Coolant tray of liquid based cooling device

a cooling device and liquid based technology, applied in the field of cooling devices, can solve the problems of limited heat removal of aluminum extrusion heat sinks, complicated assembly of cooling devices, and large volume of cooling devices, and achieve the effects of reducing overall size, reducing structure and manufacturing of cooling devices, and limited interior spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

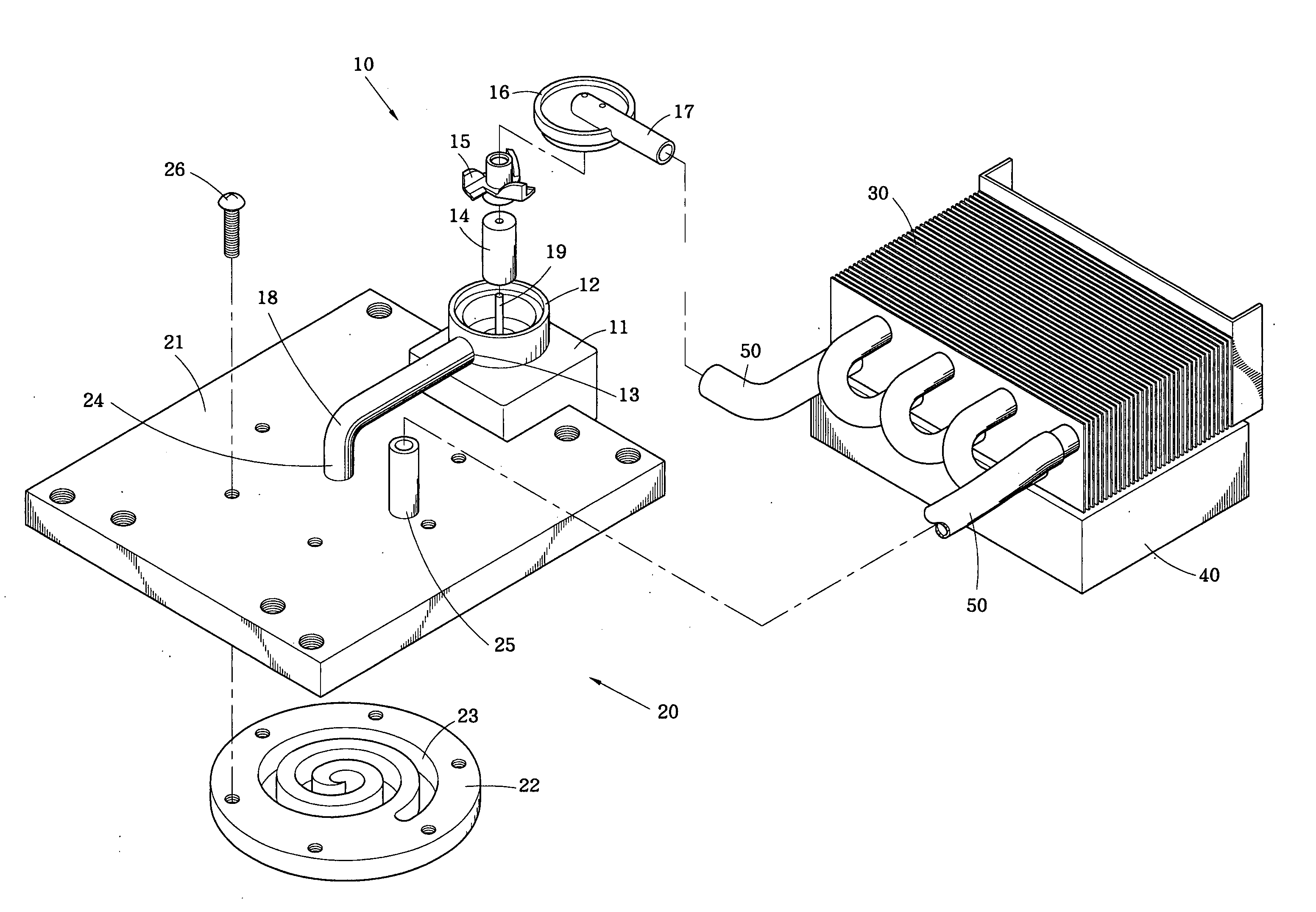

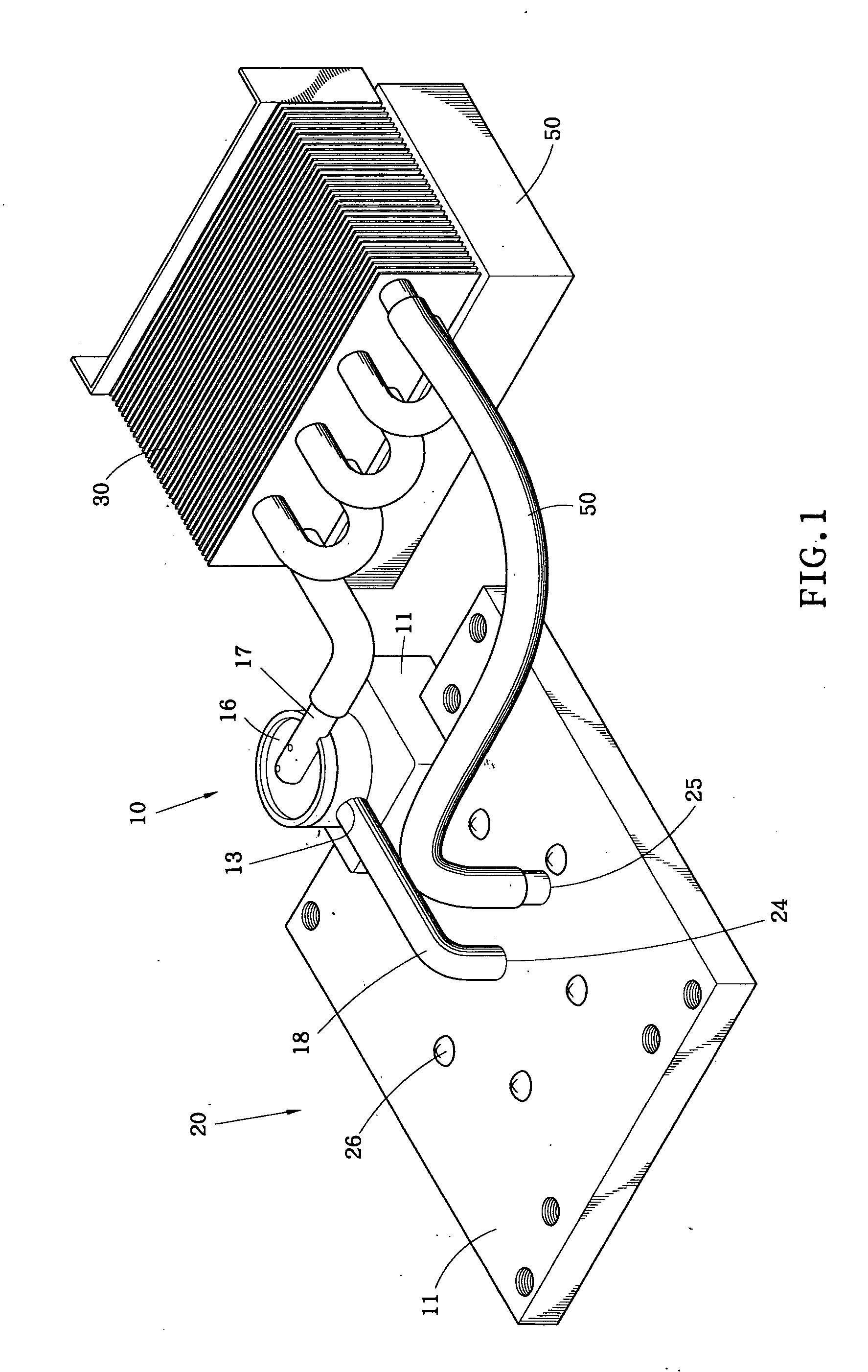

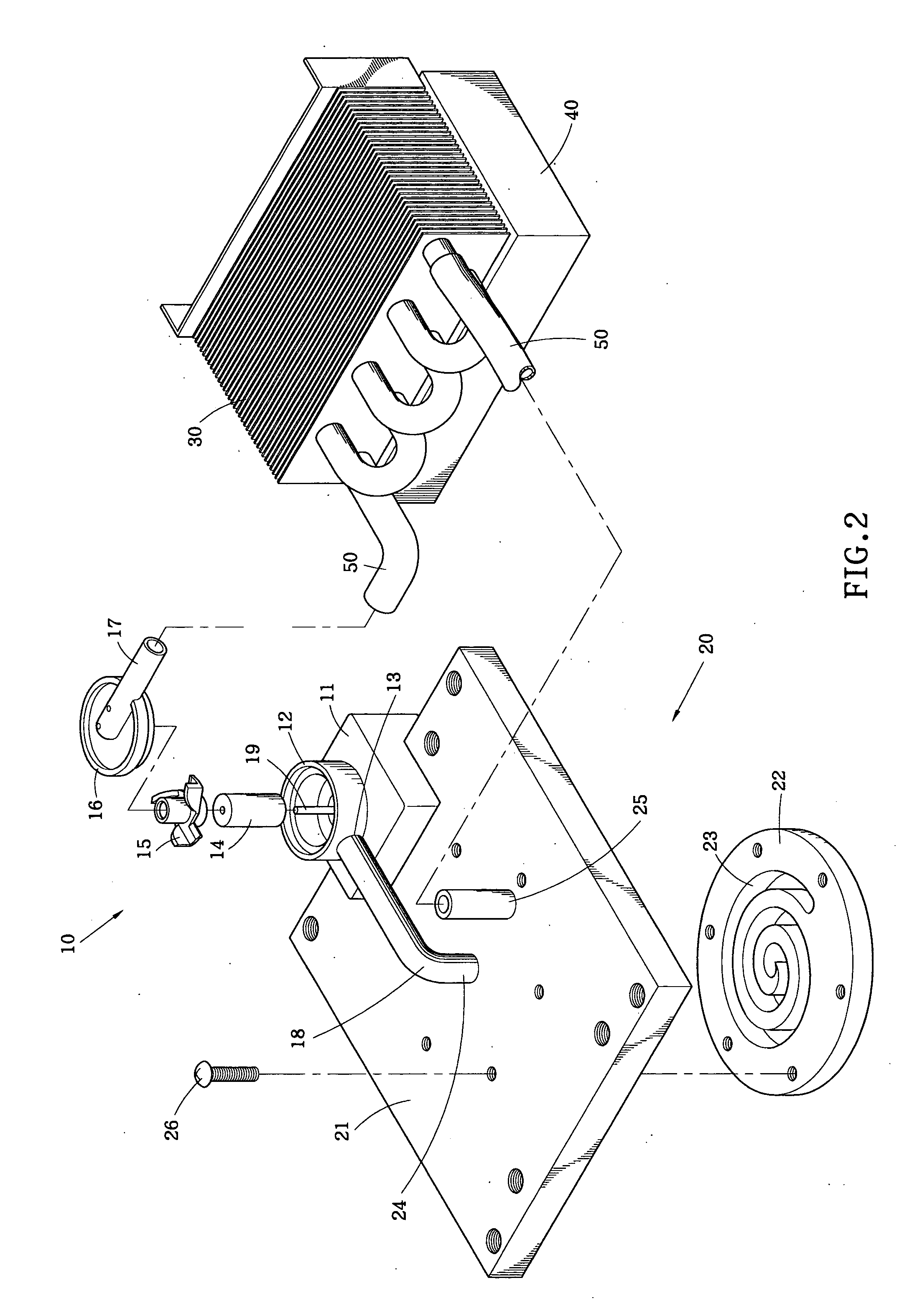

[0016] With reference to the drawings and in particular to FIG. 1, a liquid based cooling device is shown. The cooling device is operated with a liquid coolant, such as water, for cooling for example an electronic device 29, such as a computer central processing unit mounted on a circuit board 28 of the computer system (see FIG. 3), which generates heat that must be removed to maintain the temperature of the electronic device 29 within a proper range. The cooling device is comprised of a coolant tray 20 having a surface positionable on and in physical contact with the electronic device 29, a radiator 30 spaced from the coolant tray 20 and located in a low temperature surrounding, and a pump 10 connected to the radiator 30 and the coolant tray 20 by pipes to complete a circulation loop among the coolant tray 20, the pump 10, and the radiator 30. The pump 10 circulates a coolant between the coolant tray 20 and the radiator 30. Heat carried by the coolant to the radiator 30 is dissipat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com