Boat lift canopy assembly

a technology of canopy cover and assembly, which is applied in the direction of vessel construction, building types, construction, etc., can solve the problems of reducing the aesthetic appeal of the cover, affecting the aesthetics of the wrapped canopy cover and the integrity of the fabric, and being expensive and often impractical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

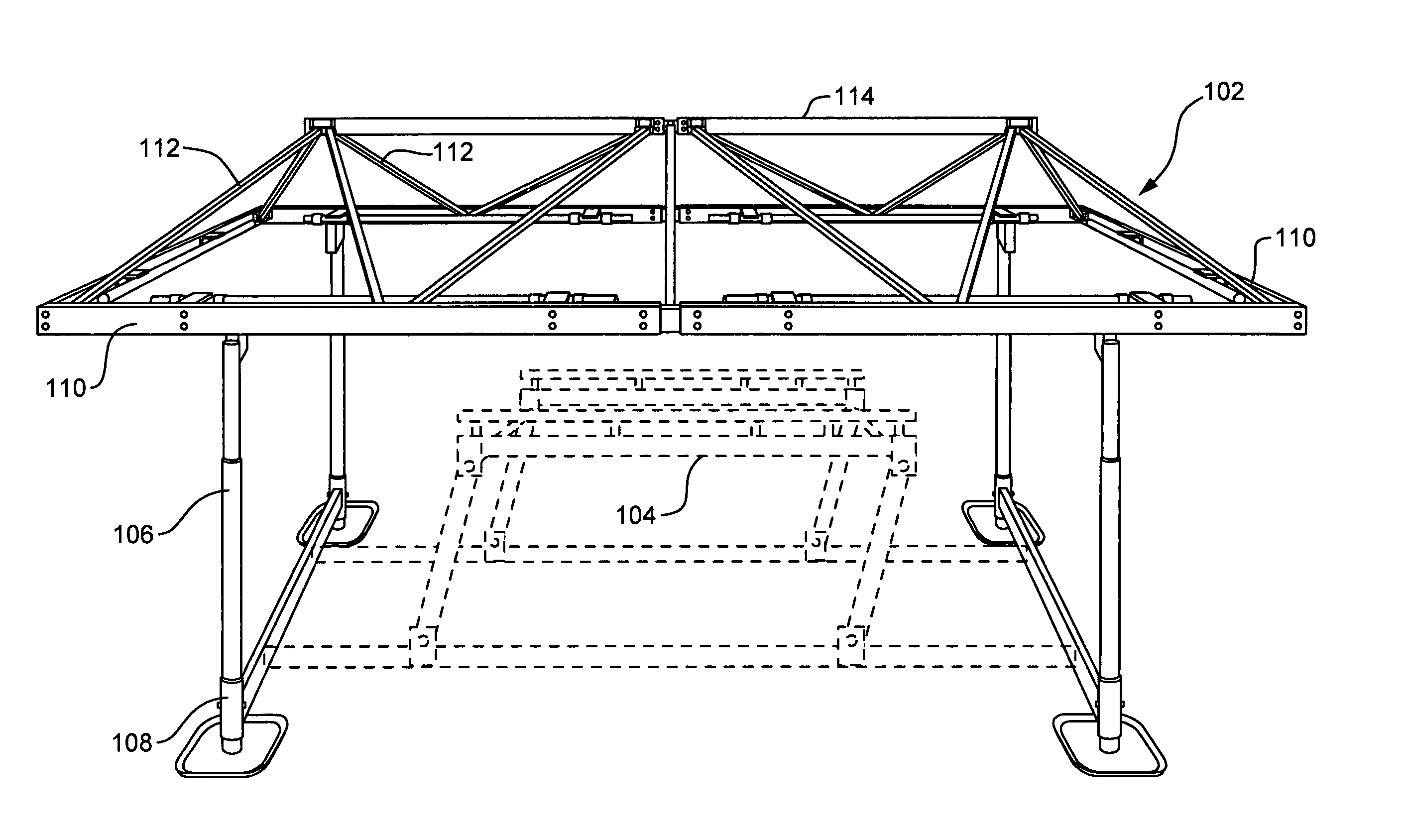

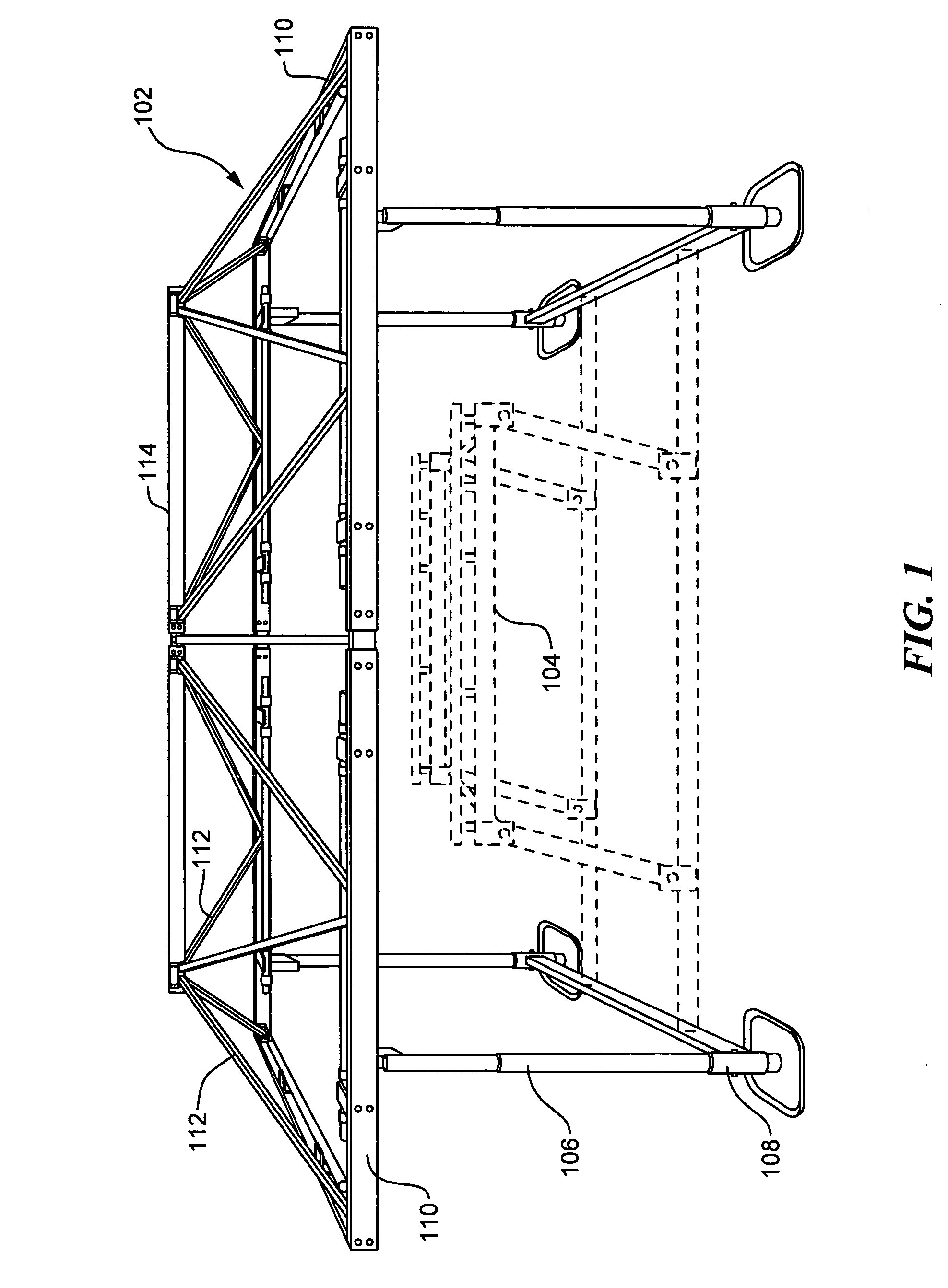

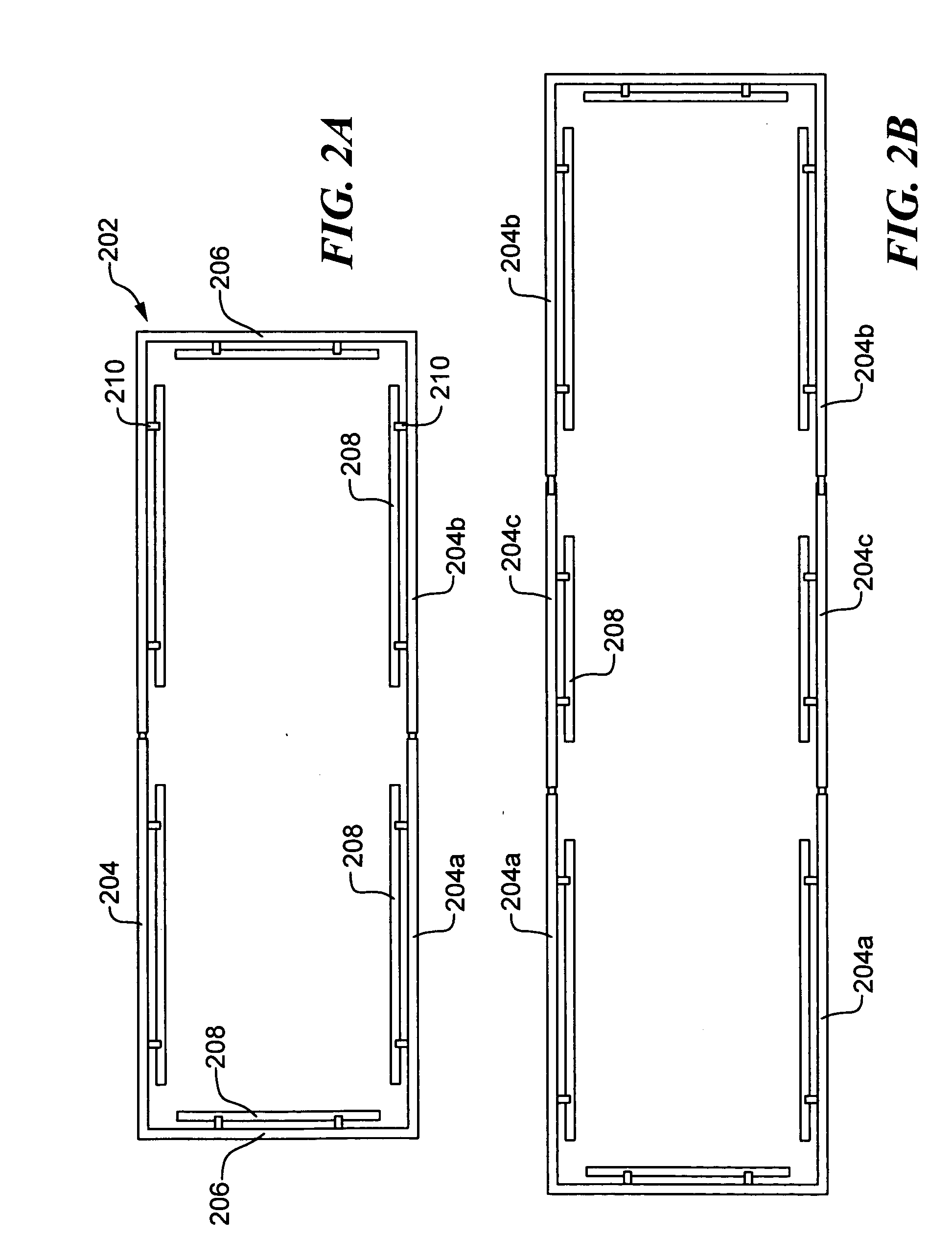

[0023] Turning now to FIG. 1, depicted is an embodiment of the present invention. Canopy 102 sits over a watercraft lift 104. Lift 104 may be any form of watercraft lift designed to be affixed to the bottom of a body of water, such as described in U.S. Pat. No. 5,908,264 to Hey or U.S. Pat. No. 5,184,914, issued to the inventor of the present invention and which is incorporated herein by reference. Alternatively, lift 104 may be a floating lift as described in U.S. Pat. No. 5,485,798 to Samoian et al., or U.S. patent application Ser. No. 10 / 816,992 by the inventor of the present invention, incorporated herein by reference.

[0024] Canopy 102 is suspended above lift 104 by upright members 106. Lifts affixed to the bottom of the body of water, such as '264 and '914 cited above, generally sit upon legs 108, and in such case upright members 106 may simply be vertical extensions of legs 108. Alternatively, members 106 may be affixed to some other part of lift 104, or members 106 themselve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com