Moving camera mount

a camera and mounting system technology, applied in the direction of machine supports, instruments, transportation and packaging, etc., can solve the problems of insufficient stiffness of the rails to be self-supporting, the limitations of the various methods of moving cameras, and the heavy weight of the typical dolly method for many applications, etc., to achieve the effect of reducing weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

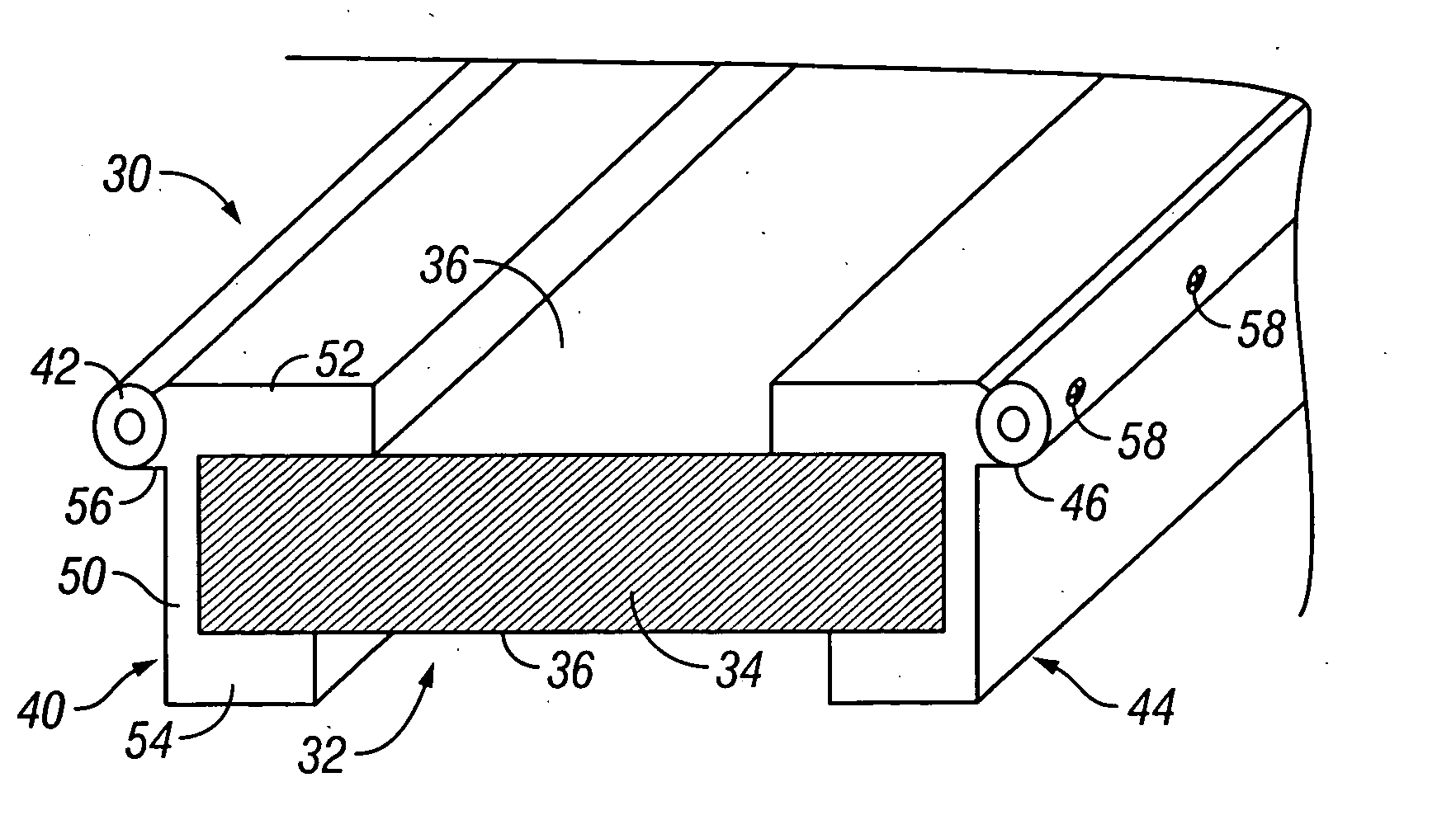

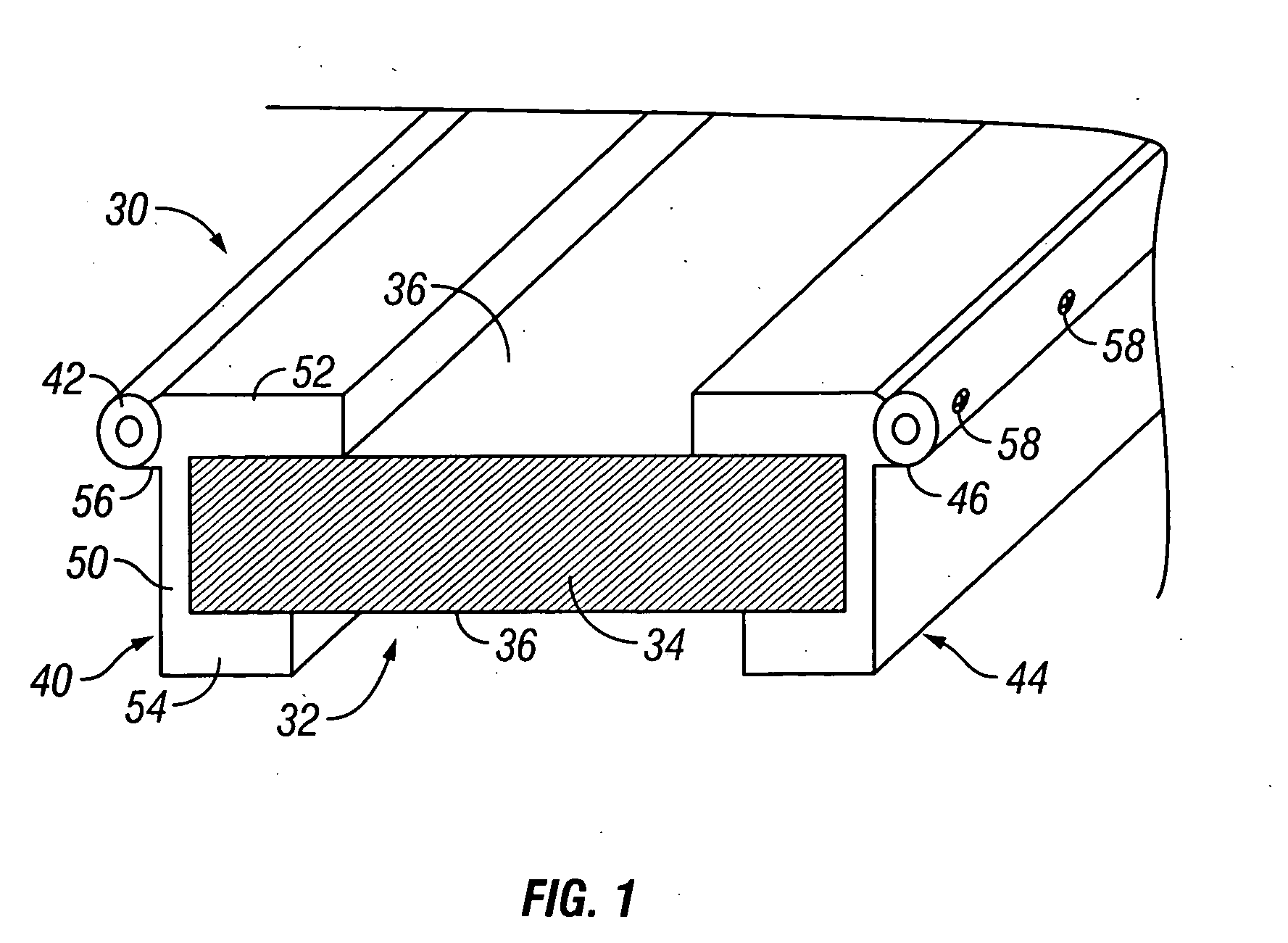

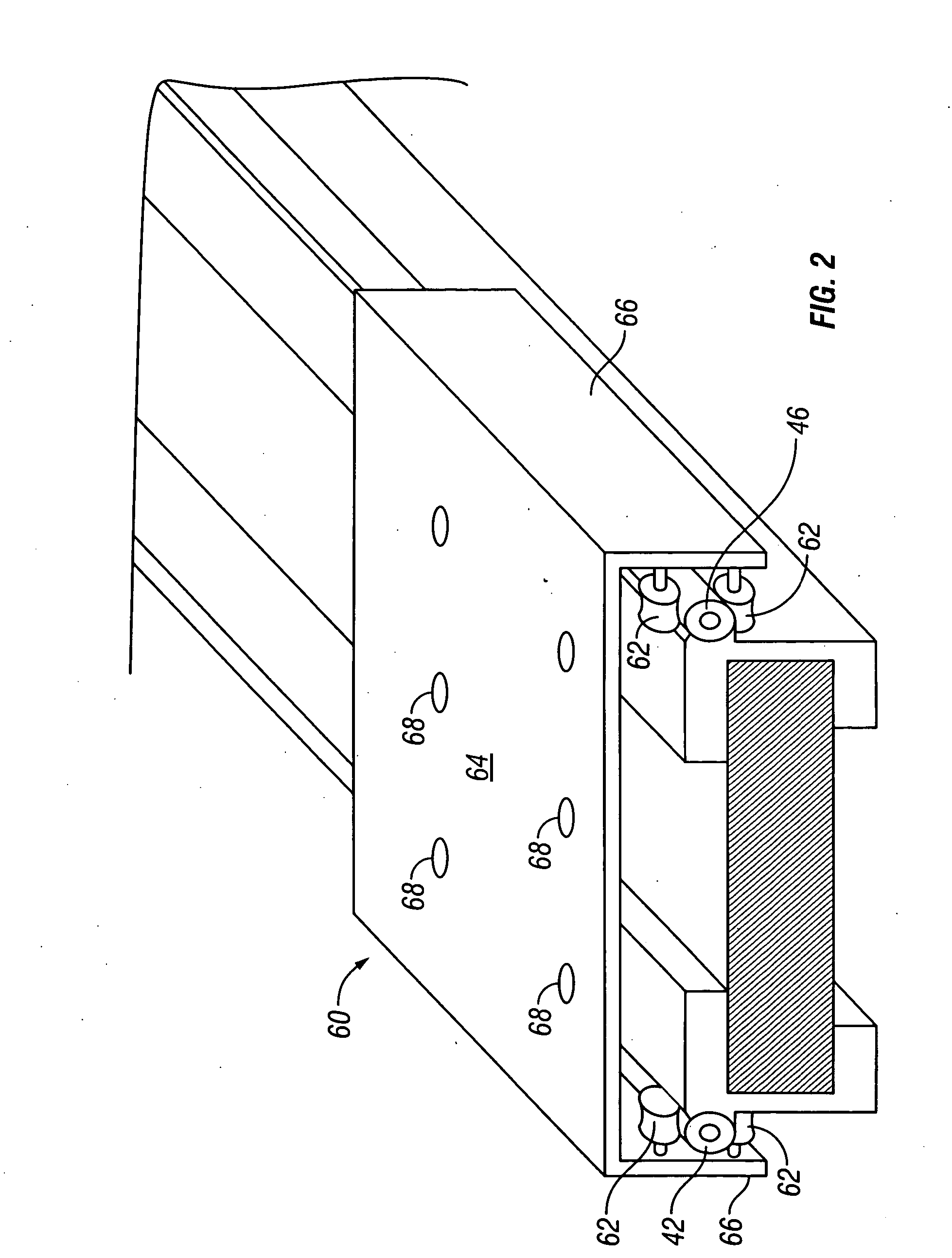

[0028] In preferred embodiments, the rail system comprises a rail 30 configured to receive a moving apparatus, such as sled having a platform for mounting a movie camera as shown in the multiple figures. As depicted in FIG. 1, the rail 30 comprises a core 32, positioned between a pair of opposing fixtures 40 and 44 for precision location of a pair of oppositely disposed shafts 42, 46 mounted on respective of the fixtures 40 and 44. The shafts 42, 46 extend along the length of the rail 30 in a longitudinal direction, wherein the shafts 42 and 44 are fixedly mounted on opposing sides of the rail 30 in which the core 32 resides.

[0029] Fixtures 40 and 44 are roughly ‘C’ shaped mirror image channels having a base 50, a top flange 52 and bottom flange 54. The top flange 52 and bottom flange 54 are spaced apart by the thickness of the core 32, so that the core 32 is captured in the ‘C’ shaped channel defined by the fixtures. A wedge 56, positioned opposite top flange 52 on the outer side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com