Loading dock seal with flow through vent

a vent and dock seal technology, applied in the direction of roofs, loading/unloading, construction, etc., can solve the problems of high temperature in the loading area, heat can be very uncomfortable for workers loading and unloading goods, and the effect of increasing the visibility of the dock seal system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

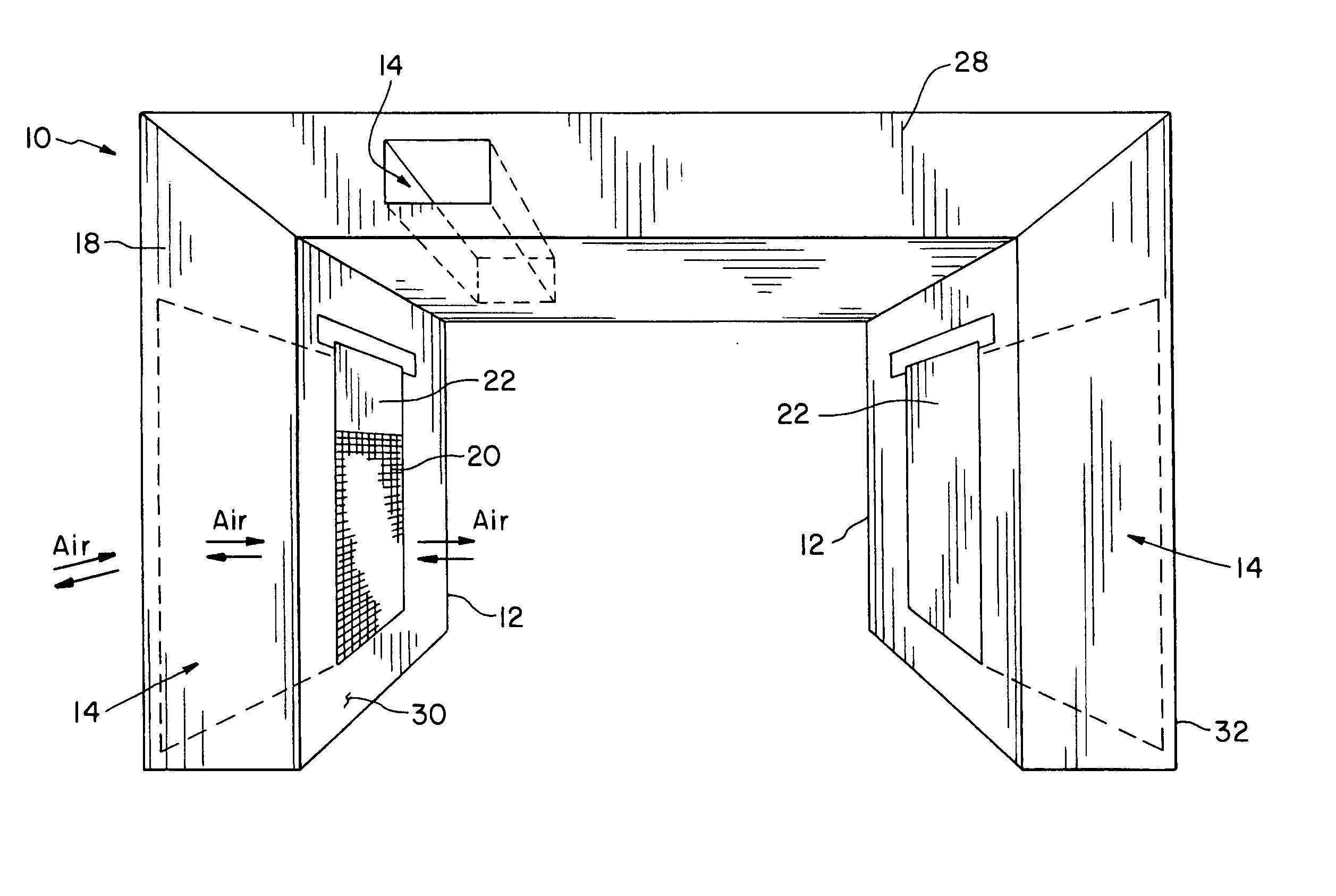

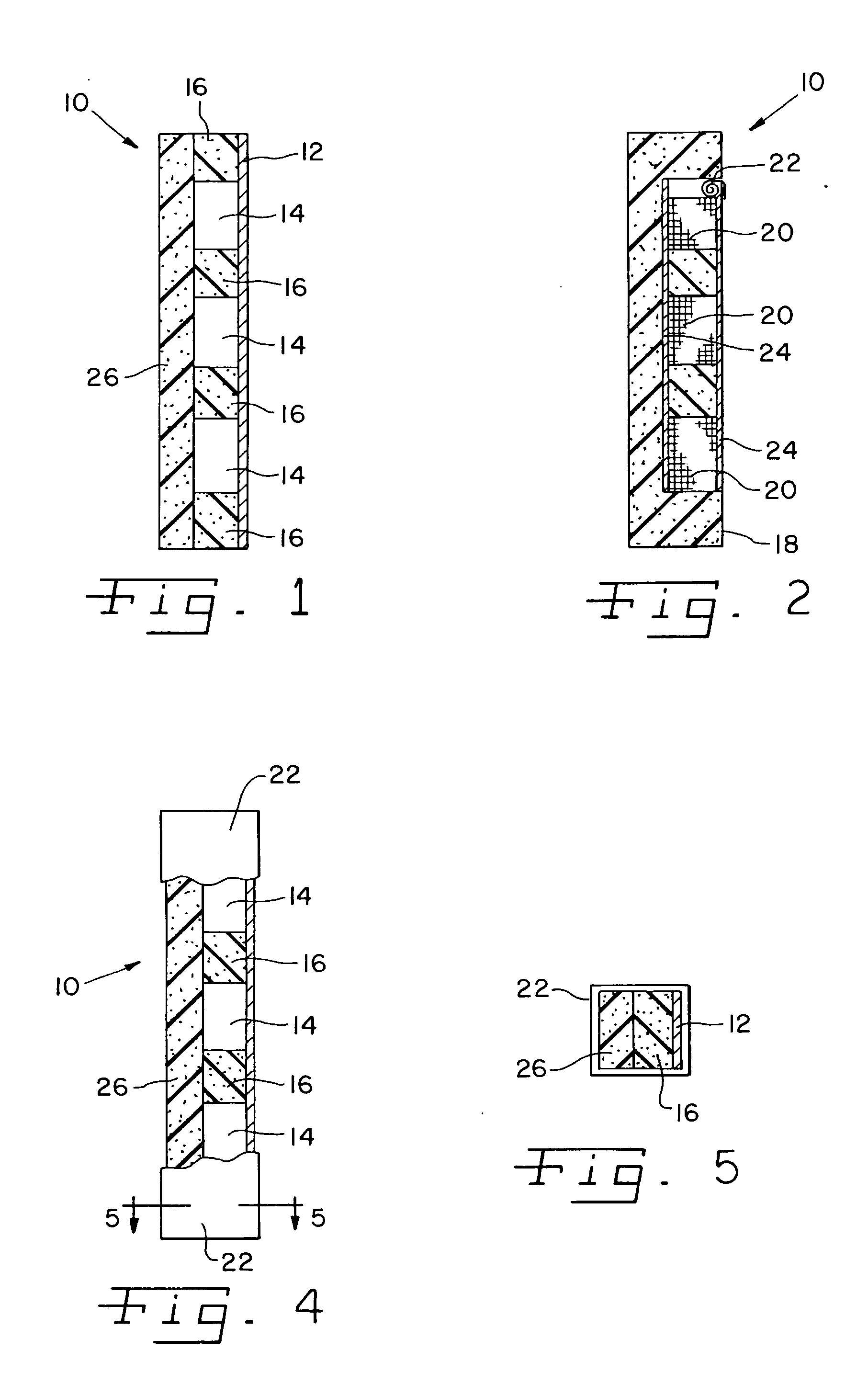

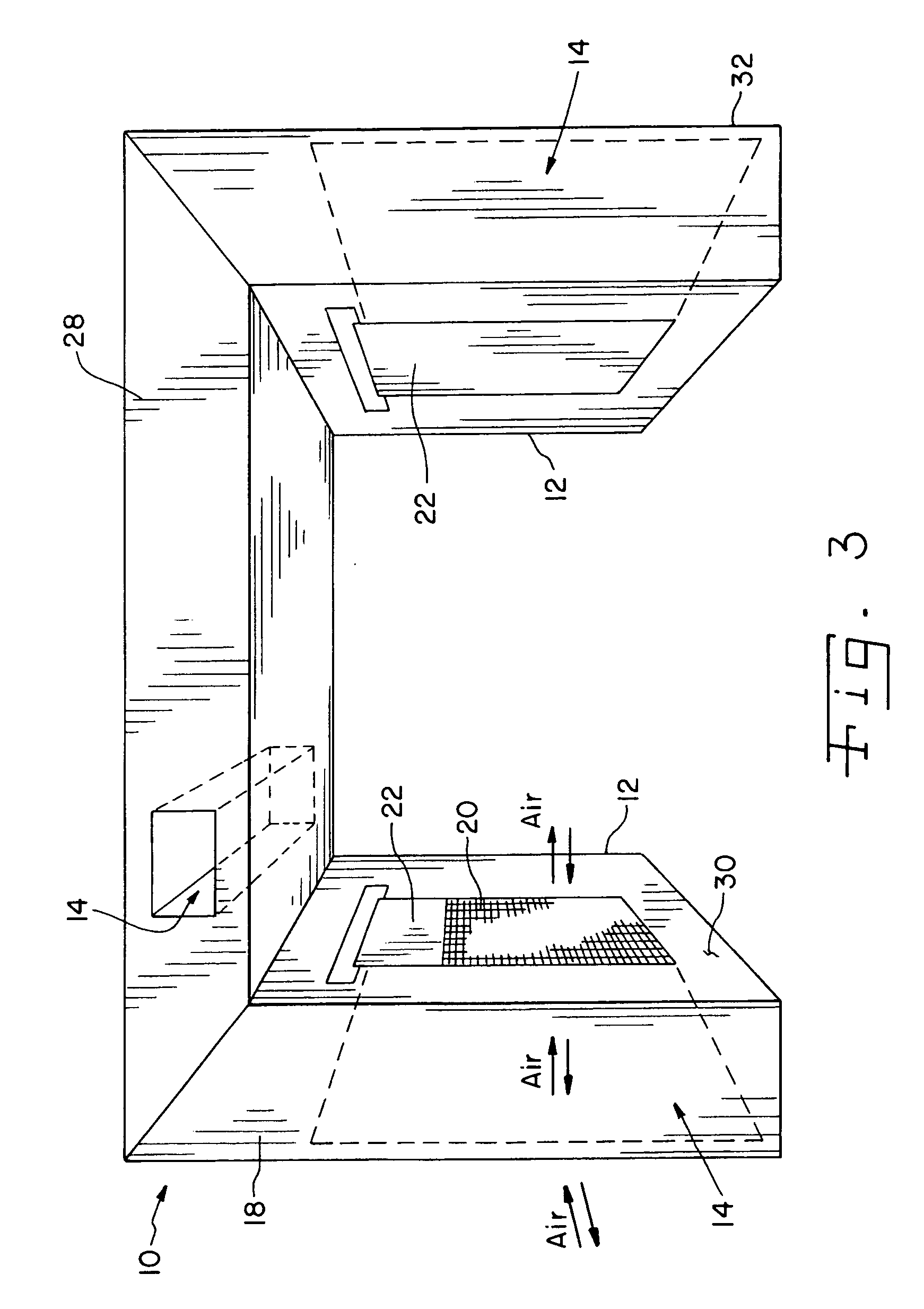

[0029] Referring now to the drawings and particularly to FIG. 1, there is shown one side of the loading dock seal system 10 of the present invention. Loading dock seal 10 has a base 12. Base 12 is constructed from wood, but other materials such as plastic or metal can be utilized therefor. Base 12 is approximately 2″×12″×8′ but other sizes thereof can be utilized as well. Base 12 is connected to a loading dock (not shown) utilizing bolts, fasteners, screws or any other type of connecting device (not shown).

[0030] One or more support members 16 are connected to base 12. Support members 16 are compressible pads made of a foam, rubber, or other elastomeric / resilient material. Support members 16 are connected to base 12 in preferably an evenly spaced apart relationship utilizing glue, bolts, screws, fasteners or other connecting devices. The present invention is not limited to support members 16 being spaced evenly apart but can be spaced at variable distances as well. Also, a single s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com