Rotating, explosive sub-calibrated projectile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

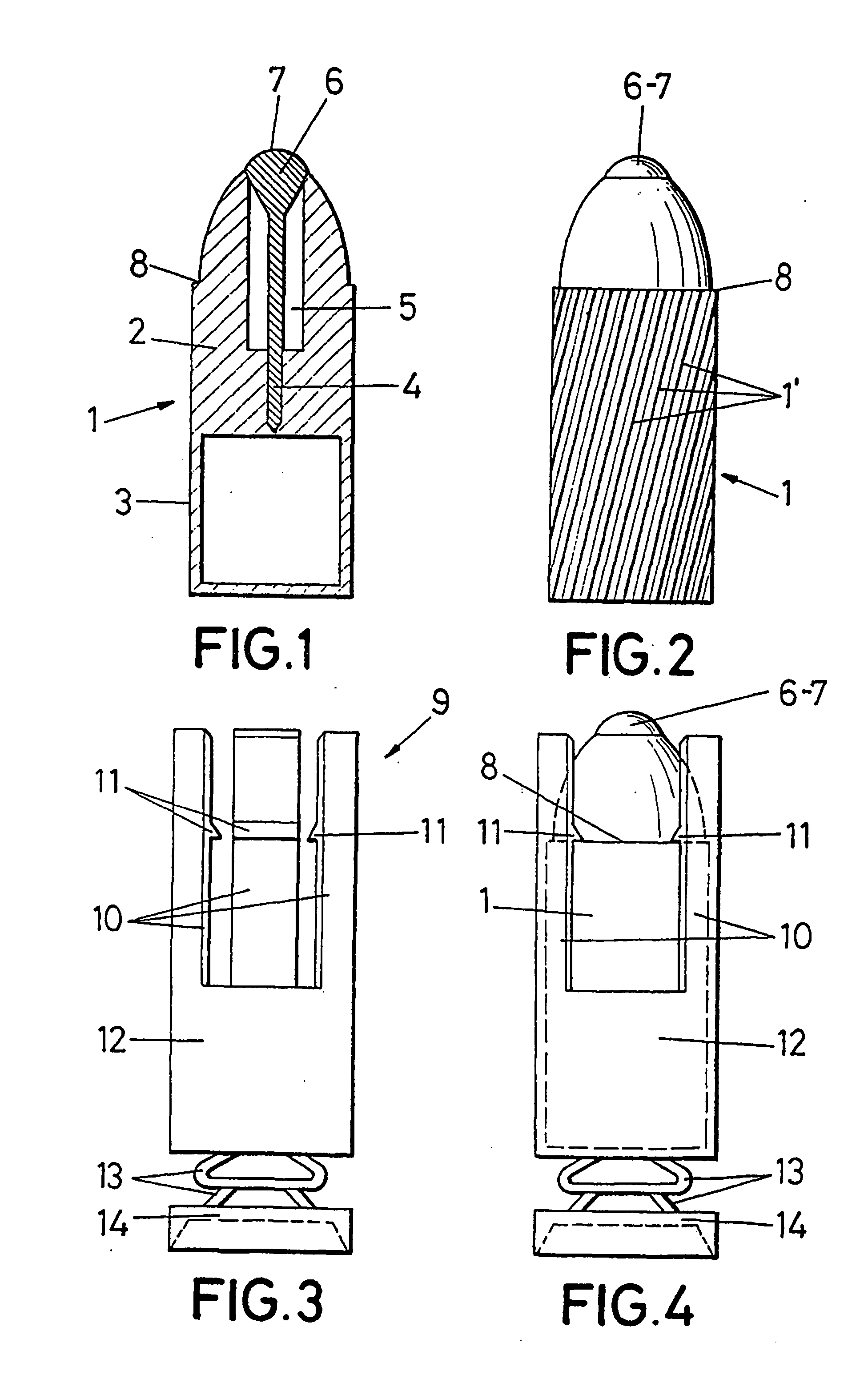

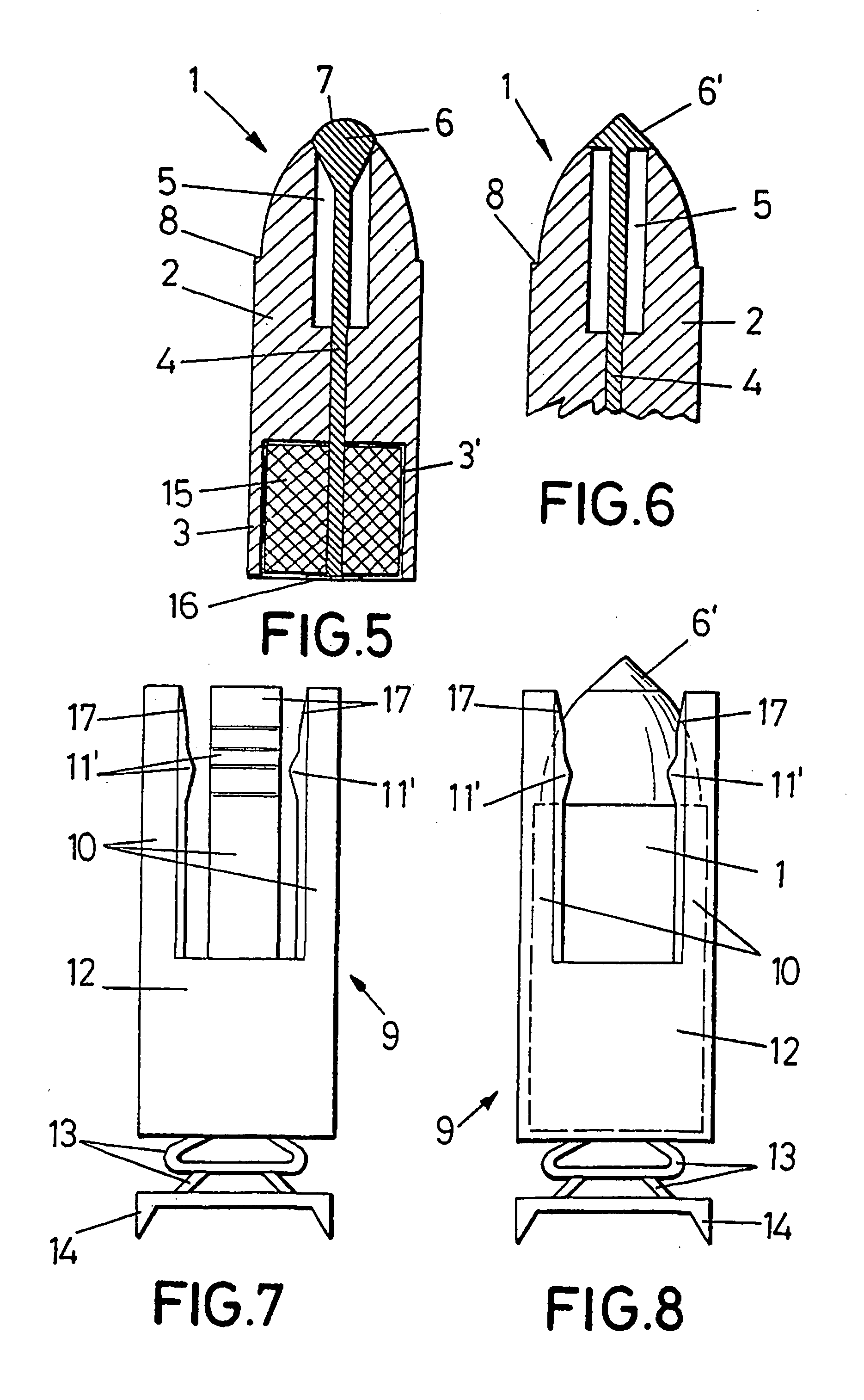

[0037] This projectile is called sub-calibrated as it has a diameter less than that of the barrel it is shot from, with the aim of not damaging the weapon's barrel, reducing the diameter so that it incides in the air layers it traverses more easily. This projectile is situated within a plastic block which makes it better fit in the barrel and avoid the projectile from rubbing against the weapon's walls.

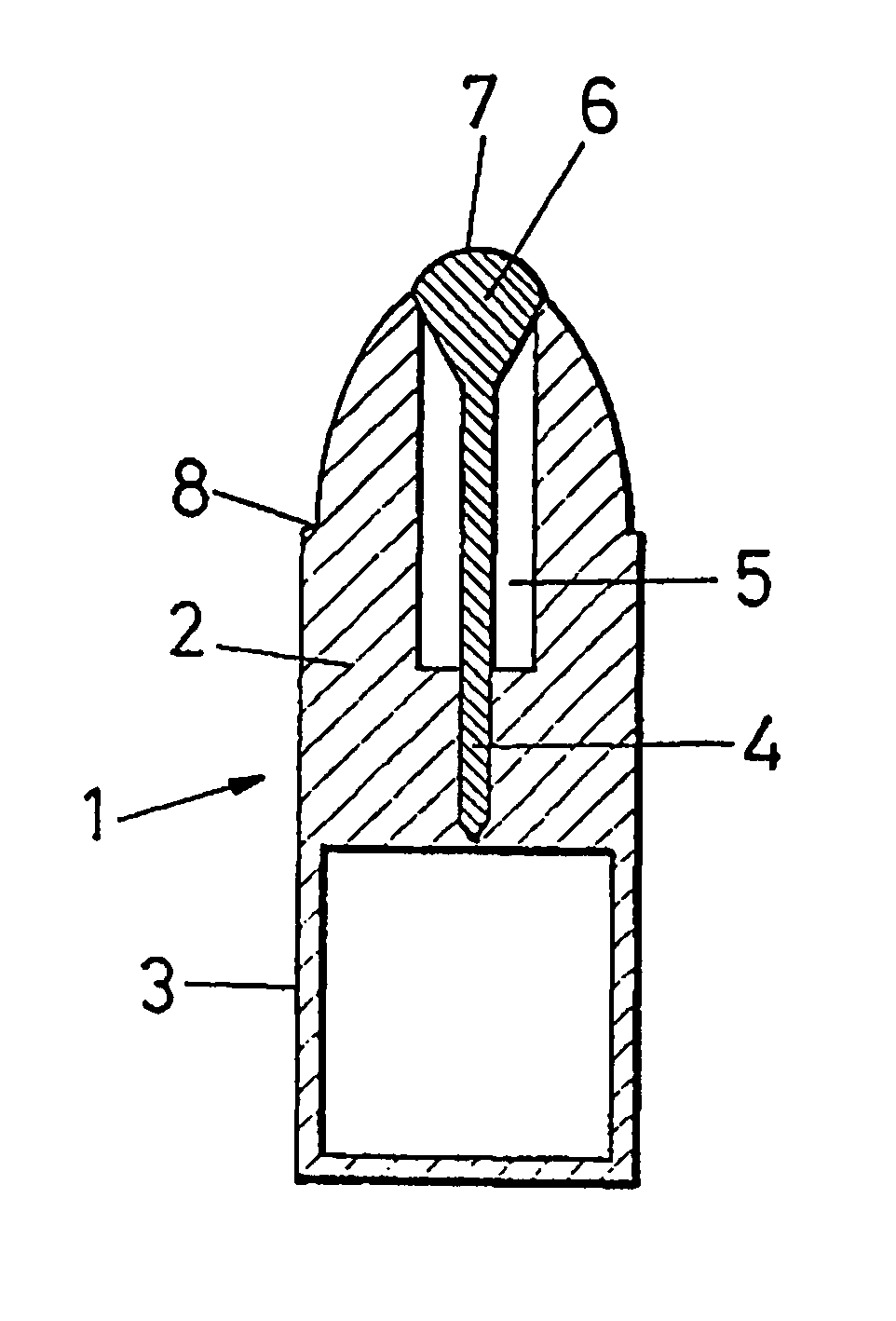

[0038] As may be seen in the aforementioned figures, the projectile (1) of the invention comprises a body with a front part (2), a totally hollow rear part (3), a rod (4) mounted in the front part which is held in place under pressure and passes axially and continuously through a chamber (5) located in the front part (2). The rod (4) terminates in a conically shaped tip (6). The external face of the tip has the form of a cap (7) or convex curve. Due to the tip's (6) taper, it fits into the mouth of the chamber (5), as shown clearly in FIG. 1. The body (1) of the projectile is cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com