Stoker grates for circulating burning-up

a technology of circulating burning up and stoker, which is applied in the direction of grates, combustion process, lighting and heating apparatus, etc., can solve the problems of large coal loss and incomplete combustion, and achieve the effect of remarkable improvement of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

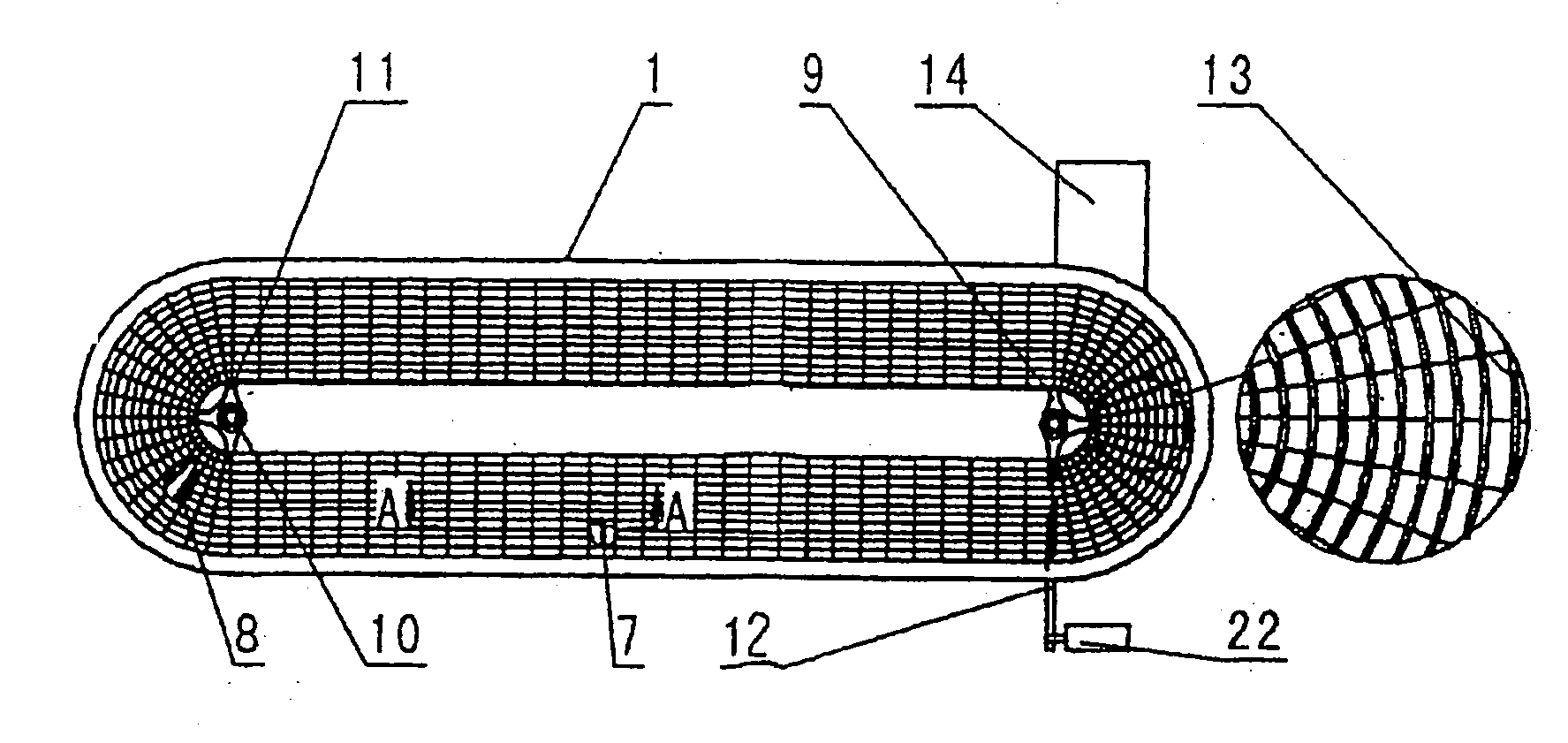

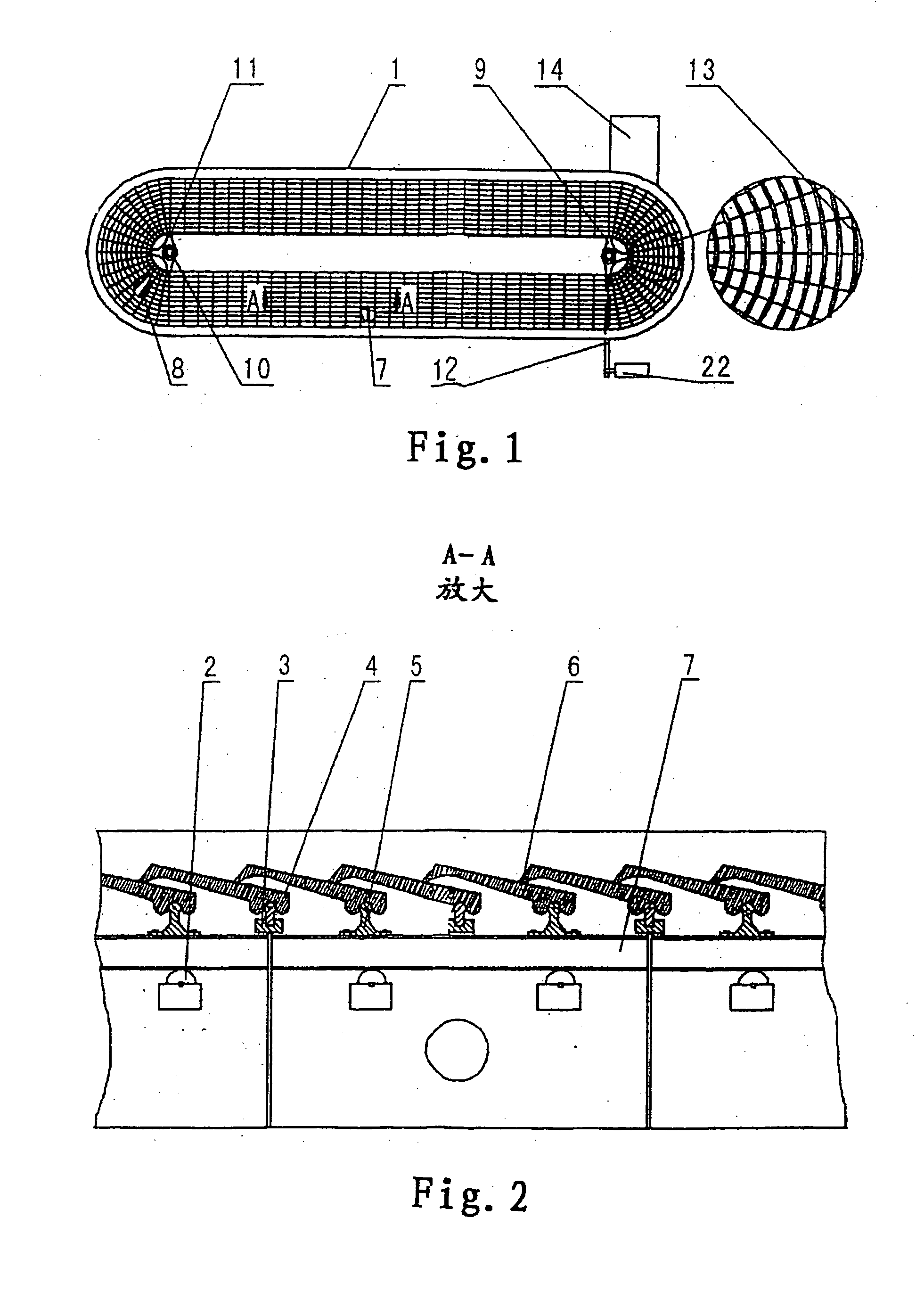

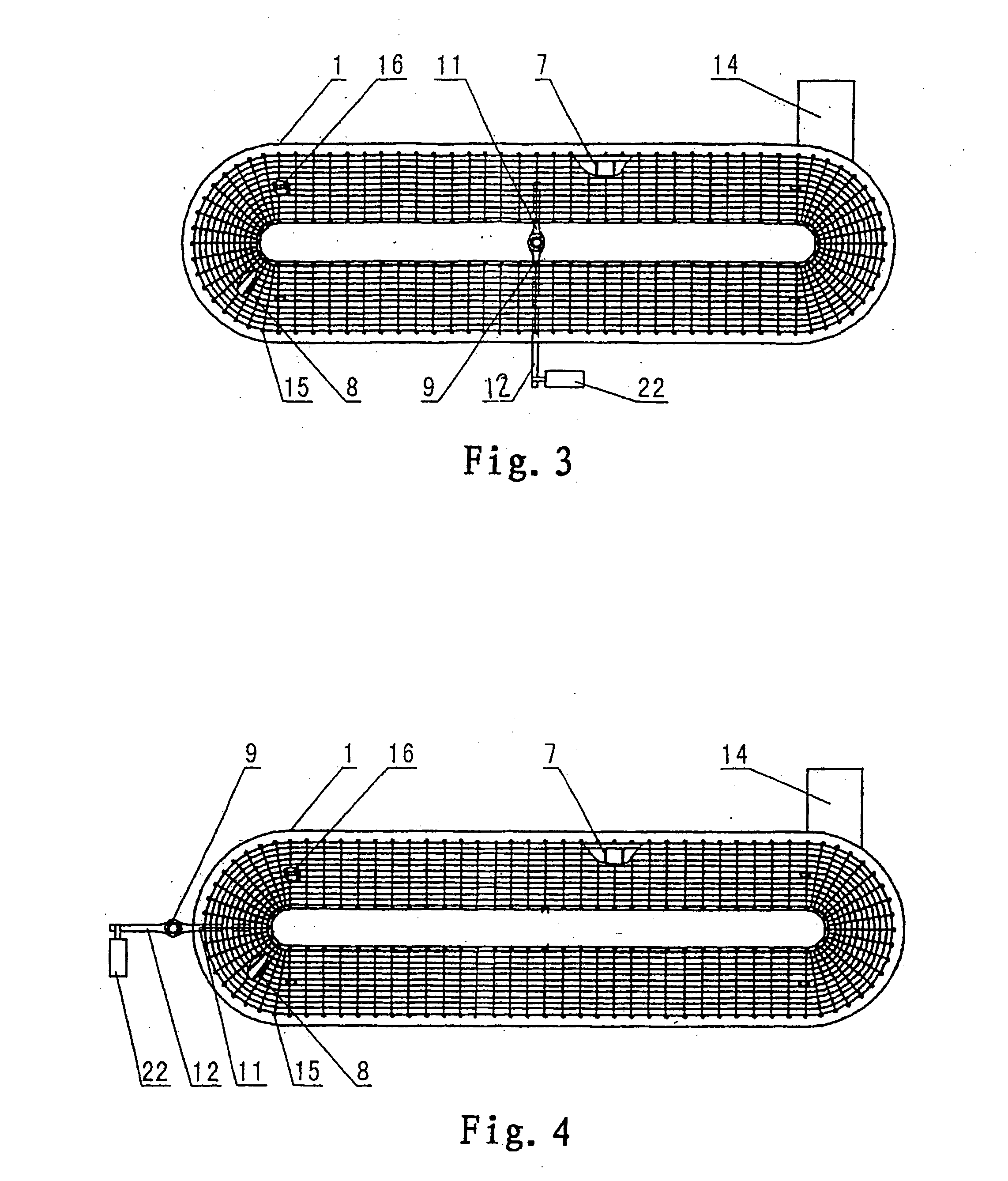

[0017] Hereinafter, the preferred embodiments of the invention will be described with reference to the drawings. In an embodiment shown as in FIGS. 1 and 2, the grate comprises a stationary grate sheet support 1, moveable grate sheet supports fitting with prop rolls 2 on the stationary grate sheet support 1, the stationary grate sheets 4 fitting with mounting transverse beams 3 of the stationary grate sheet support 1, moveable grate sheets 6 fitting with mounting transverse beams 5 of the moveable grate sheet support, and a transmission unit, wherein the moveable grate sheets 6 and the stationary grate sheets 4 are disposed alternatively, the stationary grate sheet support 1 has a long annular shape, the moveable grate sheet supports comprise a pair of rectangular moveable grate sheet supports 7 opposed to each other and another pair of semi-annular moveable grate sheet supports 8 opposed to each other to form a long annular shape assembled support, the transmission unit is two sets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com