Electromagnetically-actuated microfluidic flow regulators and related applications

a flow regulator and microfluidic technology, applied in the direction of piston pumps, positive displacement liquid engines, instruments, etc., can solve the problems of high power consumption, complex automated drug-dosing regimens can be programmed, and high cost of fabrication, so as to optimize the operation and minimize power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

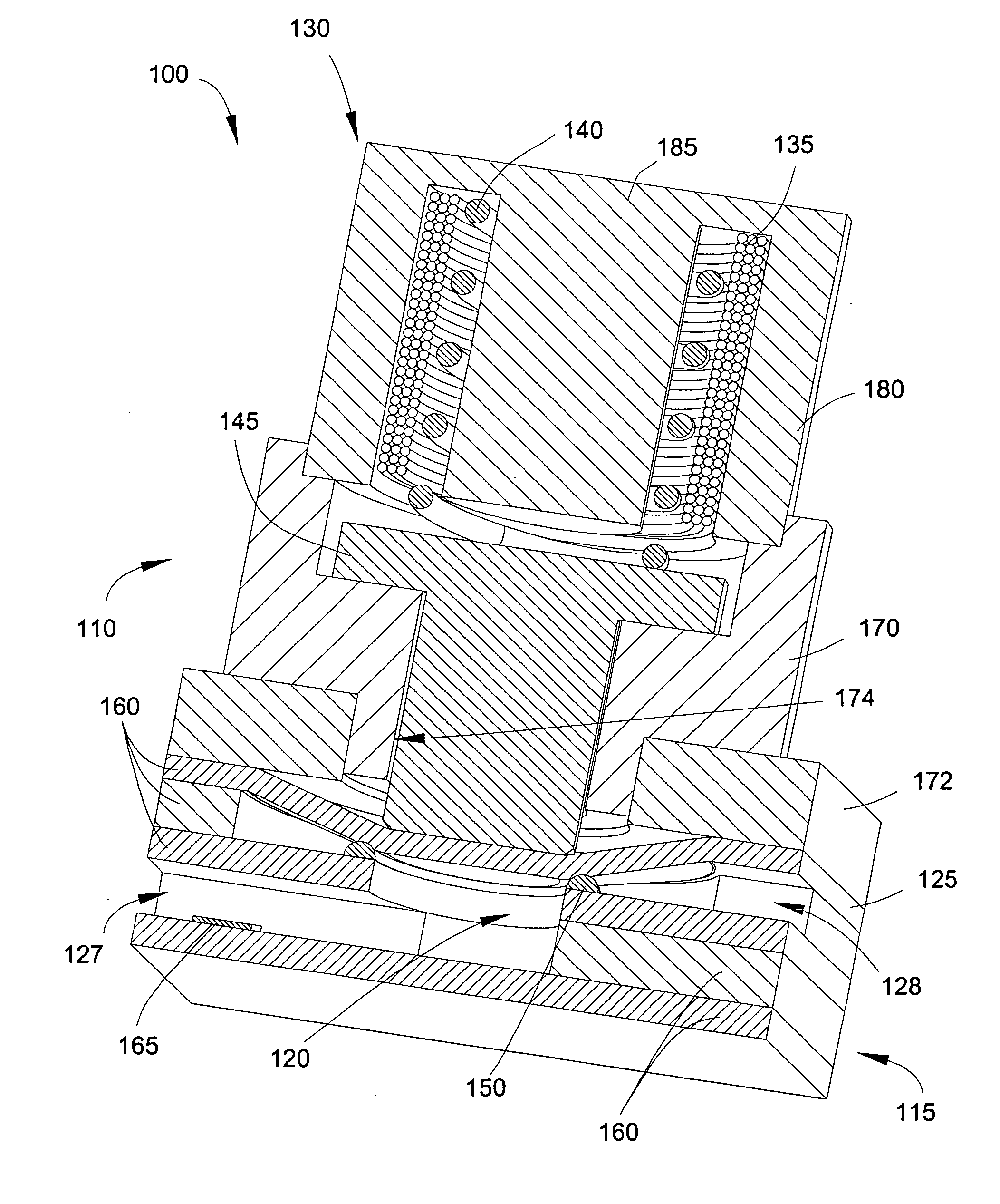

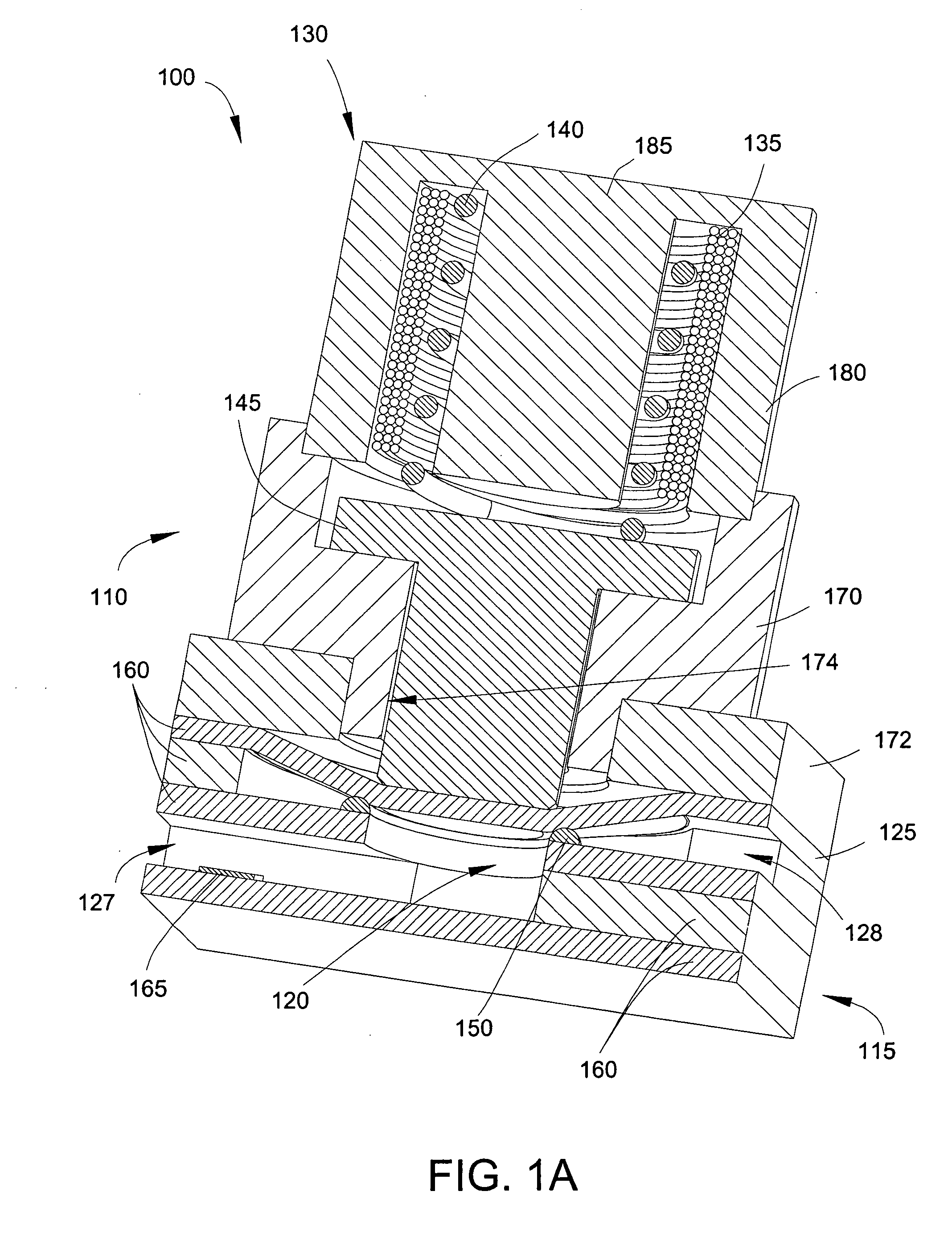

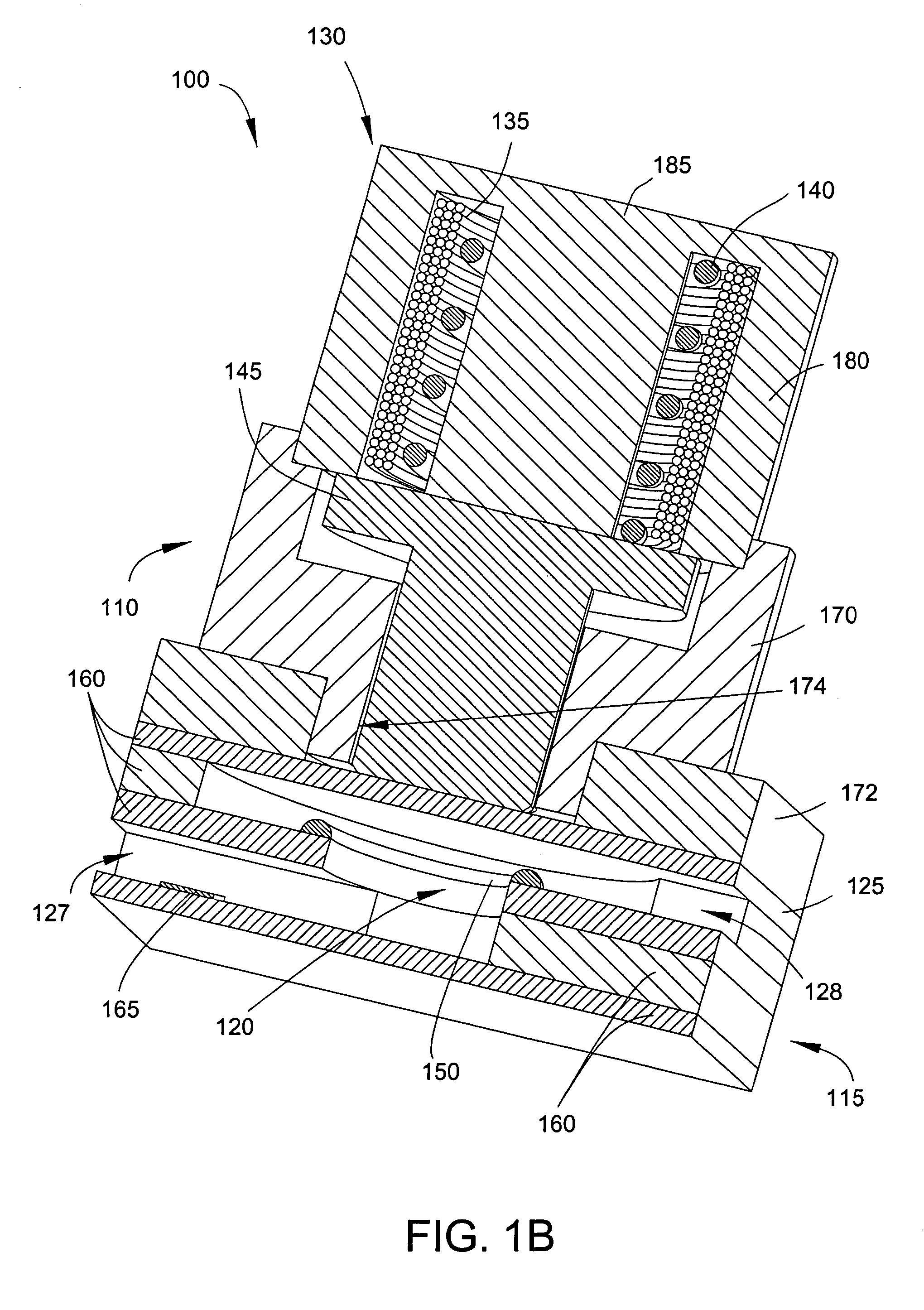

[0045] As mentioned above, various aspects of the invention contemplate a variable, closed-loop apparatus for regulating a microfluidic flow employing a tow-power deflection assembly, which is surface-mounted over a flexible membrane that overlies a chamber integrated into a substrate, thereby allowing for modular flexibility and rapid prototyping. In various embodiments, to minimize power consumption and optimize the operation, the apparatus relies on magnetic force for deflection of the membrane towards either forward or retracted position thereof. White generally described in conjunction with a microfabricated substrate, various aspects of the invention may employ a substrate fabricated using known precision non-microscale methods of manufacturing printed circuit boards.

[0046] Referring to FIGS. 1A-1B, in various embodiments, an apparatus 100 for regulating a microfluidic flow includes an electromagnetically-driven assembly 110 fabricated by conventional machining techniques and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com