Electric percussion instruments

a technology of electric percussion and percussion drums, applied in the field of musical instruments, can solve the problems of loss of fidelity on toms and bass drums, more complicated, and high cost of close micing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Double-Headed Electric Drum

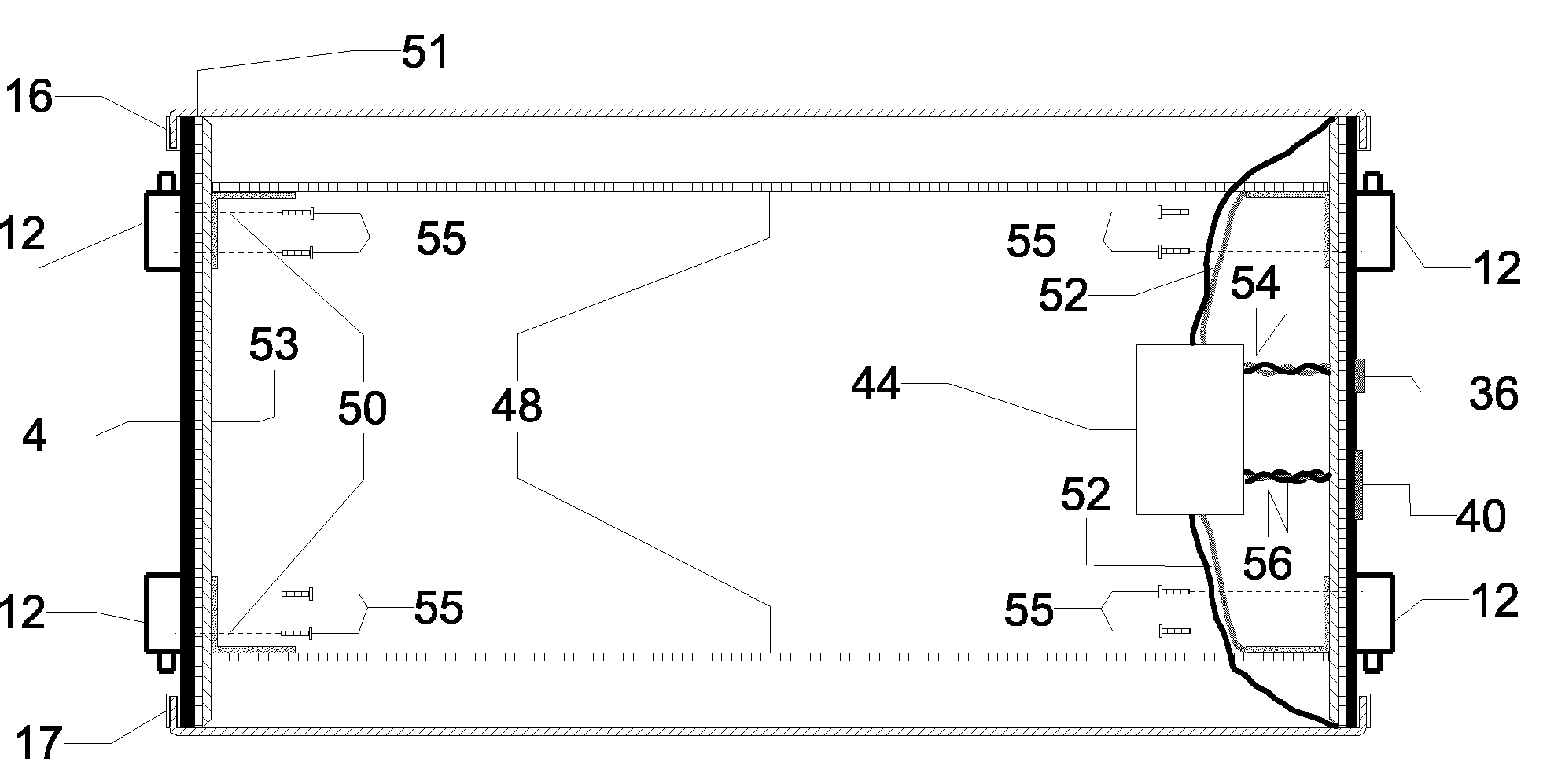

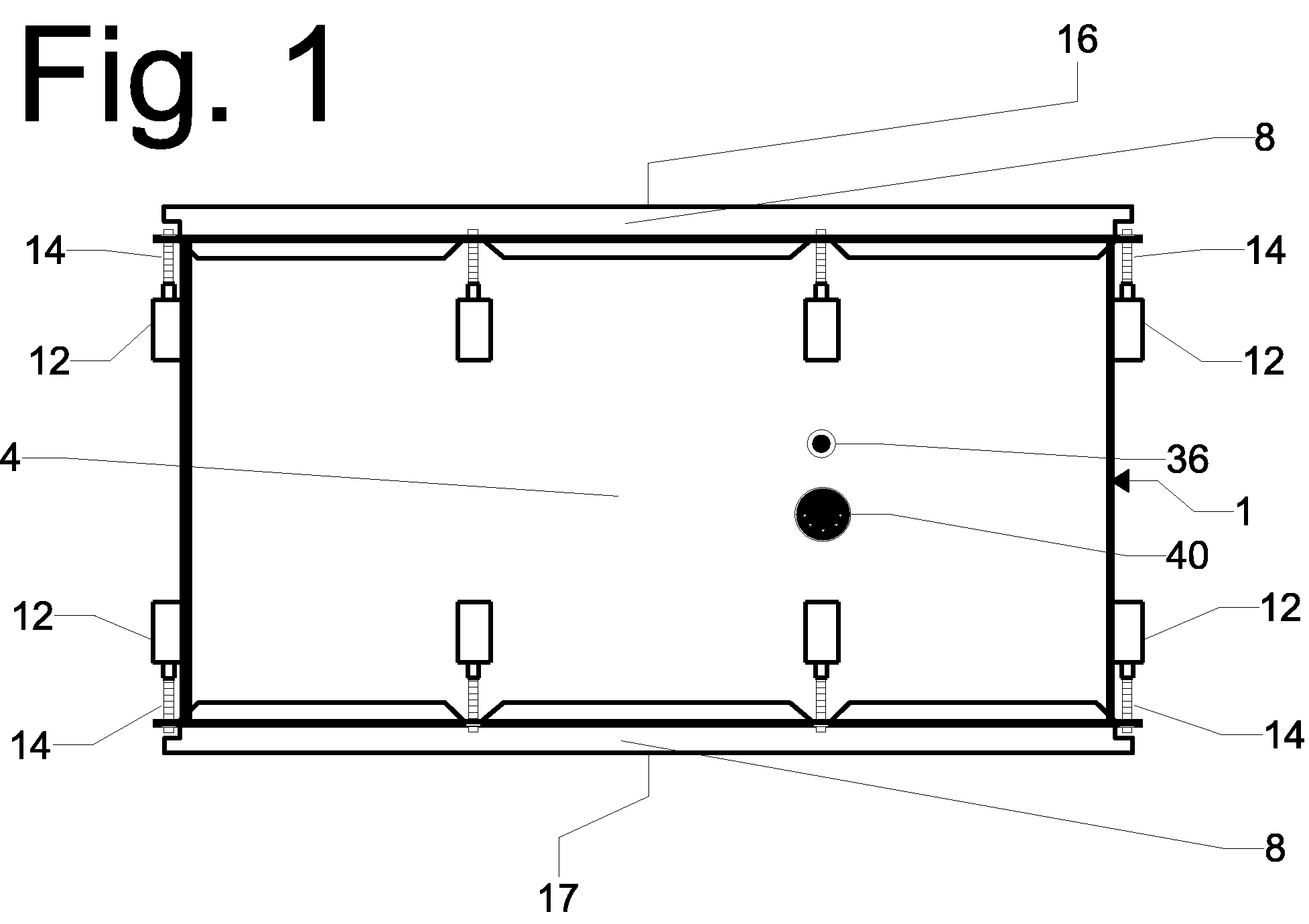

[0030] Referring now to the drawings, FIG. 1 depicts an embodiment of the invention, a double-headed electric drum 1. It consists of a cylindrical shell assembly 4 capped on top by a batter drumhead assembly 16, and on the bottom by a resonant drumhead assembly 17. The drumhead assemblies 16 and 17 are held taut on the drum by metal hoops 8, which are attached to the shell assembly by threaded tension rods 14 screwed into metal lugs 12. In this embodiment, there are six evenly-spaced lugs per shell end attached to the shell assembly. FIG. 1 also depicts an audio output jack 36, which is used to connect the drum to industry standard recording and amplification equipment. In this embodiment, the audio connection is through a standard ¼″ instrument cable (not shown). Power is supplied to the drum through the power input port 40, which connects to widely available grounded DC power supplies through a cable (not shown).

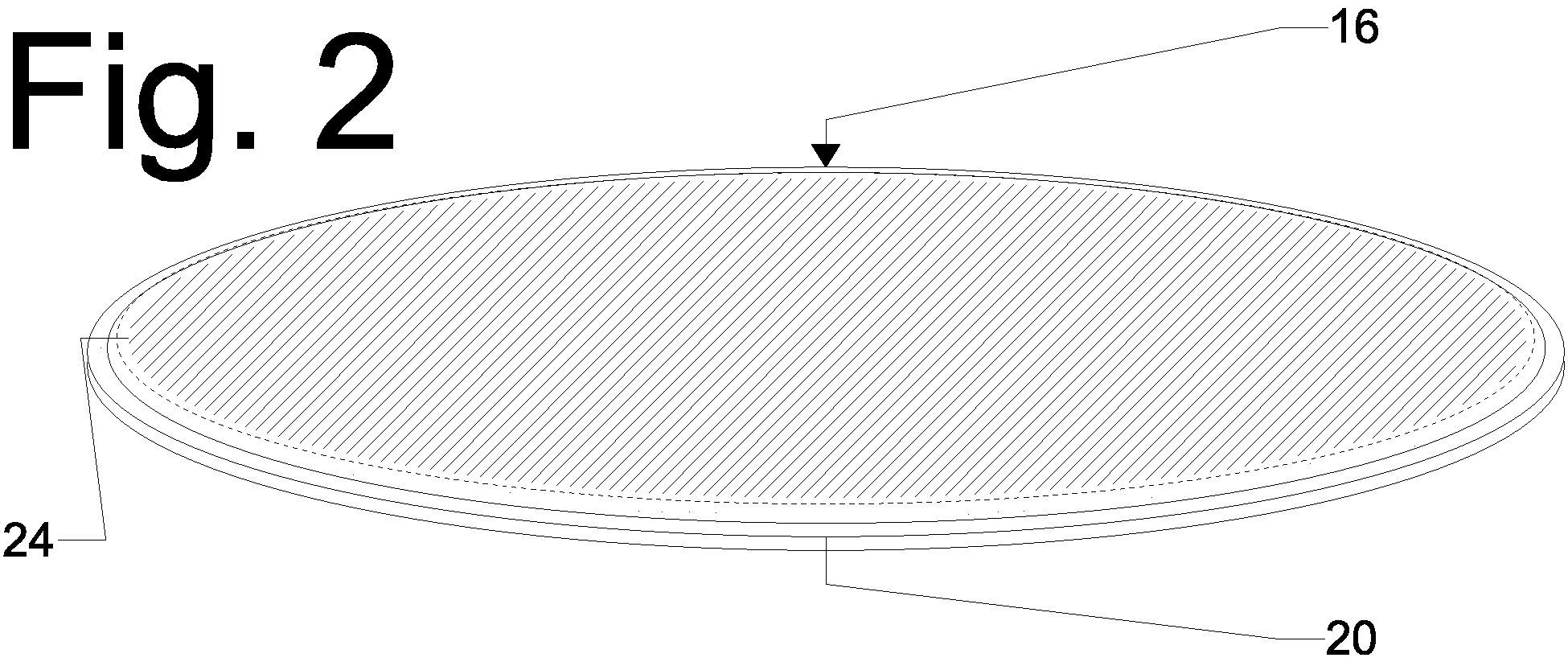

[0031]FIG. 2 depicts a perspective view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com