Sealer tape and clip assembly

a technology of adhesive tape and assembly, which is applied in the direction of roofs, transportation and packaging, vehicle arrangements, etc., can solve the problems of disadvantageous two-step process of prior art adhesive tape assemblies, and achieve the effect of reducing the cost of adhesive tape assemblies and advantageous installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

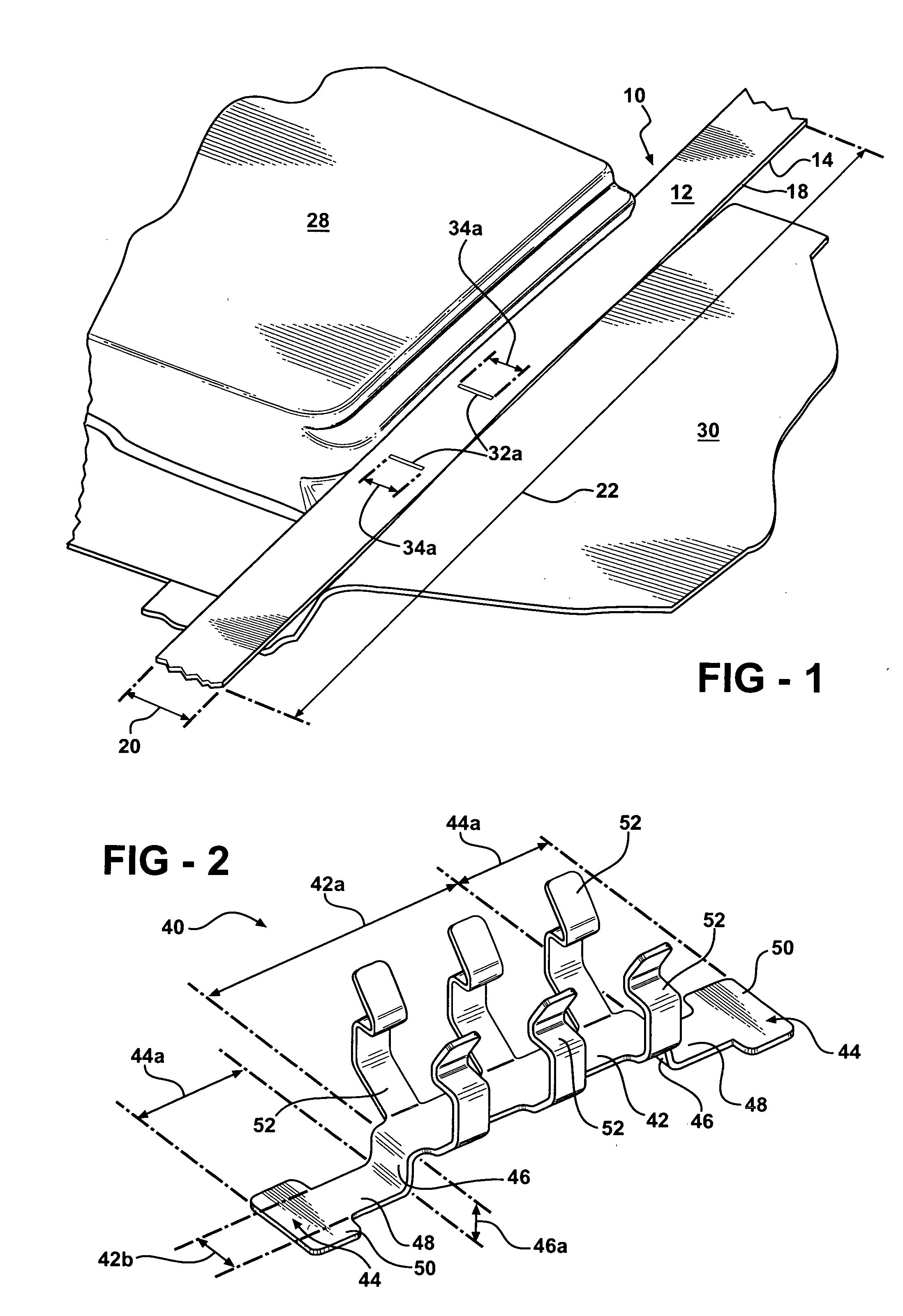

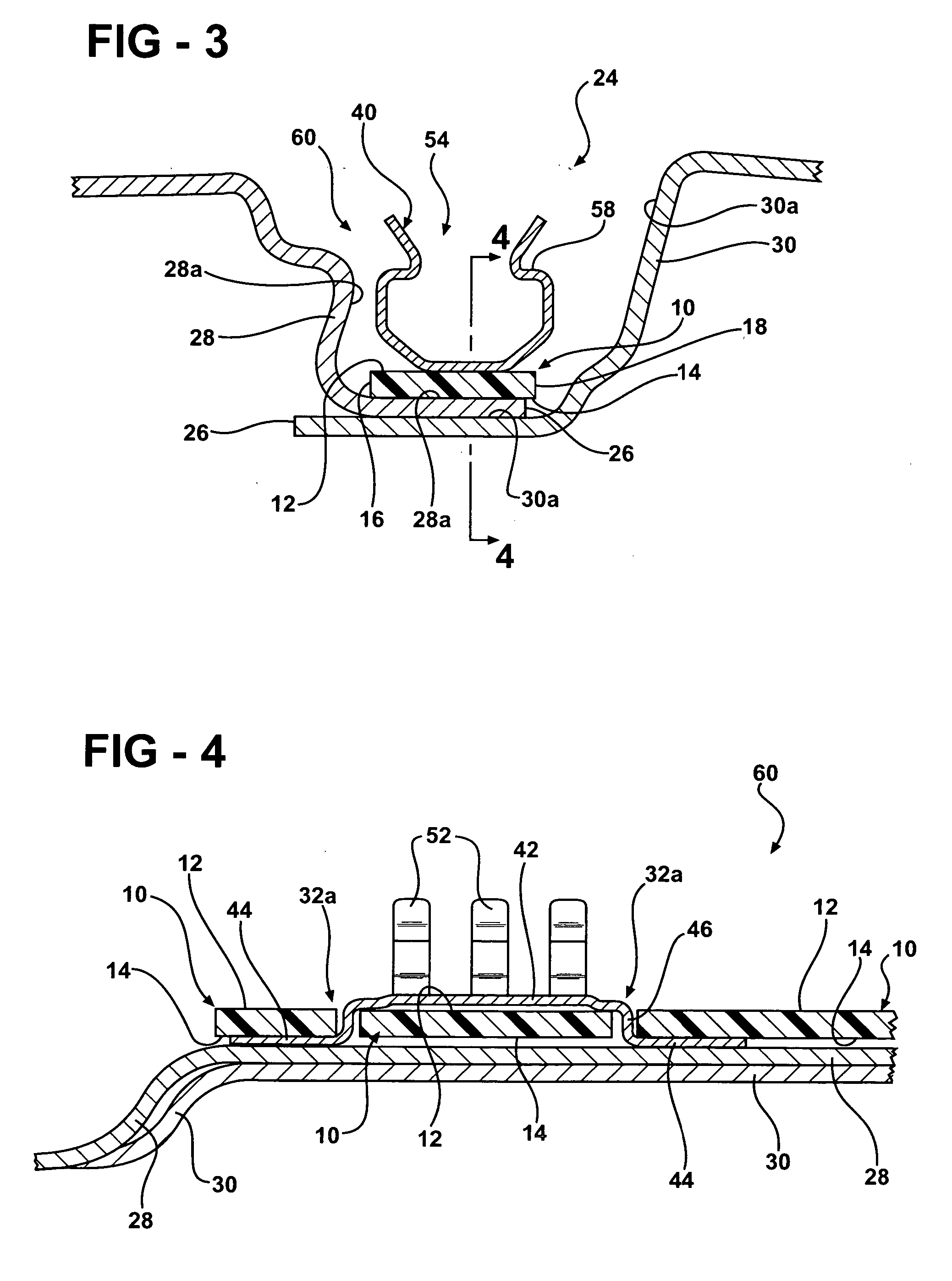

[0015] Referring now to the first embodiment shown in FIGS. 1-4, a sealer tape member in accordance with the present invention is indicated generally at 10. The sealer tape member 10 includes an upper surface 12, a lower surface 14, and opposed side surfaces 16 and 18. The sealer tape member 10 is preferably constructed of a polymer or co-polymer material, such as ethylene vinyl acetate co-polymer, or a similar type material. The sealer tape member 10 has a width indicated by an arrow 20 and a length indicated by an arrow 22. The length 22 of the sealer tape member 10 is significantly greater than the width 20 of the sealer tape member 10. The sealer tape member 10 is adapted to be disposed in a recess 24, best seen in FIG. 3, extending along joined edges 26 of a first body panel 28 and a second body panel 30. Preferably, the body panels 28 and 30 are vehicle body panels, such as a vehicle body panel and a vehicle roof panel having the recess 24 formed therebetween. The recess 24 is...

second embodiment

[0020] Referring now to the second embodiment shown in FIGS. 5-7, the sealer tape member 10 includes an aperture 32b formed therein that extends through the upper surface 12 and the lower surface 14. The aperture 32b is disposed between but does not extend through the opposed side surfaces 16 and 18 of the sealer tape member 10. The aperture 32b has a length indicated by an arrow 34b and a width (not shown). The length 34b of the aperture 32b is greater than the width of the aperture 32b, and the length 34b of the aperture 32b extends substantially parallel to the length 22 of the tape member 10 and substantially perpendicular to the width 20 of the tape member 10.

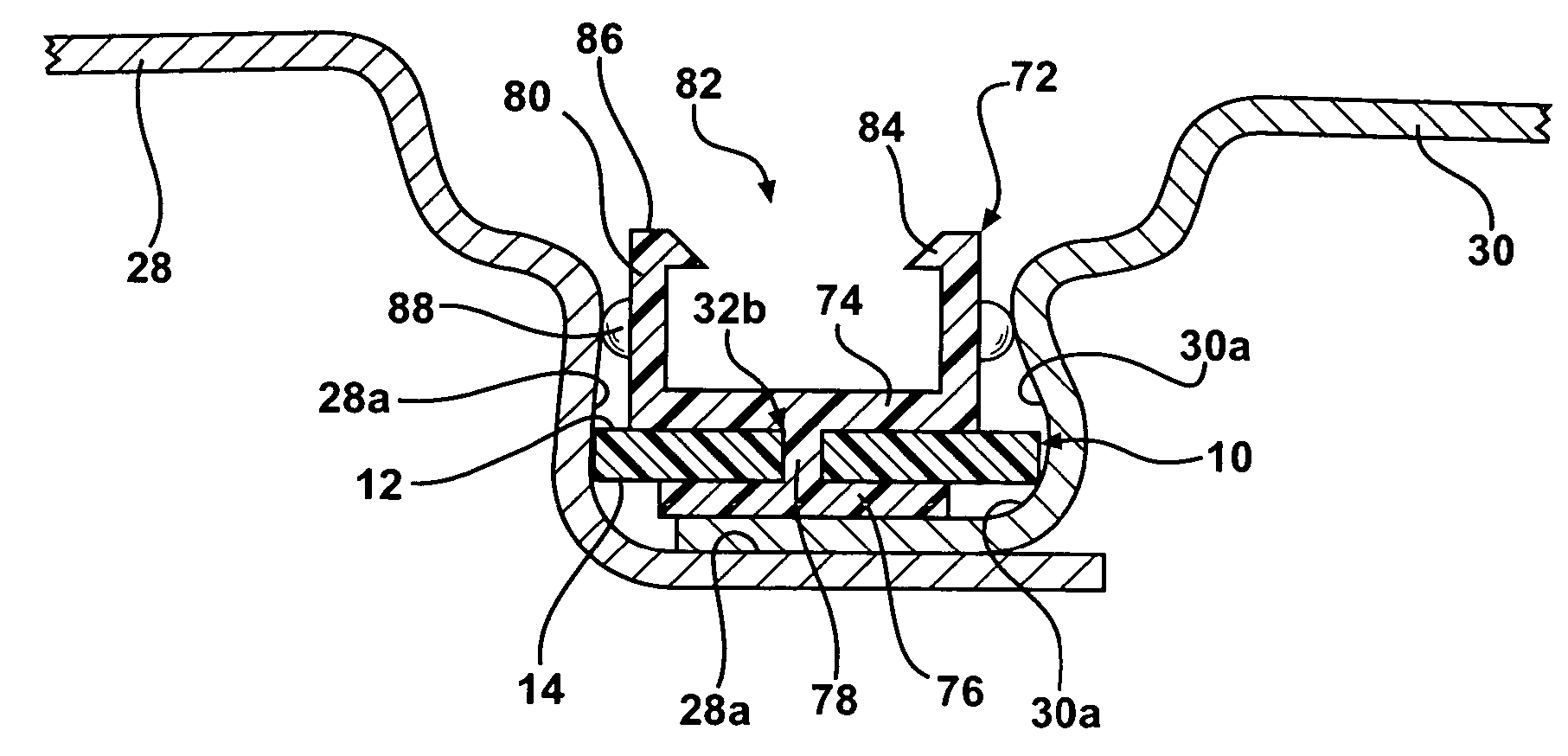

[0021] An alternative embodiment of a sealer tape and clip body assembly in accordance with the present invention is indicated generally at 70. The assembly 70 includes a clip body 72 having an elongated, generally rectangular and substantially planar upper portion 74 having a length indicated by an arrow 74a, and an elong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com