Flexible debris collection apparatus

a technology of debris collection and flexible materials, which is applied in the field of cleaning implements, can solve the problems of not providing the user with any flexibility as to the form of the apparatus, each of the prior art devices falls short of the optimum configuration of the debris collection apparatus, and the hoefler device is fabricated of flexible materials, so as to achieve the effect of reducing the number of hoeflers, and reducing the number of hoefler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

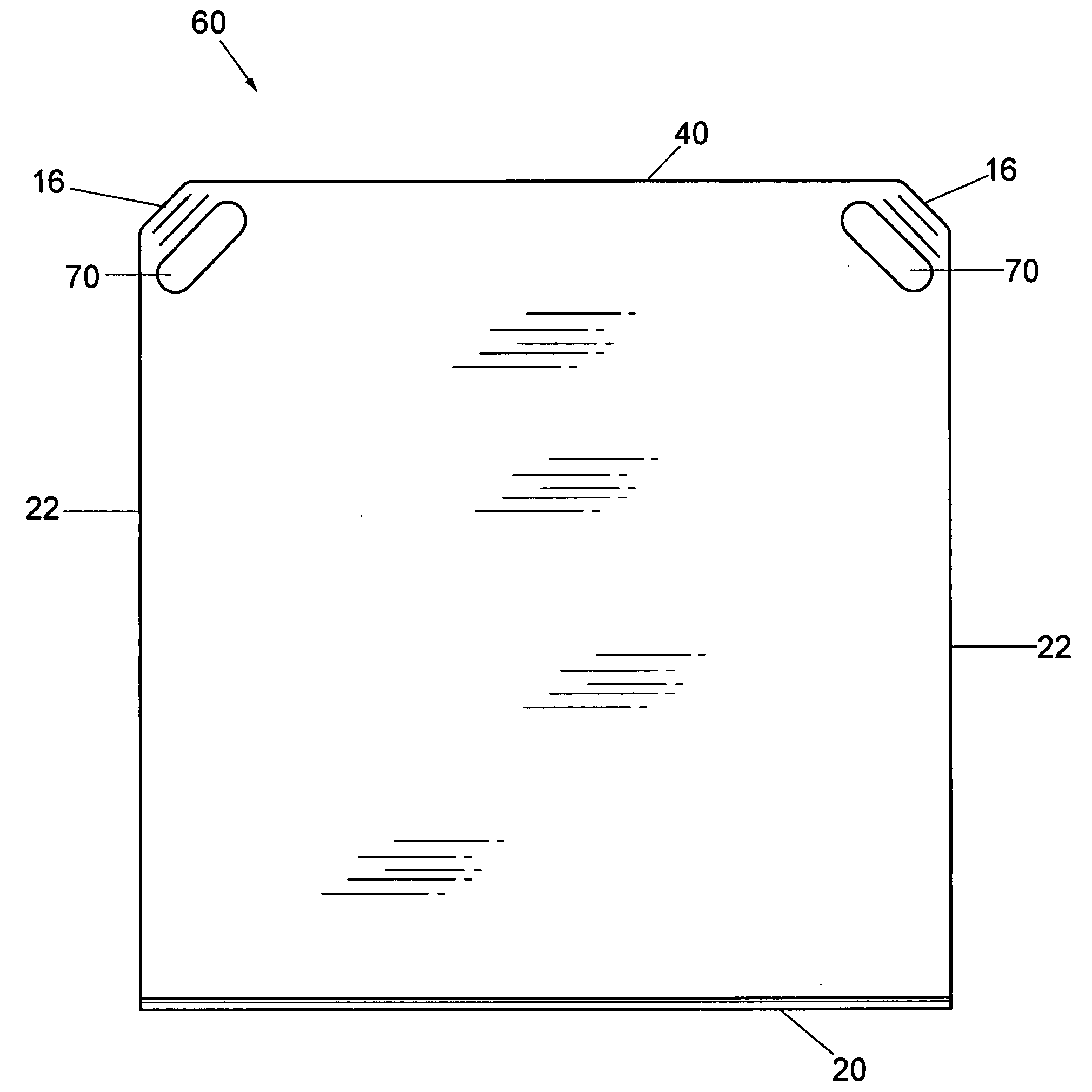

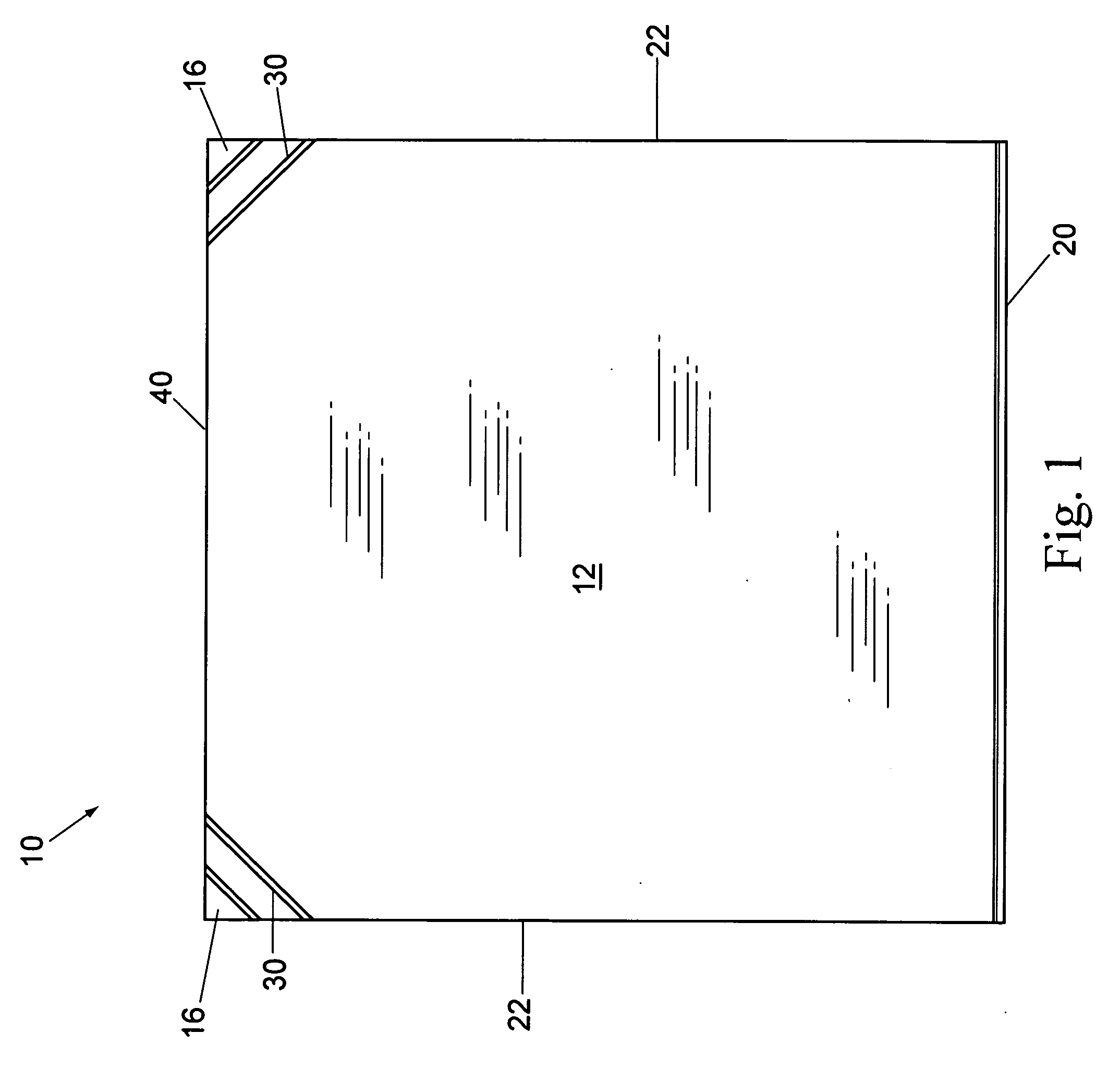

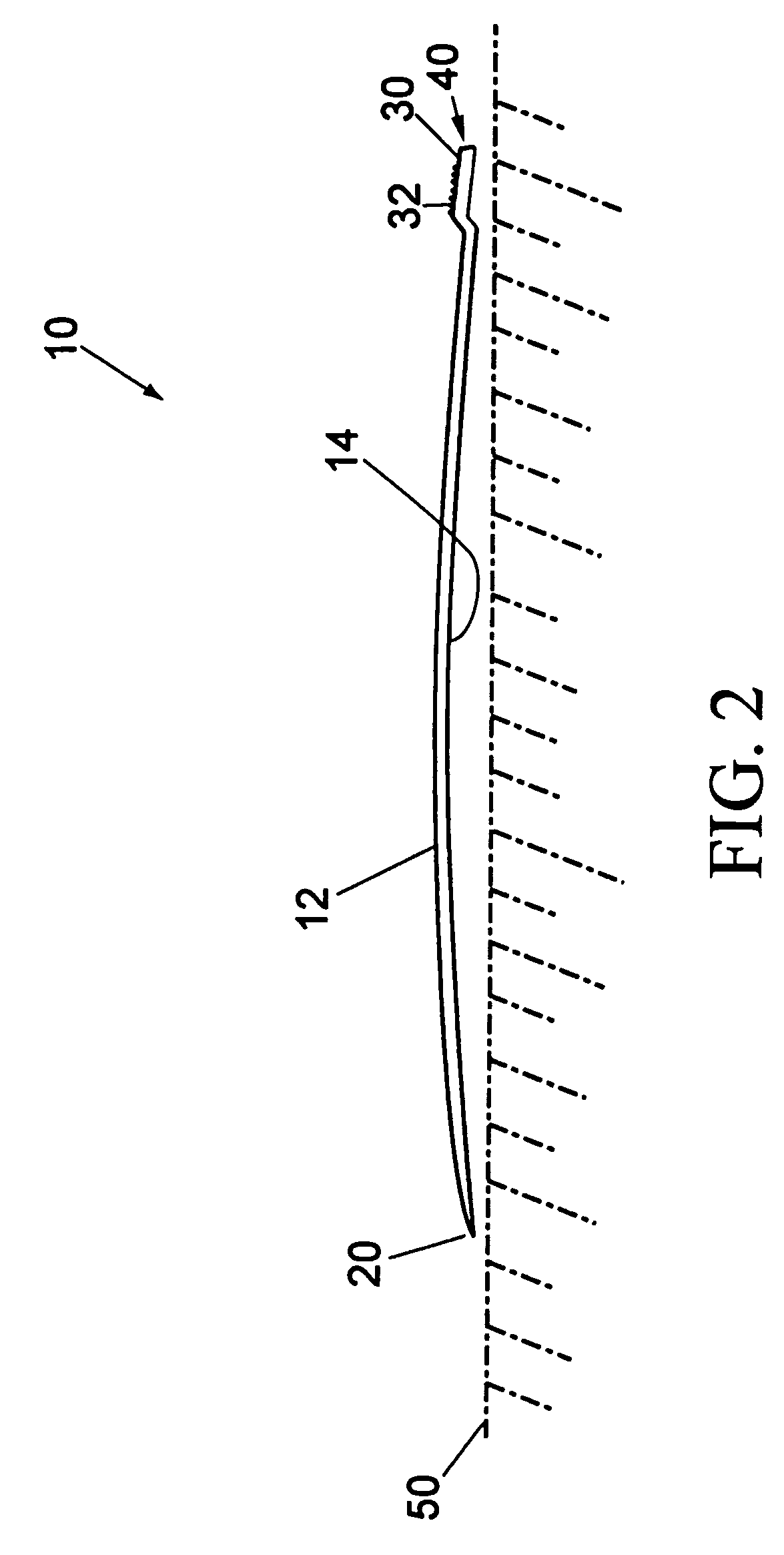

[0027]FIGS. 1 and 2 are, respectively, top and side views of a flexible debris collection apparatus 10 according to a preferred embodiment of the present invention. The apparatus 10 generally comprises a rectangularly-shaped sheet (i.e. possessing four 90° corners) with a top surface 12 and a bottom surface 14. The apparatus 10 is preferably fabricated from polypropylene, polycarbonate, or other flexible, resilient, commercially-available plastic sheet stock formed by sheet extrusion using conventional methods. The extruded sheet stock in roll form is then economically die-cut and stamped into the illustrated form. One skilled in the art will understand that any material possessing an appropriate amount of flexibility and resiliency may be used, and other suitable manufacturing methods may be employed such as an injection molding process. Additionally, while the rectangular form may be preferred, the apparatus 10 of the present invention may take a different quadrilateral shape, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com