Screw jack for structures for easily adjusting its angle

a technology of screw jack and structure, which is applied in the field of screw jack, can solve the problems of limiting the usefulness of the screw jack to provide bracing or other angular support to excavated earthen or structural steel shapes, difficult task to perform quickly and accurately, and time-consuming and unwelcome tasks, so as to reduce the number of working processes, facilitate the adjustment, and enhance the effect of working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

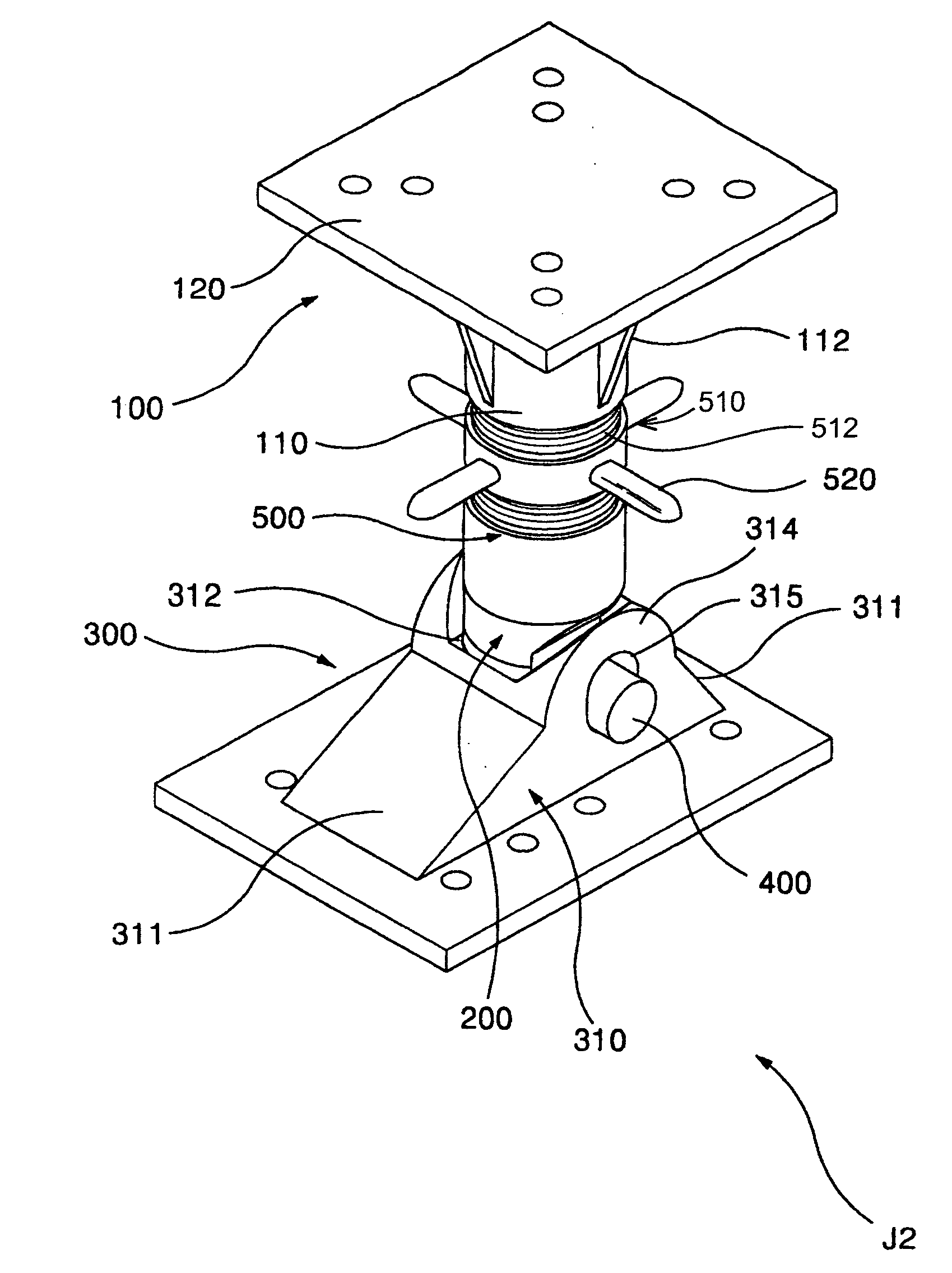

[0041]FIGS.9, 10, 11, 12 and13 collectively provide perspective and elevation views illustrating a structural screw jack capable of easily accommodating adjustment of its angle of inclination, constructed as the present invention.

[0042] As shown in FIGS.9 through 13, screw jack J2, when constructed as a second embodiment of the present invention has the same overall as the configuration of screw jack J1 in accordance with the first embodiment of the present invention, as shown in FIGS. 5 to 8. More specifically, screw jack J2 is constructed with an upper jack 100, a lower coupling shaft 200, a lower jack 300, and a steel pin 400.

[0043] Upper jack 100 may be constructed with upper coupling pipe 110 having a plurality of reinforcing ribs 112 formed on the outer side surface thereof, and an upper holder 120 closely coupled to the outer side surface of upper coupling pipe 110. Upper holder 120 may be shaped as a plate.

[0044] Lower coupling shaft 200 maybe shaped as a bar. One end of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com