Ammonium nitrate blasting agent and method of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention may be embodied in a number of different forms. However, the specification and drawings that follow describe and disclose only some of the specific forms of the invention and are not intended to limit the scope of the invention as defined in the claims that follow herein.

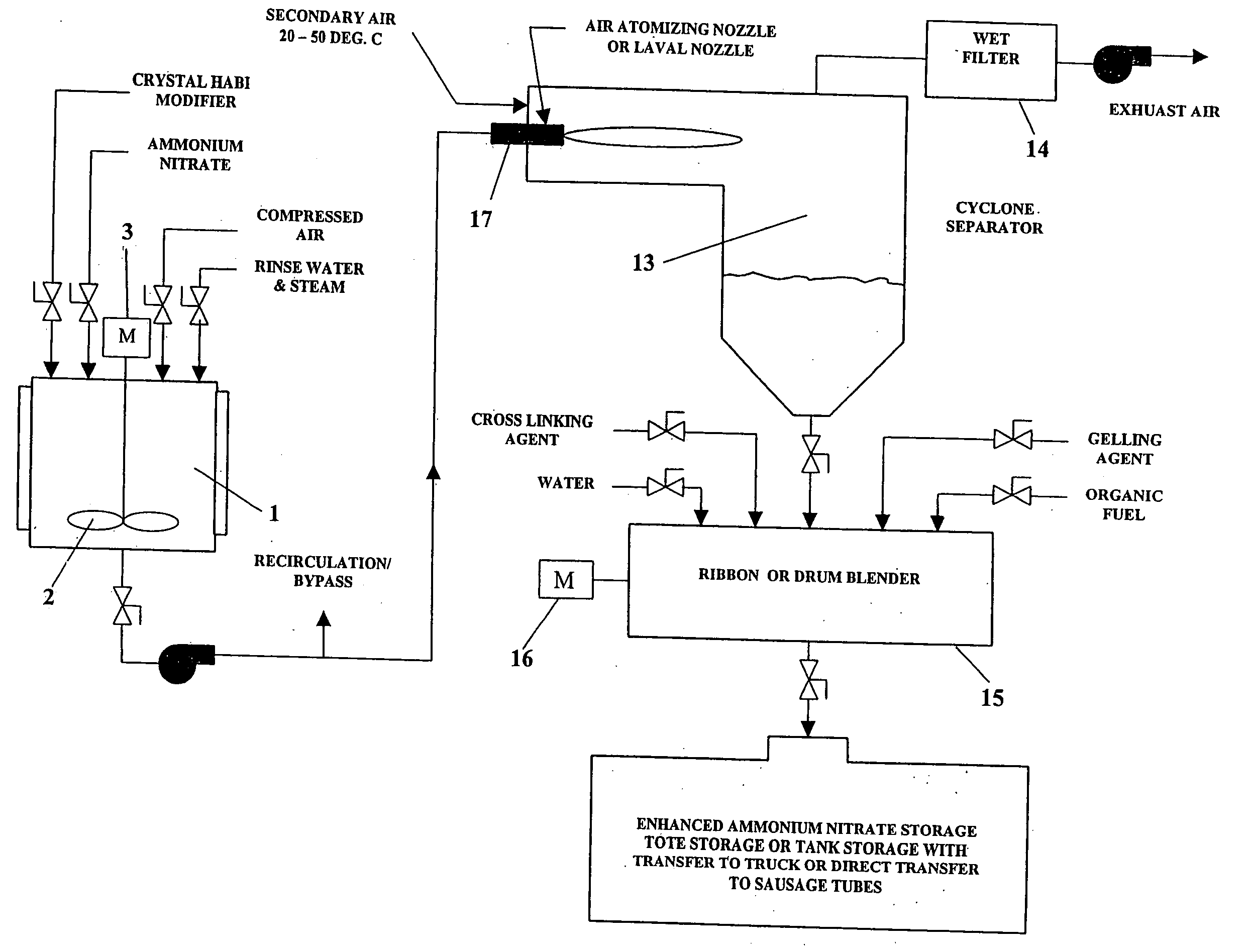

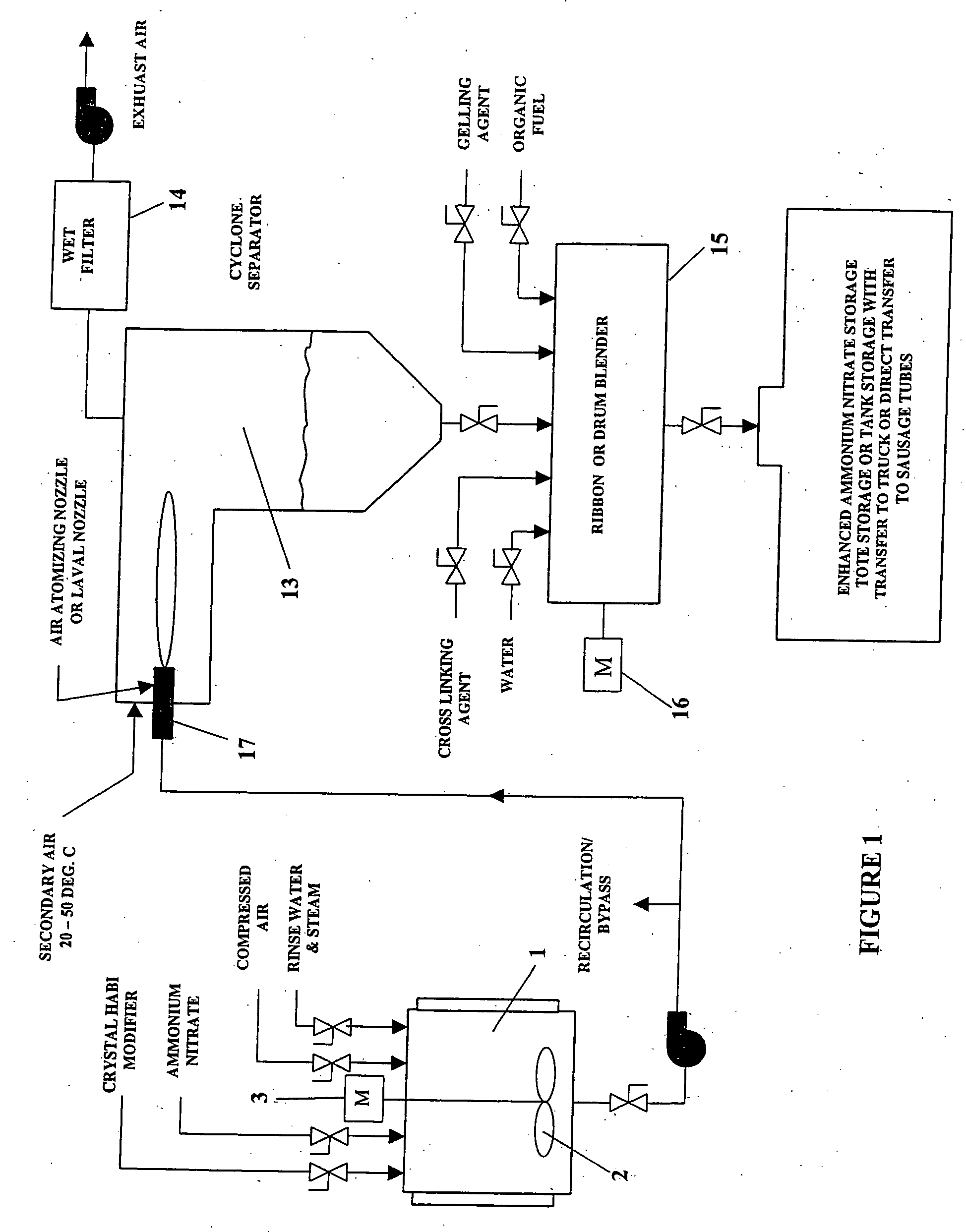

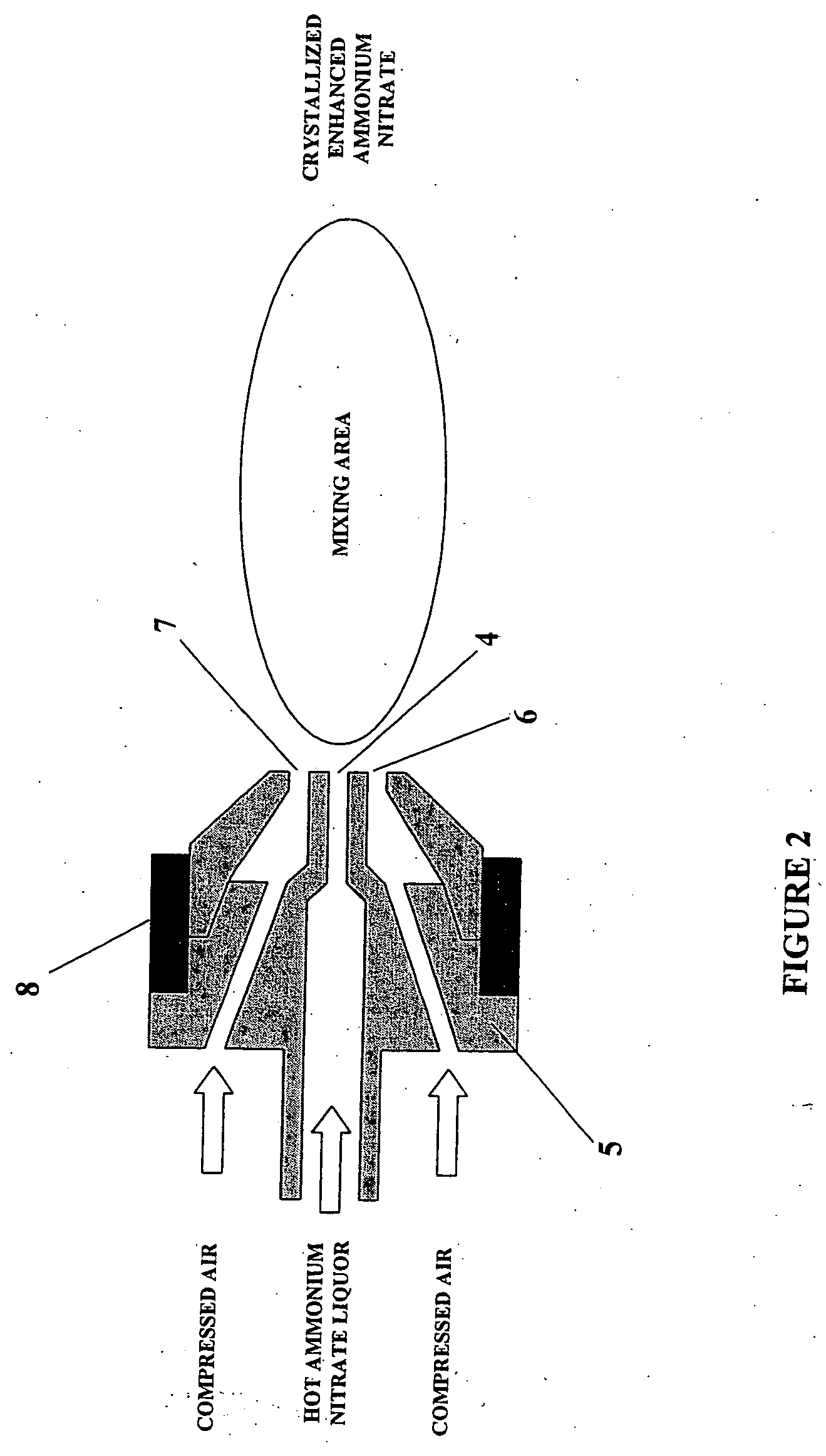

[0020] A method of producing an ammonium nitrate blasting agent in accordance with one of the preferred embodiments of the present invention is shown schematically in FIG. 1. The method consists of three primary steps or stages; namely, the mixing of an aqueous solution of ammonium-nitrate and a crystal habit modifier, the formation of fine grained ammonium nitrate crystals, and the combination of the ammonium nitrate crystals with an organic carbonaceous fuel, with or without various other additives, to form an ammonium nitrate blasting agent. Each of these primary stages will now be described in more detail.

[0021] With reference to FIG. 1, an aqueous solution of ammonium nitrate may ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com