Motorcycle fork bottom which is stiffer front-to-back than side-to-side

a technology of front suspension and fork bottom, which is applied in the direction of friction roller based transmission, steering device, cycle equipment, etc., can solve the problems of stiffness of fork bottom, unfortunate side effect, and reduced effectiveness of front suspension of motorcycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

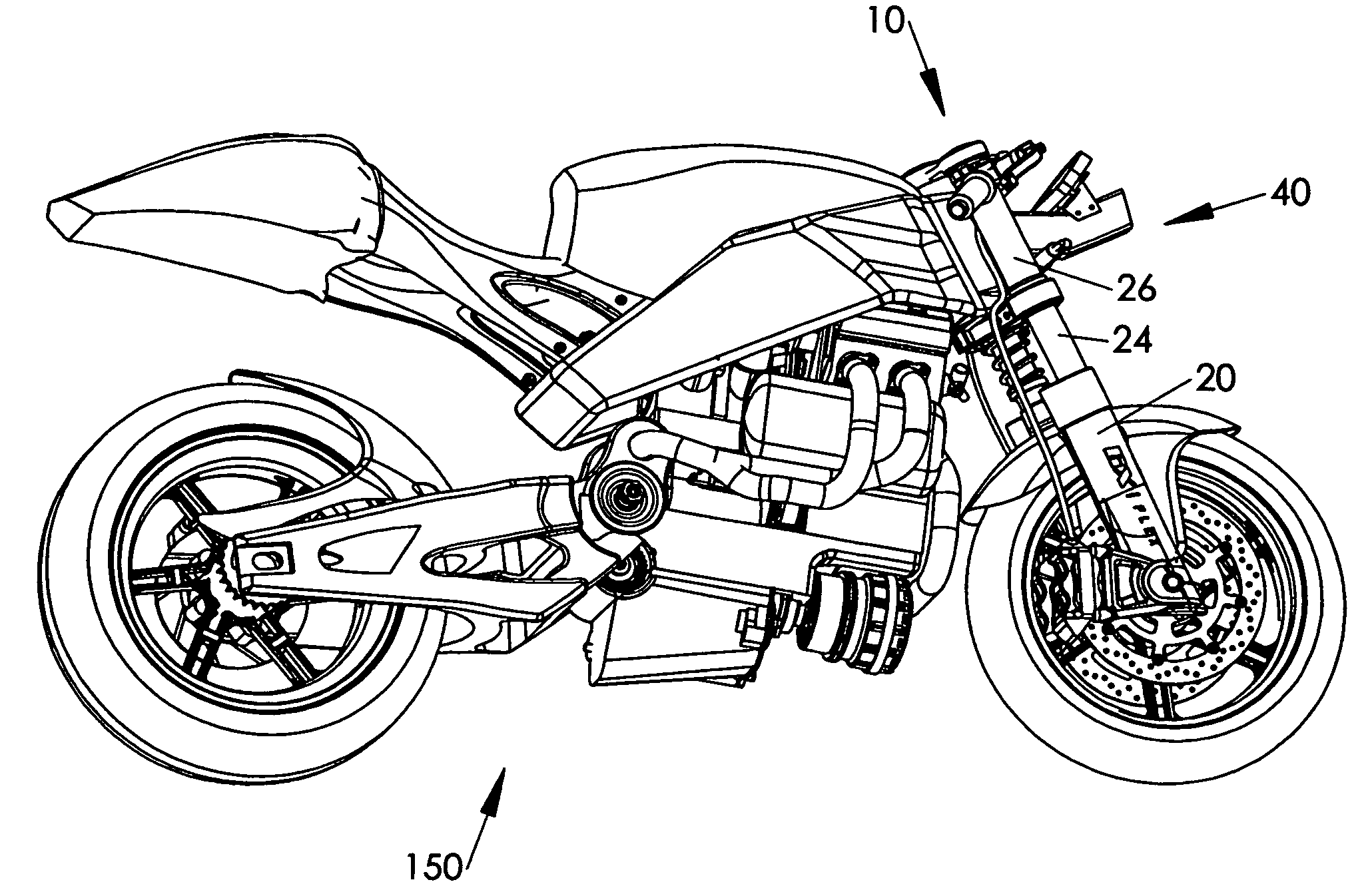

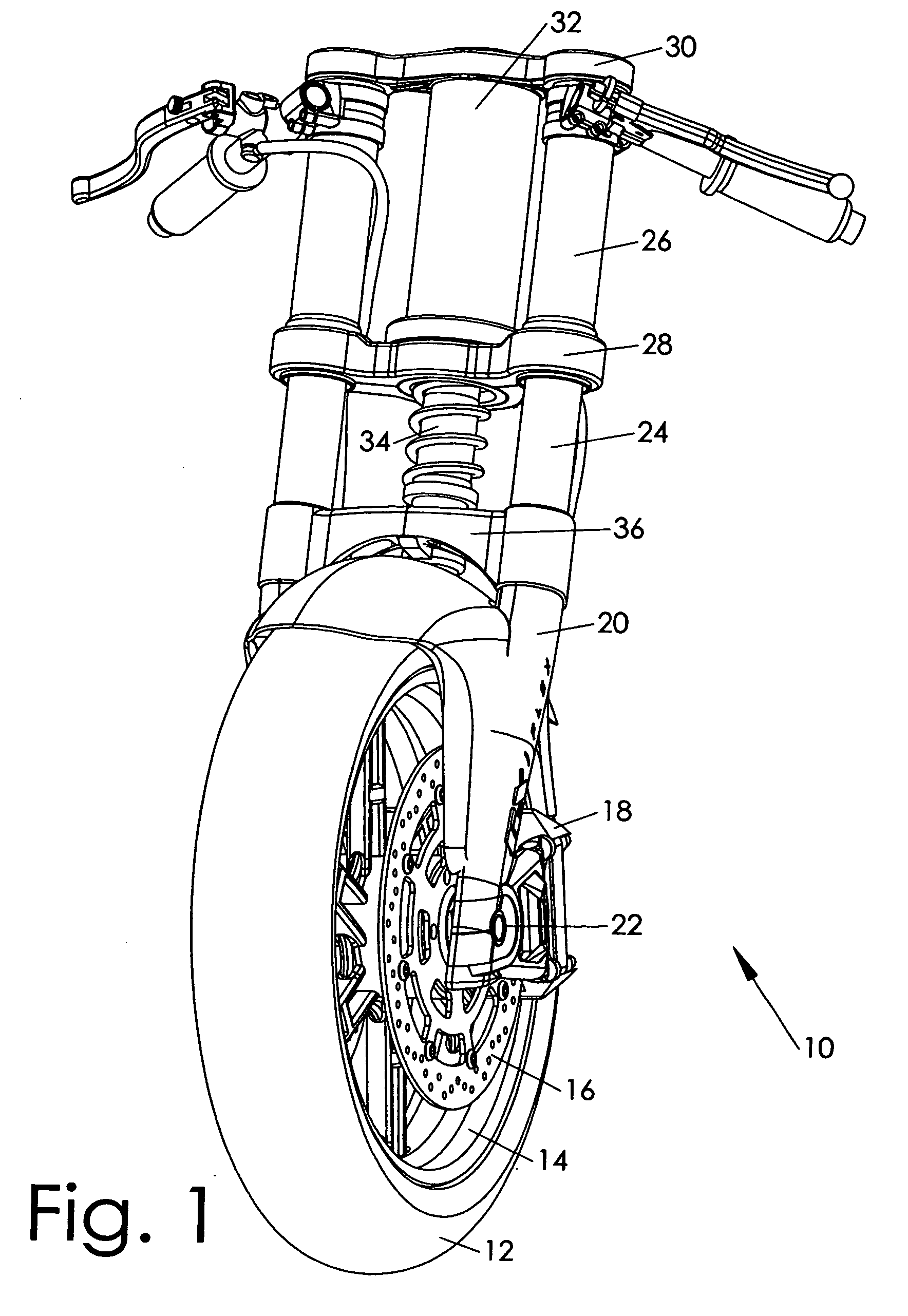

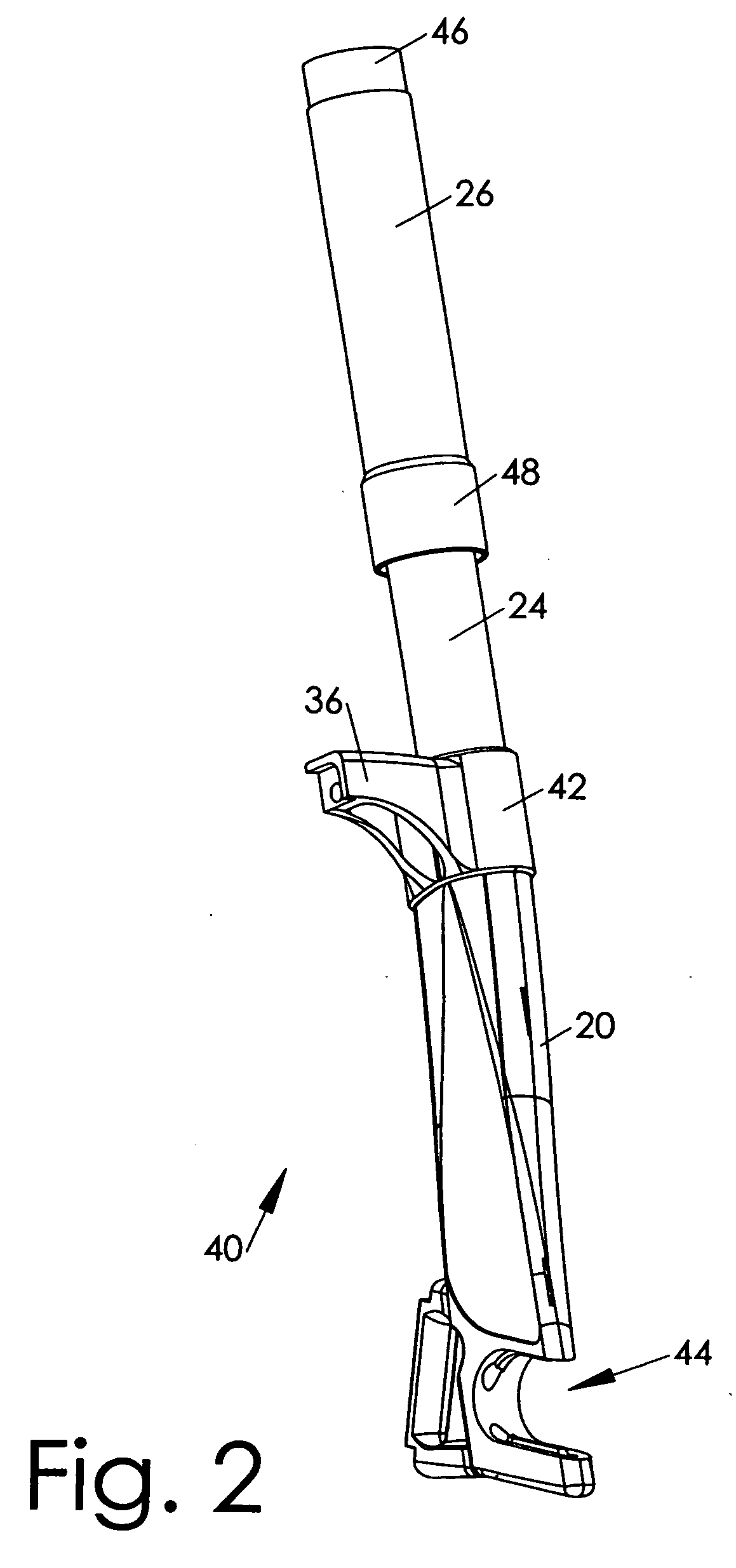

[0018]FIG. 1 illustrates one embodiment of a motorcycle front end 10, viewed generally from the front. The front end includes a tire 12 mounted on a wheel 14 and equipped with brake rotors 16 and brake calipers 18. A fork bottom 20 includes a fork bottom body coupled to the axle 22 and to a pair of male lower fork tubes 24 which slide in a pair of female upper fork tubes 26. The longitudinal (in the direction of travel) stiffness of the fork bottom is different than the lateral (side-to-side) stiffness of the fork bottom. In one embodiment, the longitudinal stiffness is greater than the lateral stiffness. In some embodiments, the lateral stiffness of the fork bottom is adjustable, as explained below.

[0019] A lower triple clamp 28 and an upper triple clamp 30 are coupled to the upper fork tubes and couple them to a steering stem assembly (not visible) which rotates within a steering tube 32 which is part of, or coupled to, the frame (not shown) of the motorcycle.

[0020] The front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com