Muzzle loading firearm, gun barrel design, projectile system and method of using thereof

a projectile system and firearm technology, applied in the field of muzzle loading firearms, can solve the problems of degrading exposing the powder to the elements, and affecting the performance of the firearm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

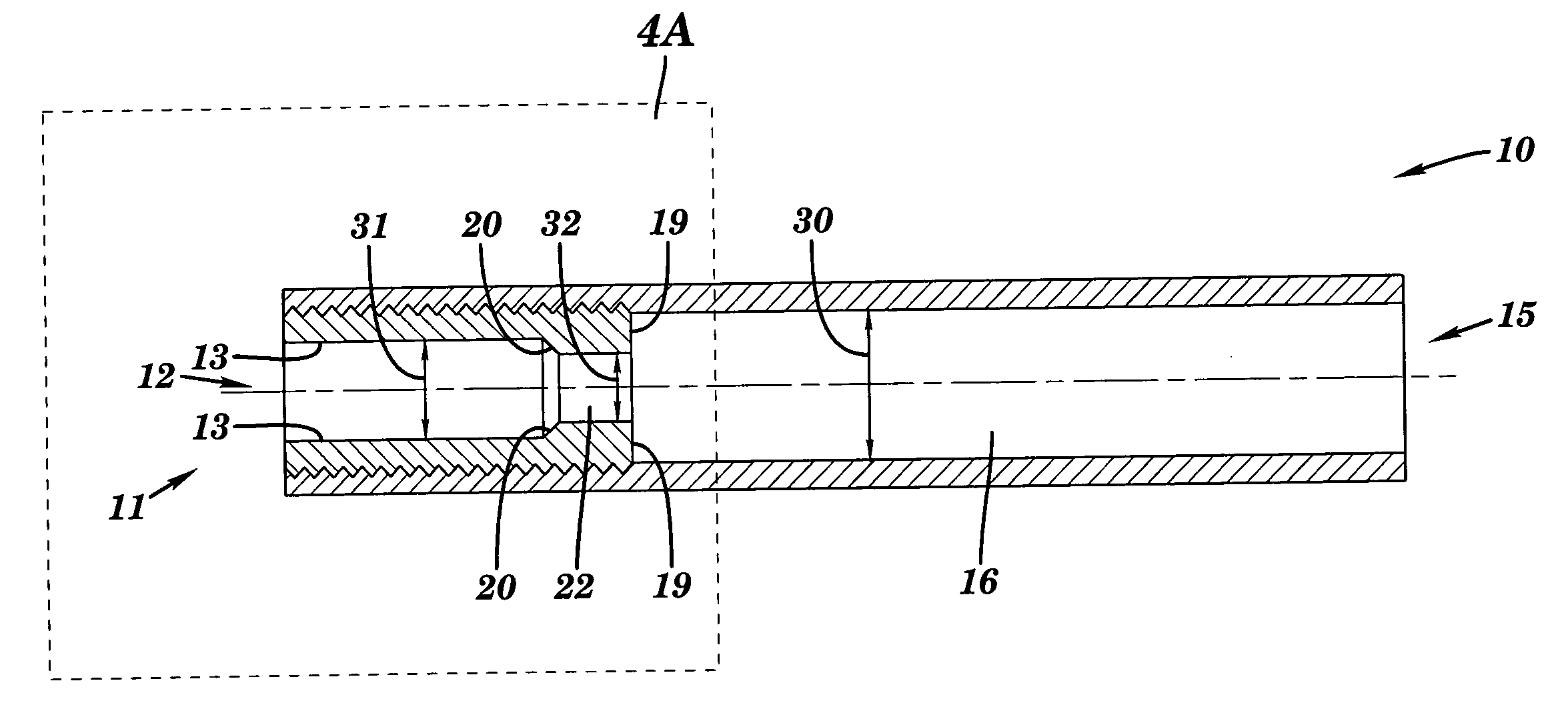

[0050] Although certain embodiments of the present invention will be shown and described in detail, it should be understood that various changes and modifications may be made without departing from the scope of the appended claims. The scope of the present invention will in no way be limited to the number of constituting components, the materials thereof, the shapes thereof, the relative arrangement thereof, etc., and are disclosed simply as an example of an embodiment. The features and advantages of the present invention are illustrated in detail in the accompanying drawings, wherein like reference numerals refer to like elements throughout the drawings.

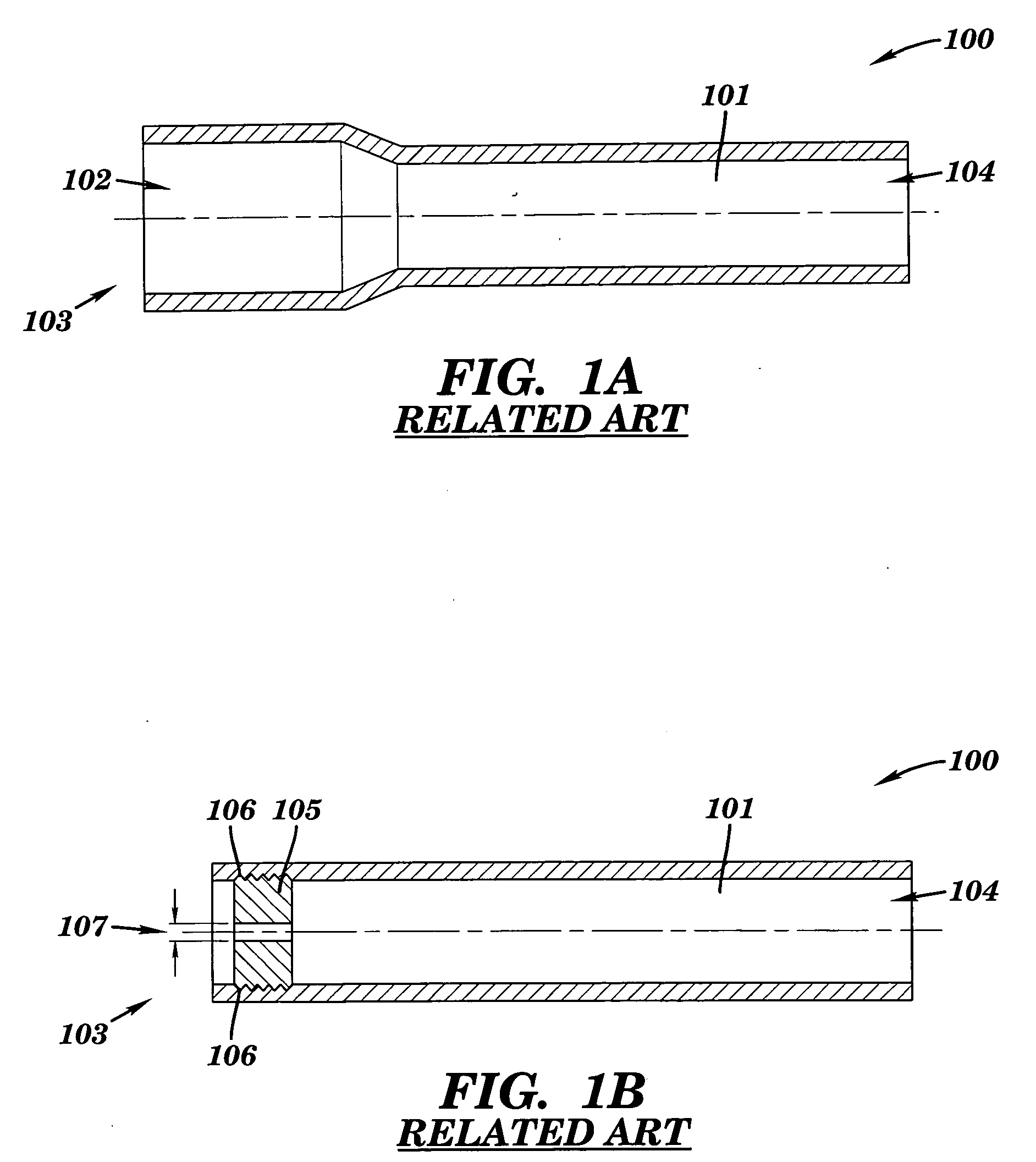

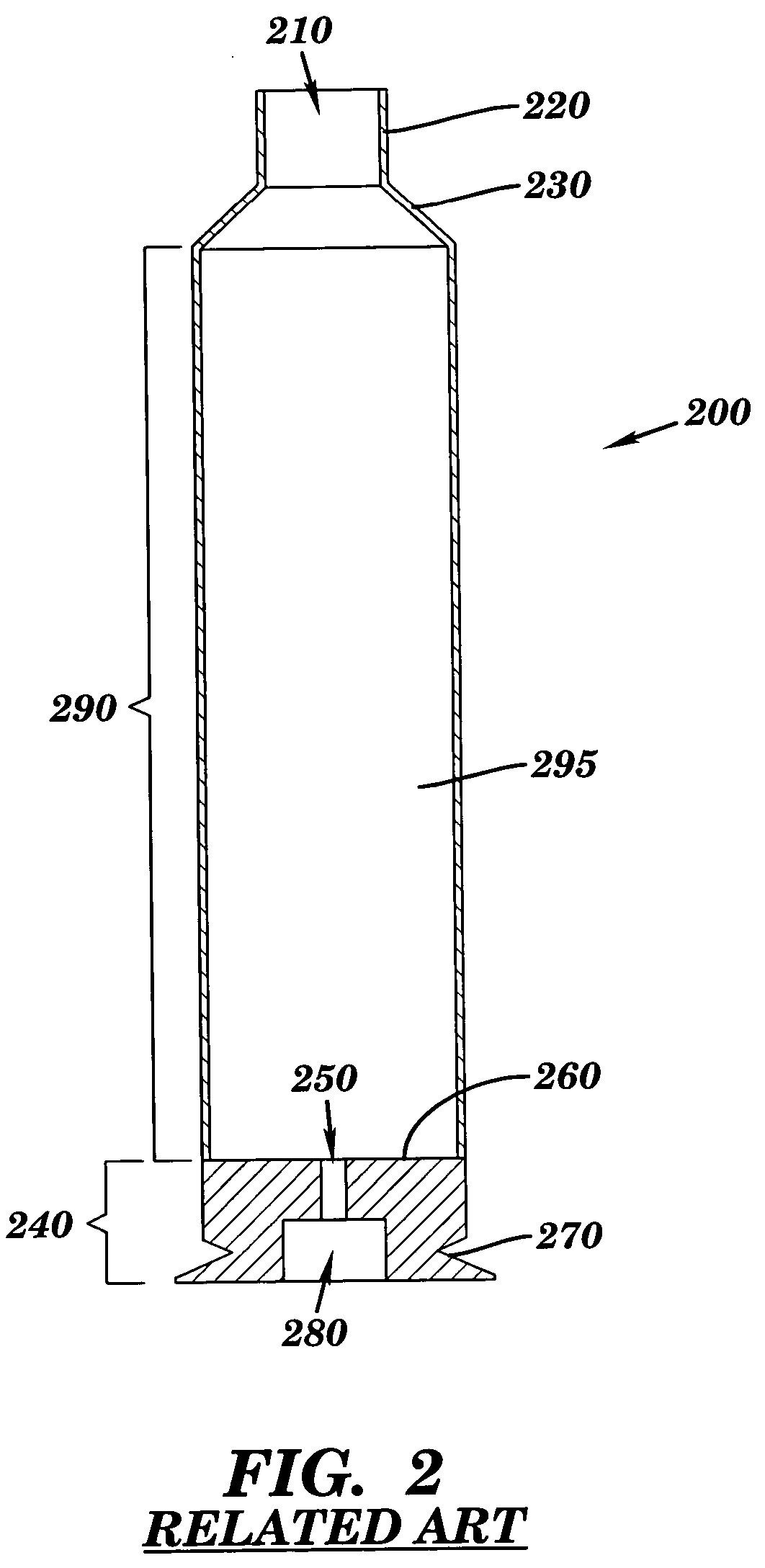

[0051] Referring to the drawings, and Figures IA and 1 B, in particular, which depict side sectional views of typical gun barrel with loading chambers known in the art. Both FIGS. 1A and 1B depict a gun barrel 100 with a muzzle end 104 and at the distal end, a breech end 103. Both gun barrels 100 have a bore 101.

[0052]FIG. 1A show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com