Method for recycling/reclaiming a monitor wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

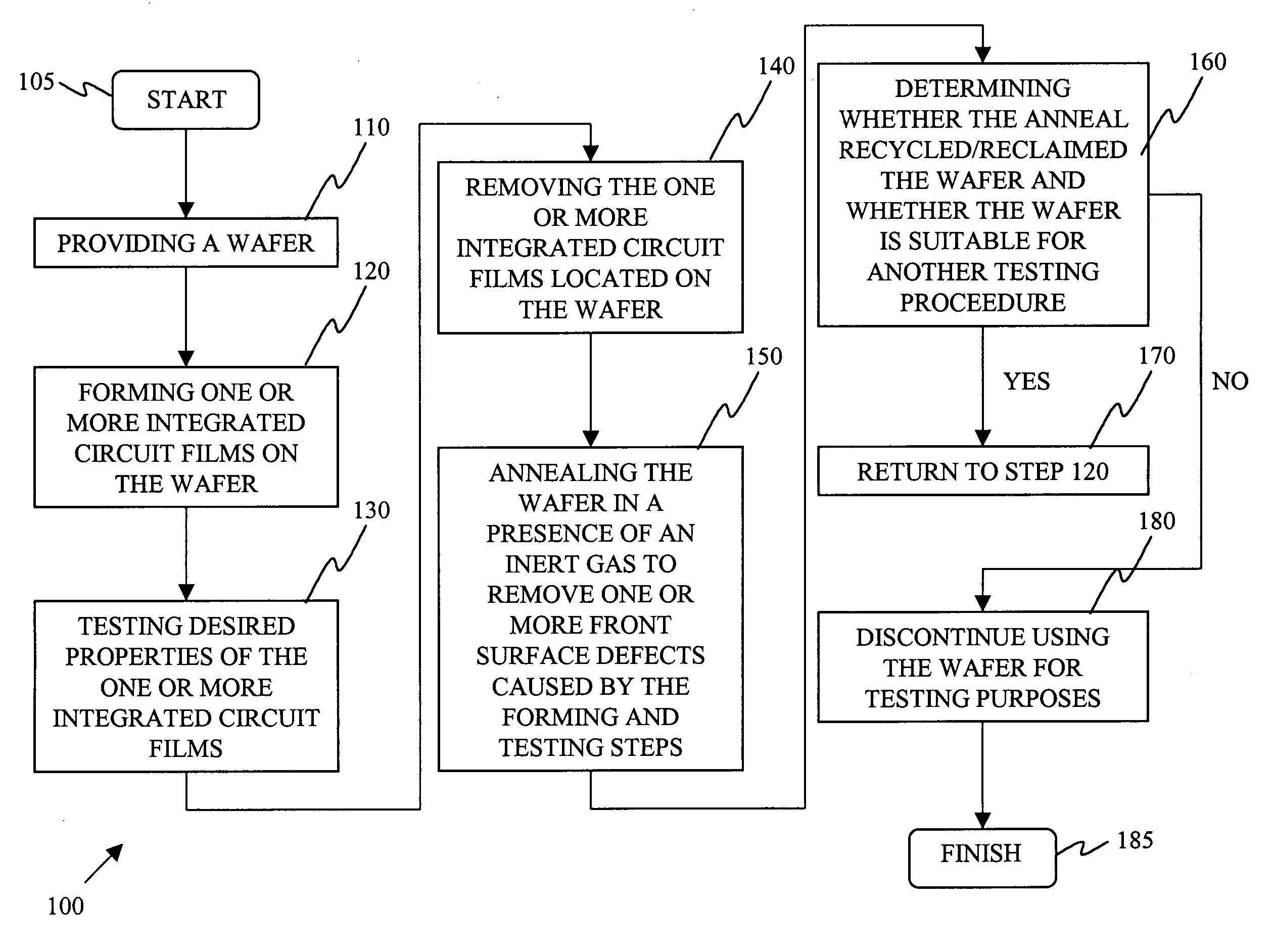

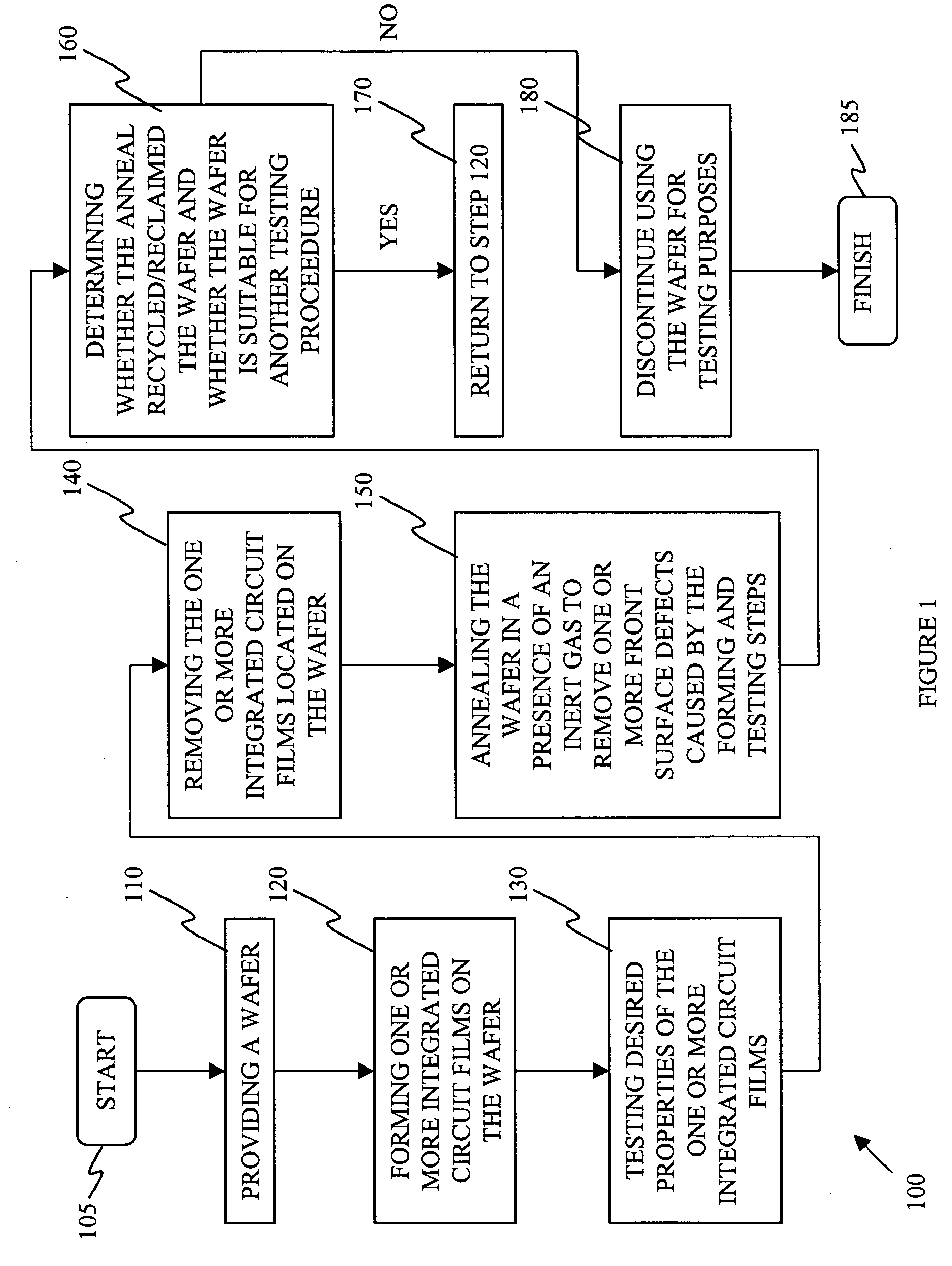

[0011] The present invention, in contrast to the prior art, begins with the unique recognition that if front surface defects on a monitor wafer caused during either the formation of the integrated circuit (IC) films on the monitor wafers or the testing of those films can be corrected, the effective useful life of the monitor wafer can be greatly increased. Namely, the present invention has recognized that if the front surface effects can be corrected, less lapping and polishing of the monitor wafer is required to sufficiently correct those front surface defects during the recycling / reclamation process. Therefore, the monitor wafer, and more specifically the thickness of the monitor wafer, withstands many more recycling / reclamation processes before being unsuitable for additional testing purposes.

[0012] Given the aforementioned recognition, the present invention observed that by annealing the monitor wafer in a presence of an inert gas, one or more of the front surface defects creat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com