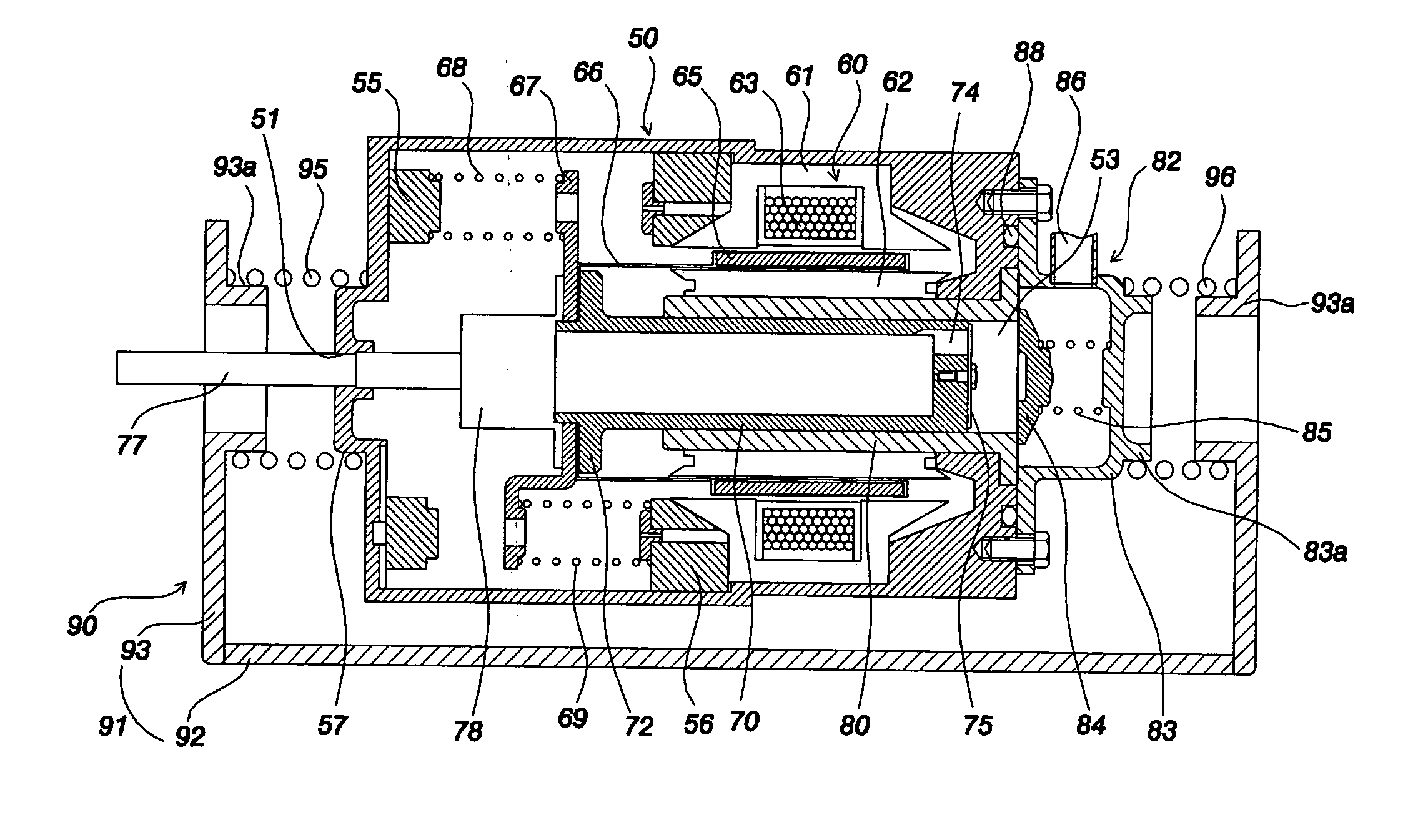

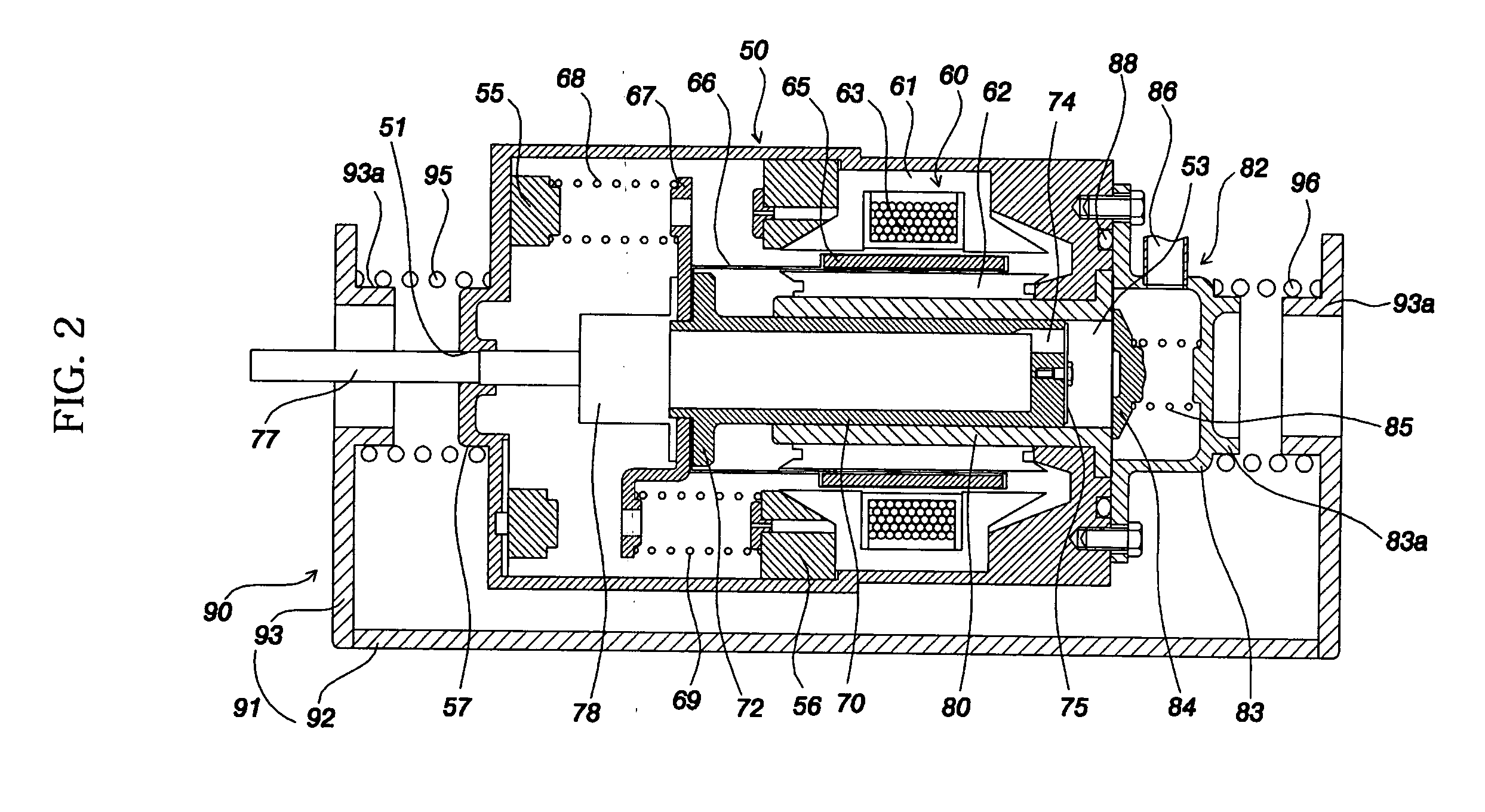

[0041]FIG. 2 is a longitudinal sectional view showing a linear compressor according to a preferred embodiment of the present invention.

[0042] As shown in FIG. 2, the linear compressor according to the present invention includes: a hermetically sealed container 50 having an inlet port 51 and an outlet port 53 formed therein; a linear motor 60 fixed to the inside of the hermetically sealed container 50 for generating a linear moving force; a cylinder 80 fixed to the inside of the hermetically sealed container 50 adjacent to the outlet port 53; a discharging unit assembly 82 disposed in front of the outlet port 53 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com