Hydrogel for use in downhole seal applications

a technology of hydrogel and seal body, which is applied in the direction of sealing/packing, other chemical processes, borehole/well accessories, etc., can solve the problems of water starting to absorb and swell, and achieve the effect of preventing seal failure and high swelling for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Packer Elements

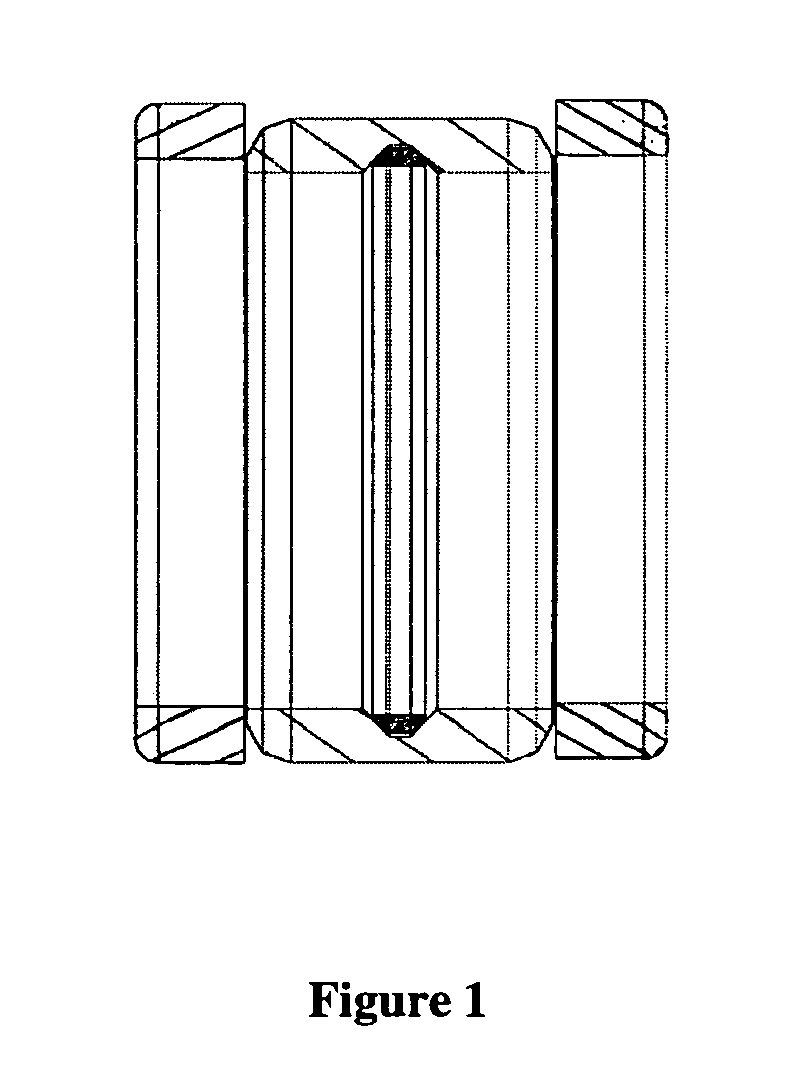

[0030]FIG. 1 shows three-piece rubber element array or packer element 10, such as that commonly used in downhole packers. The packer elements are external packer seal bodies that seal the annulus space between tubing and casing (not shown). Elements are energized by axial deflection of the seal bodies after the packer is run into the hole. Commonly used packer elements typically consist of backup end rings 16 and a center seal or element 18. The center seal 18 typically includes a ring 20 which establishes the inner diameter of the seal. Hydrogel may be included or incorporated into any or all of the seal body elements. The hydrogel allows the seal bodies to be energized in response to external stimuli, as previously described.

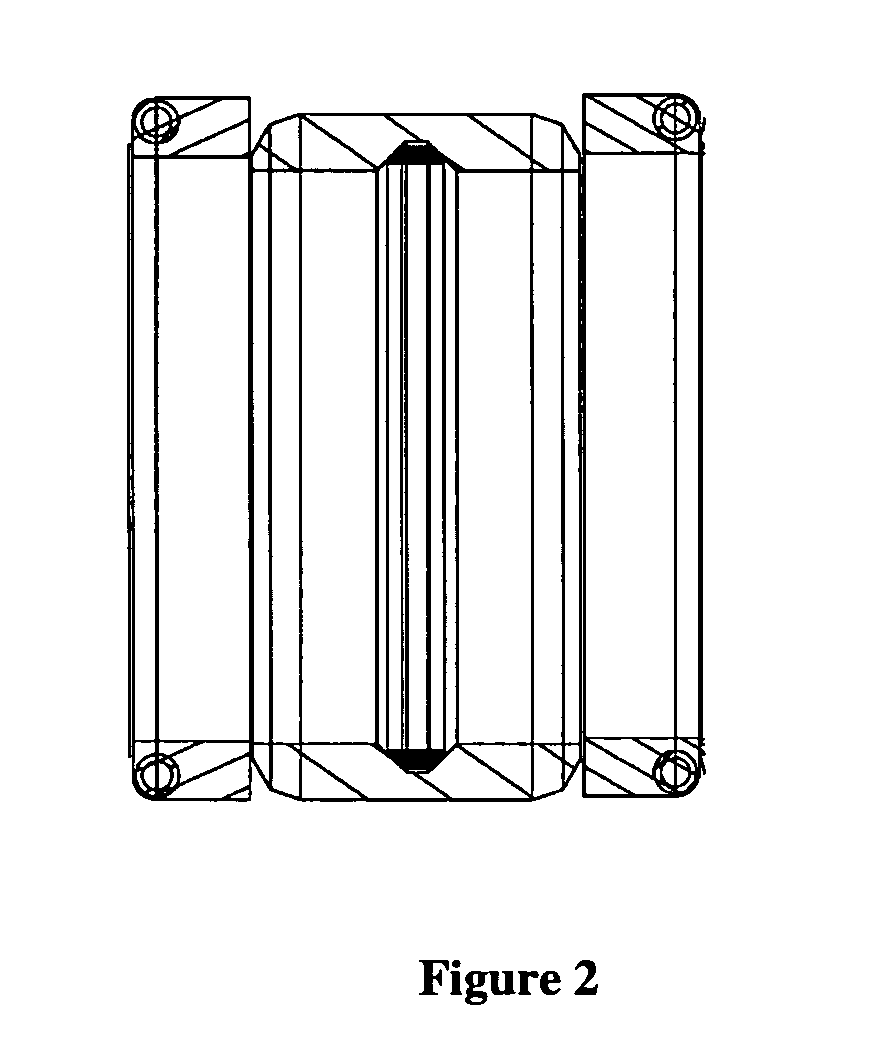

[0031]FIG. 2 shows a garter spring element array 50. The array 50 includes a main element or seal body 52, a garter spring 54 and backup end rings 56. The array also includes an ID ring 58. Hydrogel may be included in any or all of the seal b...

example 2

O-Ring

[0033] O-rings are simple bi-directional static seal bodies. For high temperature and / or high pressure sealing applications, backup rings are used to prevent O-ring extrusion. As shown in FIG. 4, the o-ring 150 includes two backup rings 152 which are formed of thermoplastic materials blended with hydrogel polymer. The O-ring may also be formed of elastomers blended with hydrogel polymer. In this application, the hydrogel is able to seal off potential leak paths as well as keep the o-ring energized via swelling. These characteristics are not achievable with existing conventional rubber materials used for o-ring applications.

example 3

T-Seal Bodies

[0034] T-seal bodies are typically used as reciprocating bi-directional dynamic seals. As shown in FIG. 5, T-seal 200 including seal body 202 and retaining ring 204. The seal body is formed of a hydrogel modified thermoplastic or elastomer. Hydrogel can seal off potential leak paths as well as keep the T-seal energized via swelling. These benefits are not achievable with existing conventional rubber materials used for T-seal application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| sealing forces | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com