Modified ball structure

a ball structure and modified technology, applied in golf balls, golf balls, non-inflatable balls, etc., can solve the problems of inability to determine the flying direction and distance of a golf ball struck, the golf ball cannot help a golfer to examine where he or she makes errors, and the golf ball cannot be used by beginners to achieve correctness. , to achieve the effect of enhancing the rotation rate or speed, and improving the performance of the golf ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

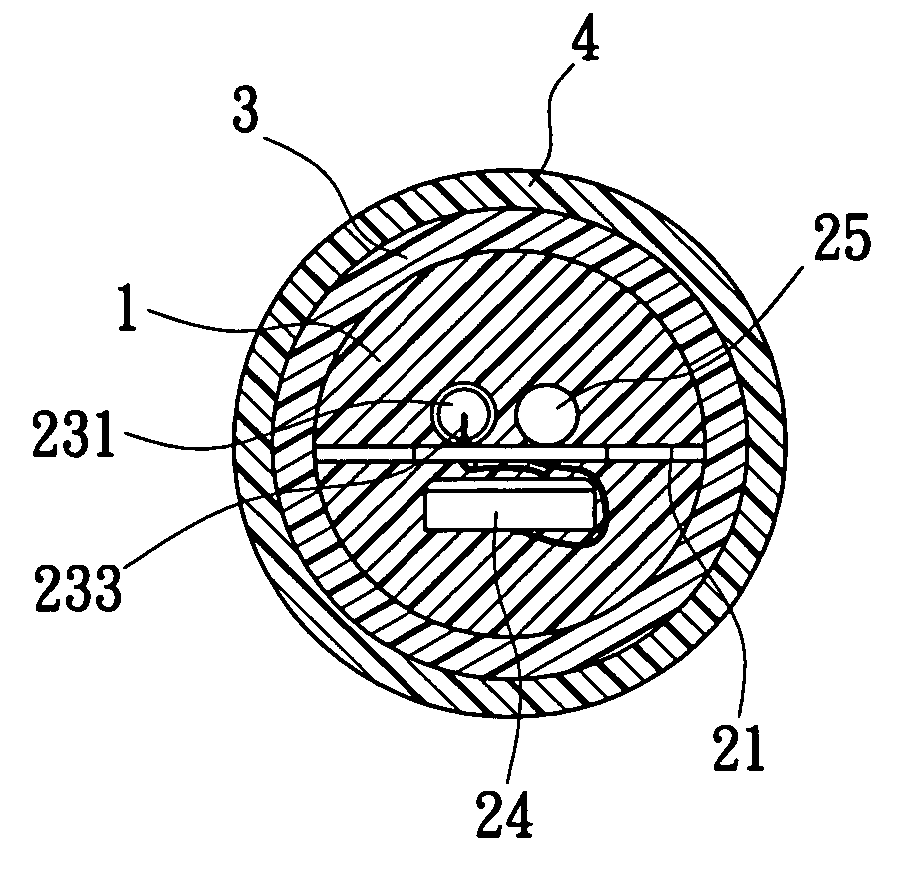

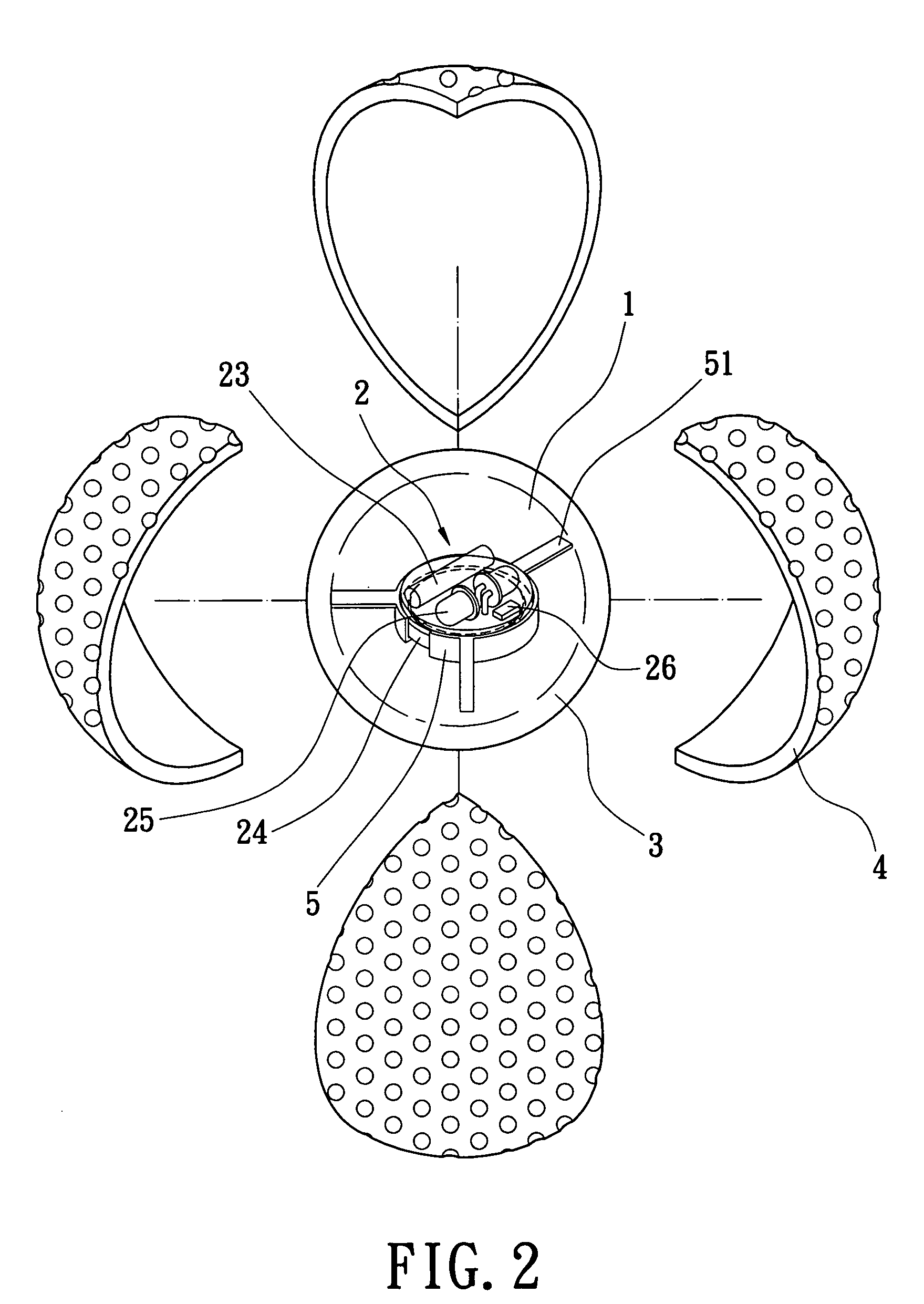

[0029] The present invention proposes a modified ball structure. In the embodiment, the ball is a golf ball. As shown in FIGS. 2 to 5, the modified ball structure comprises a transparent hard inner body 1, a light emission control module 2, a transparent rubbery intermediate body 3, a spherical transparent outer body 4 and a base 5.

[0030] The transparent hard inner body 1 is a rubbery spherical transparent inner body, which is formed by embedding an upper rubber and a lower rubber.

[0031] The base 5 is disposed at the center of the transparent hard inner body 1 having an accommodation room (not shown). More than two fixing components 51 are annularly disposed outside the accommodation room. The fixing components 51 are columnar. Because the base 5 is sheathed by the transparent hard inner body 1, the deviation of its subassemblies can be avoided.

[0032] The light emission control module 2 is disposed in the accommodation room, and has a circuit board 21 with a detection switch 23 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com