Dielectric optical fibre cable with improved mounting characteristic

A cable and optical fiber technology, applied in the field of dielectric optical fiber cables, can solve problems such as performance degradation and low installation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

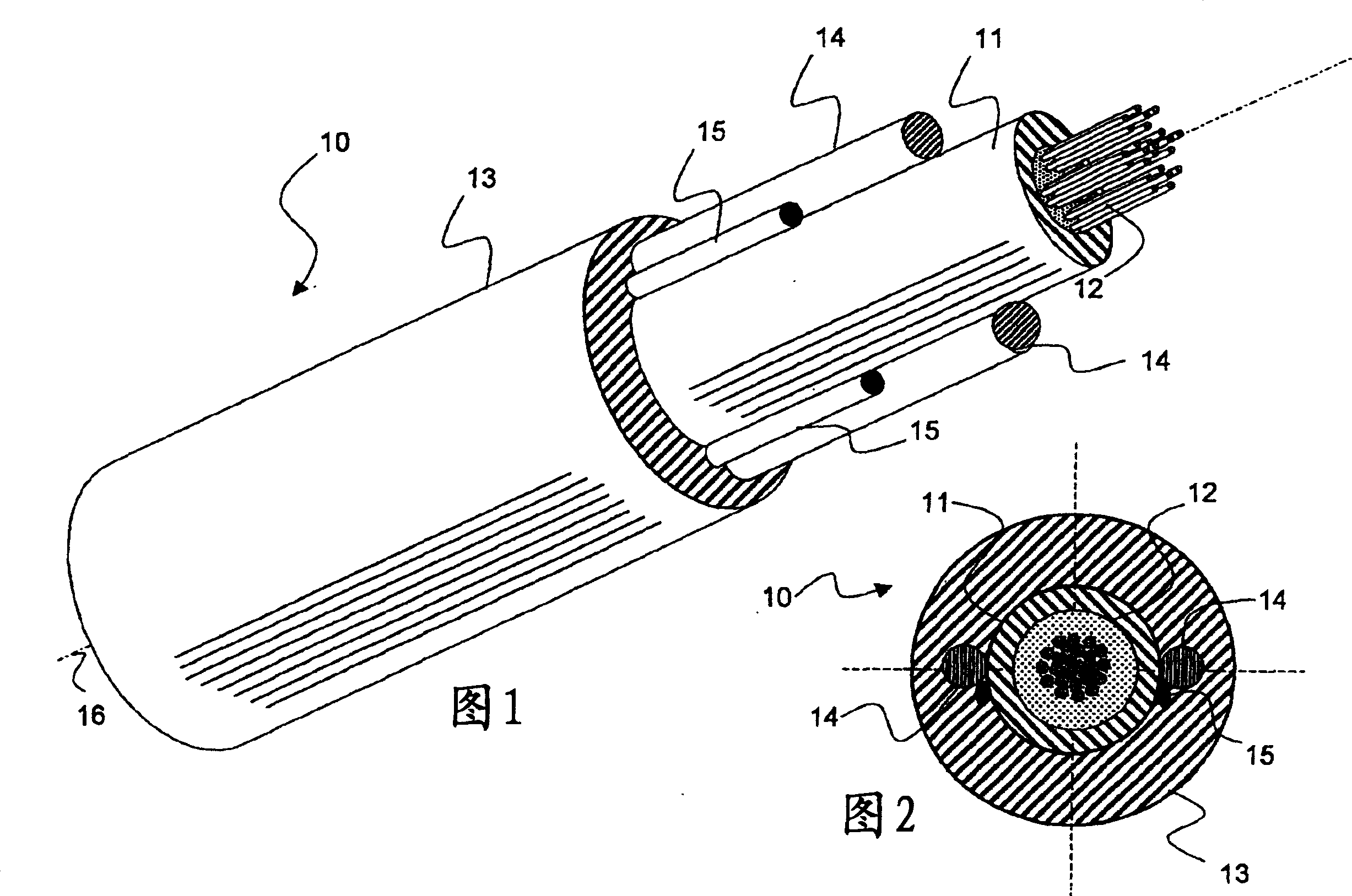

[0044] 1 and 2, a dielectric fiber optic cable 10 according to the present invention at least includes: a core sleeve 11 containing an optical fiber 12, a plastic sheath 13 surrounding the core sleeve 11, a pair of straight lines at least partially embedded in the sheath 13 extended, diametrically opposed dielectric rods 14, wherein the rods 14 have a compressive stiffness effective to resist substantial contraction of the cable, and effective to receive tensile loads without substantial transfer of the tensile loads to the optical fiber 12 of tensile stiffness. The cable according to the invention may also comprise a sheath cutting element 15 for cutting the sheath 13 at the end of the cable for easy access to the optical fibers. The cable 10 has a longitudinal axis 16 .

[0045] Preferably, said rods comprise filamentous strands of glass and / or aramid fibres, more preferably they are made of GRP (glass reinforced plastic) or ARP (aramid reinforced plastic). Furthermore, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com