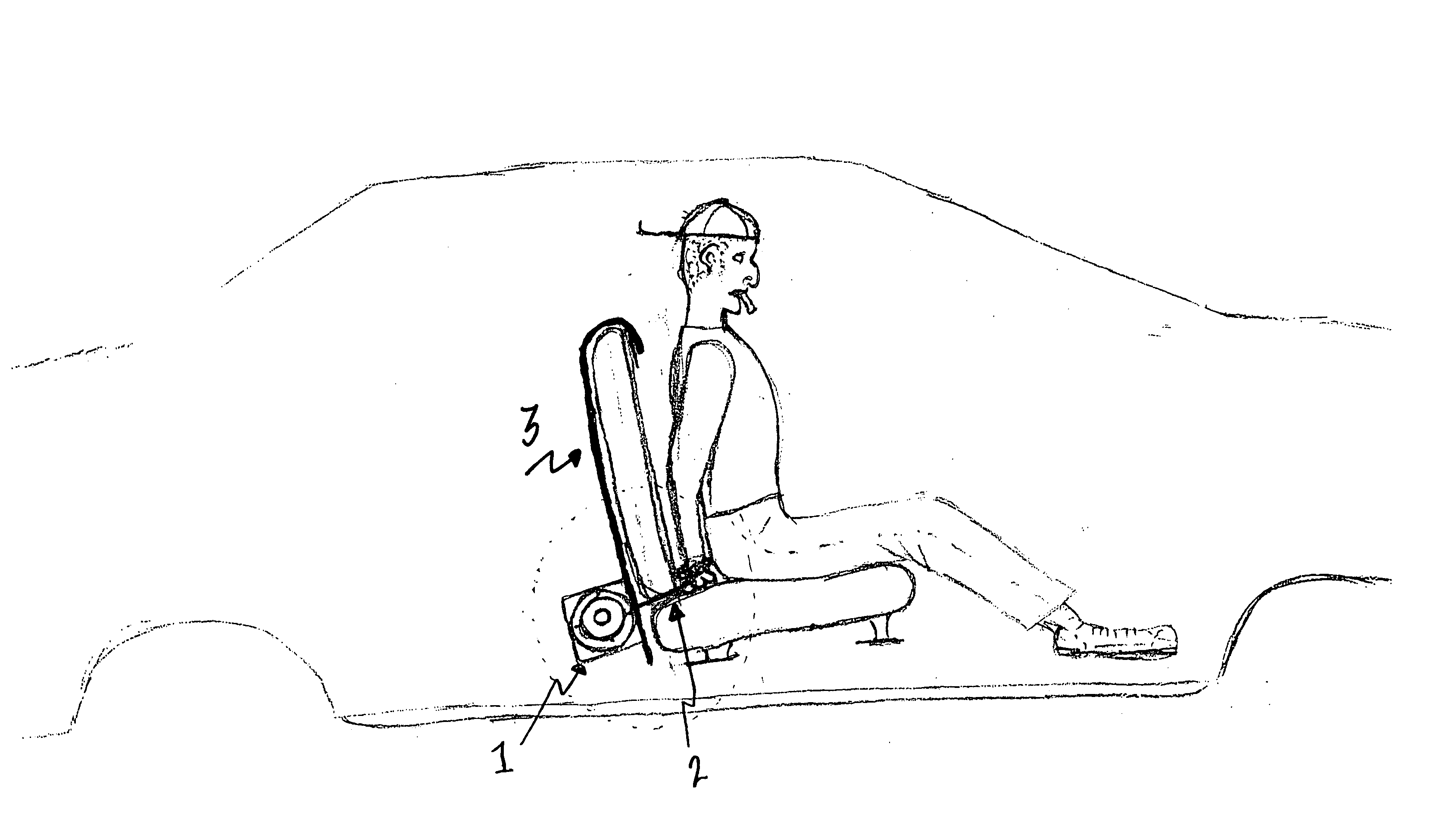

Prisoner seat security device

a security device and seat technology, applied in the field of prisoner seats, can solve the problems of preventing the ability of officers to assault officers or operate police vehicles, and achieve the effects of low profile, increased vehicle resale value, and low profile design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

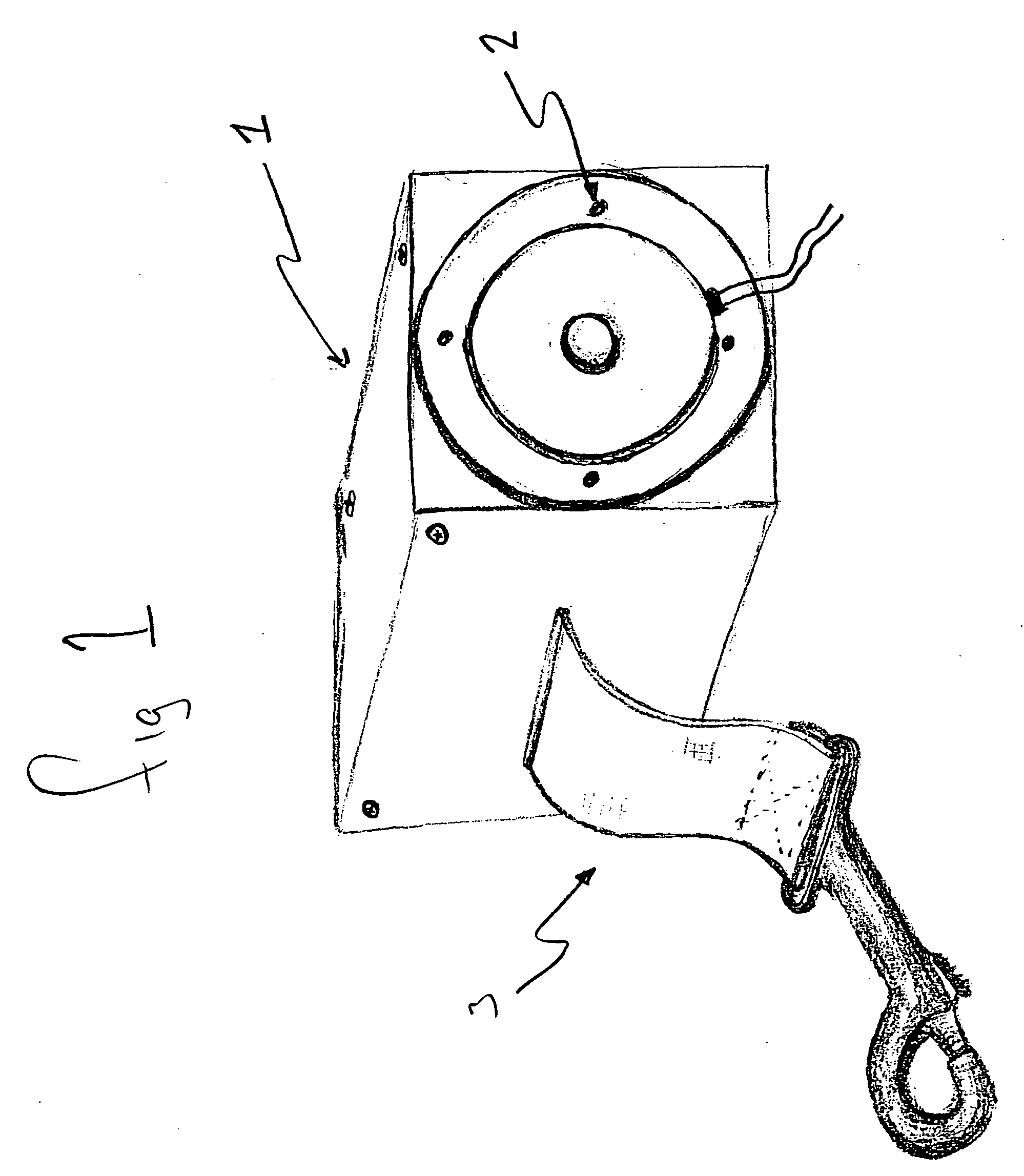

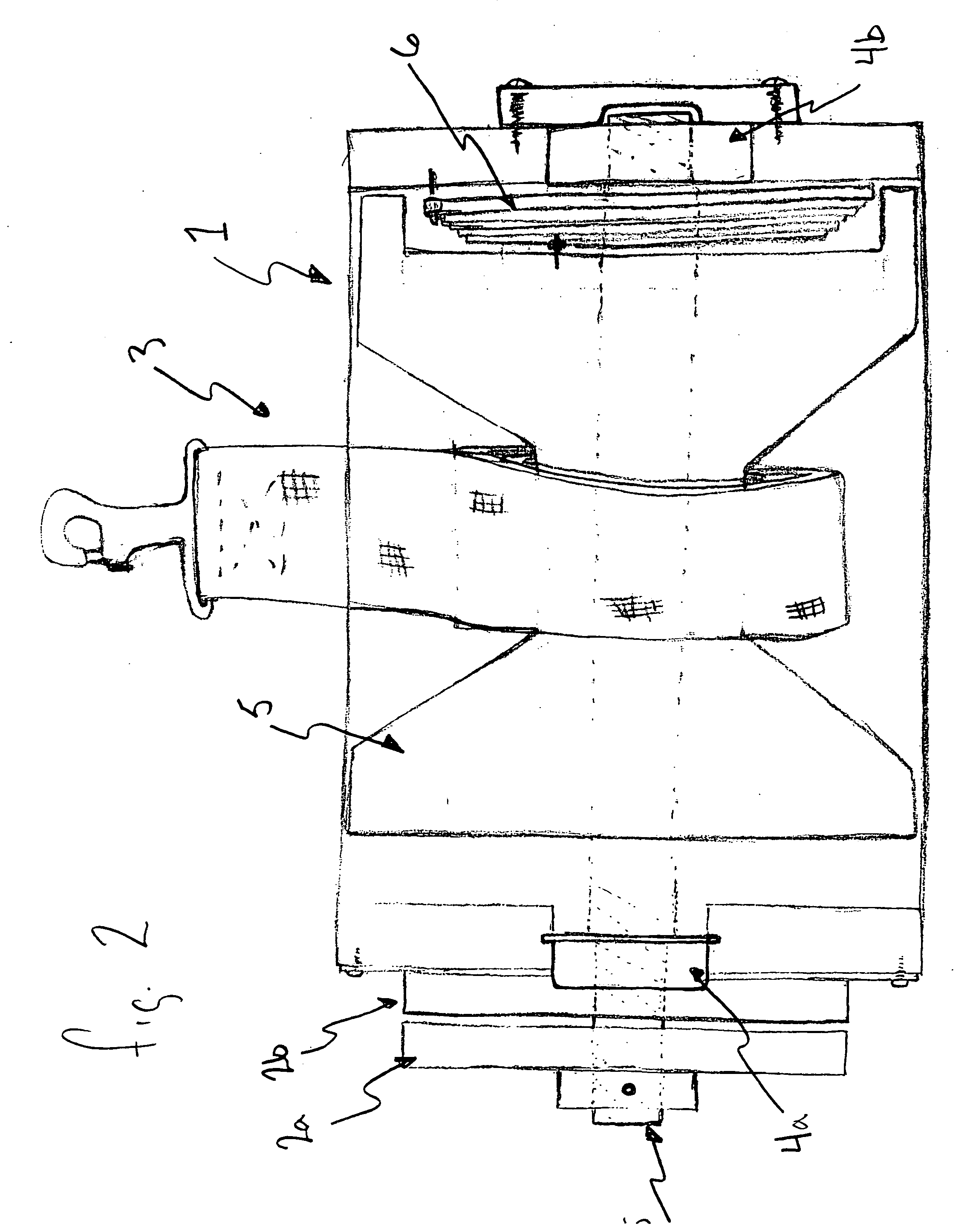

[0022] The retractable restraint device as shown in FIG. 2 consists of a case assembly (FIG. 2(1)); electromagnetic brake (FIG. 2(2a, b)); strap assembly (FIG. 2(3)); sealed bearing assemblies (FIG. 2(4a, b)); shaft and spool assembly (FIG. 2(5)); return spring (FIG. 2(6)); and restraint strap (FIG. 2(3)).

[0023] The free end of the restraint strap (FIG. 2(3)) is allowed to pass from the case assembly (FIG. 2(1)) through an opening cut into the case assembly (FIG. 2(1)). The free end of the restraint strap (FIG. 2(3)) is intended to have a clasp or hook to attach to the restrained prisoner's handcuffs.

[0024] The restraint strap (FIG. 2(3)) is wound on the shaft and spool assembly (FIG. 2(5)) which is kept in a state of tension by return spring (FIG. 2(6)). This provides for the retraction of the restraint strap (FIG. 2(3)) when the invention is in the inactive mode. The shaft and spool assembly rides on the two bearing assemblies (FIG. 2(4a, b)) to allow free movement of the shaft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com