Metal hydride based vehicular exhaust cooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

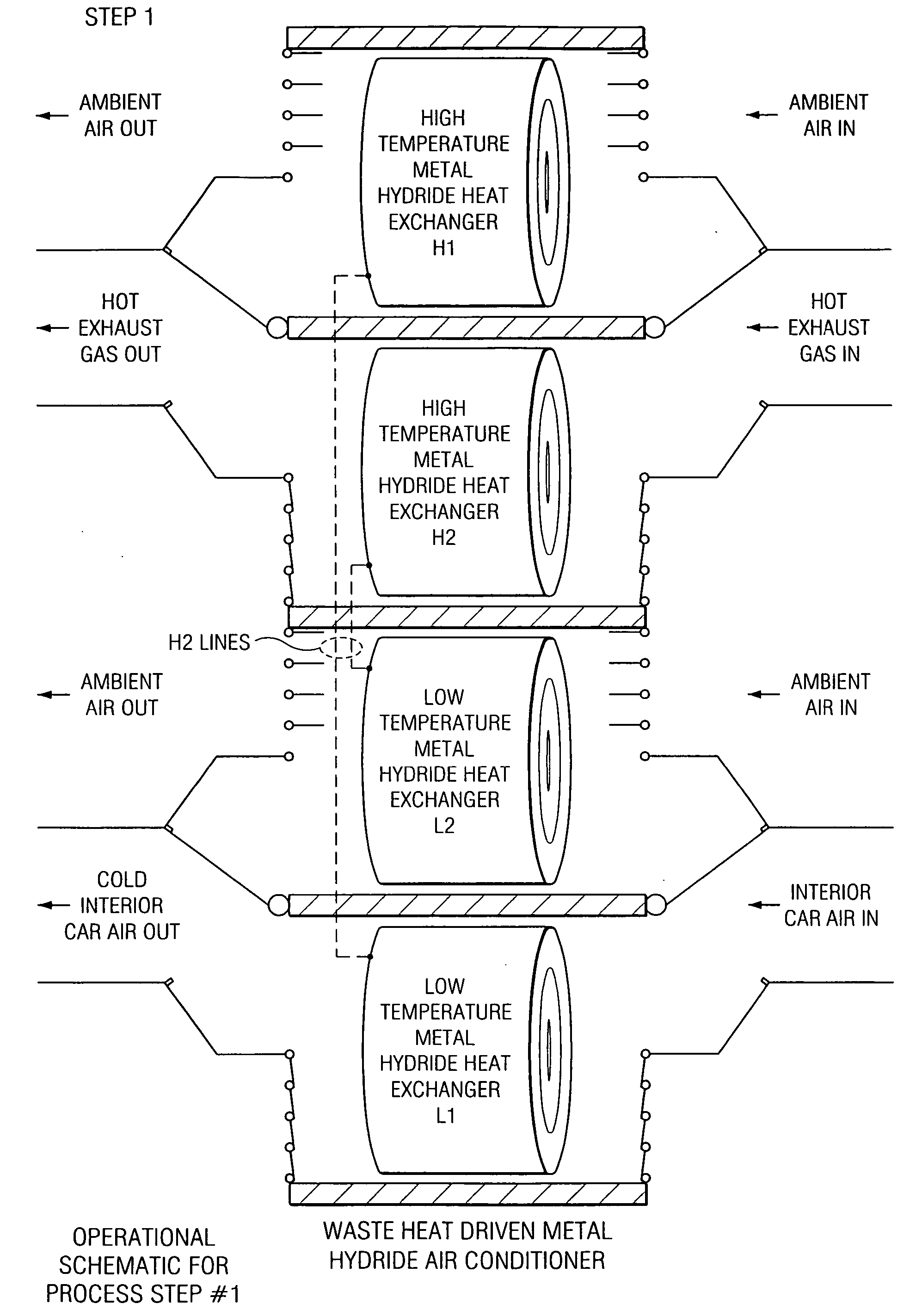

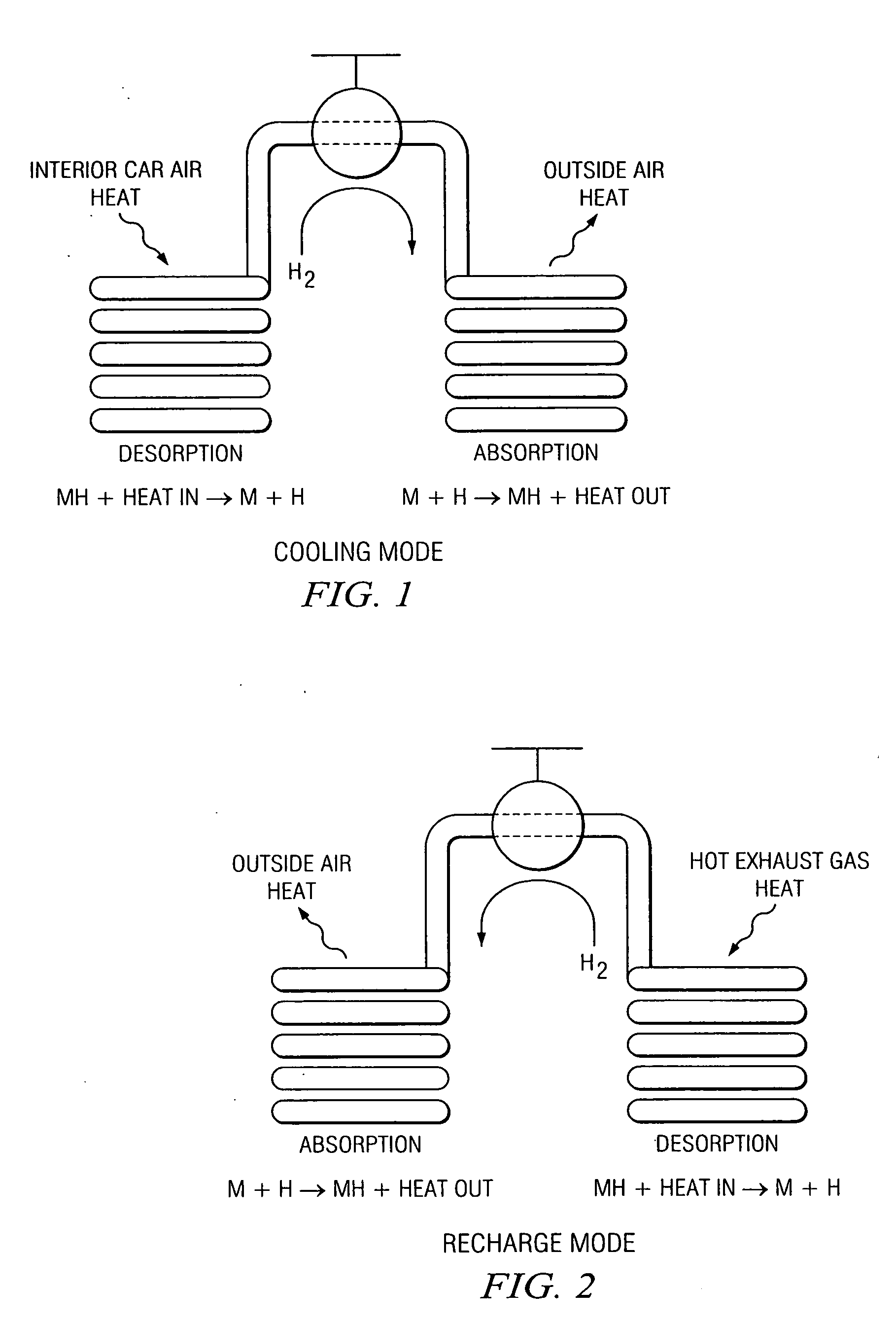

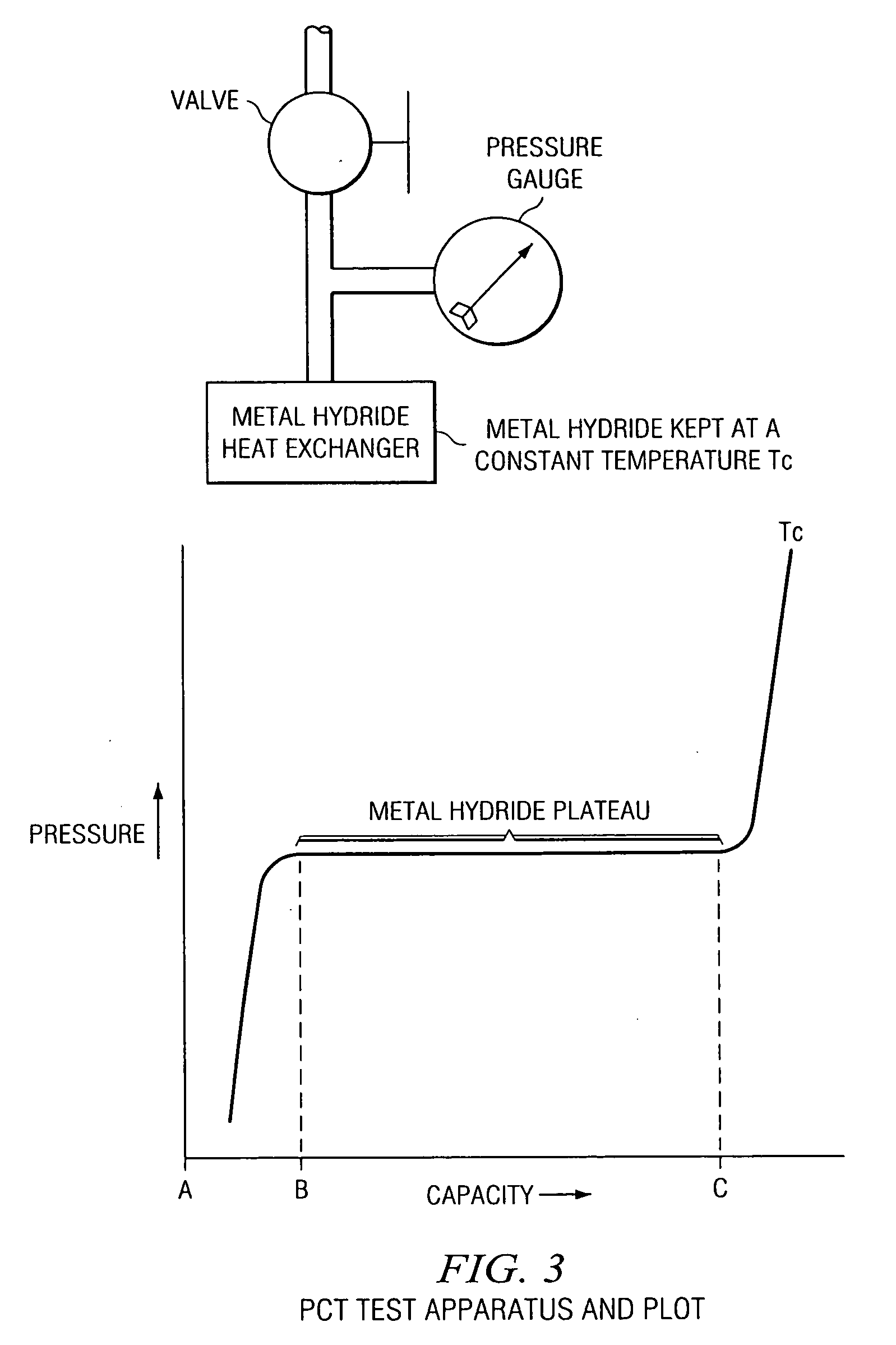

[0037] There are a number of metals that possess the remarkable ability to absorb large quantities of hydrogen gas. Absorption occurs under specific temperature and pressure conditions. The hydrogen is released (desorbed) when the alloy temperature is elevated or the pressure is reduced. The absorption / desorption phenomenon is a “reversible” reaction and the metals that absorb hydrogen are called reversible metal hydride materials.

[0038] When a reversible metal hydride material absorbs hydrogen gas, heat is given off; the reaction is exothermic. In order to desorb hydrogen from the metal hydride material, heat is required; the reaction is endothermic. If the desorbing material takes its heat from ambient temperature air, the air temperature decreases, thus producing the refrigeration associated with air conditioning.

[0039] The reversible metal hydride reaction can be expressed in the simplified chemical equation:

M+H⇄MH

where M is a metal or metal alloy and H is hydrogen. The top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com