Modular kayak with elevated hull voids

a module and hull technology, applied in the field of siton-top kayaks, can solve the problems of no prior art, increased manufacturing costs, and leakage of moulds and possible holes in the seam of scuppers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

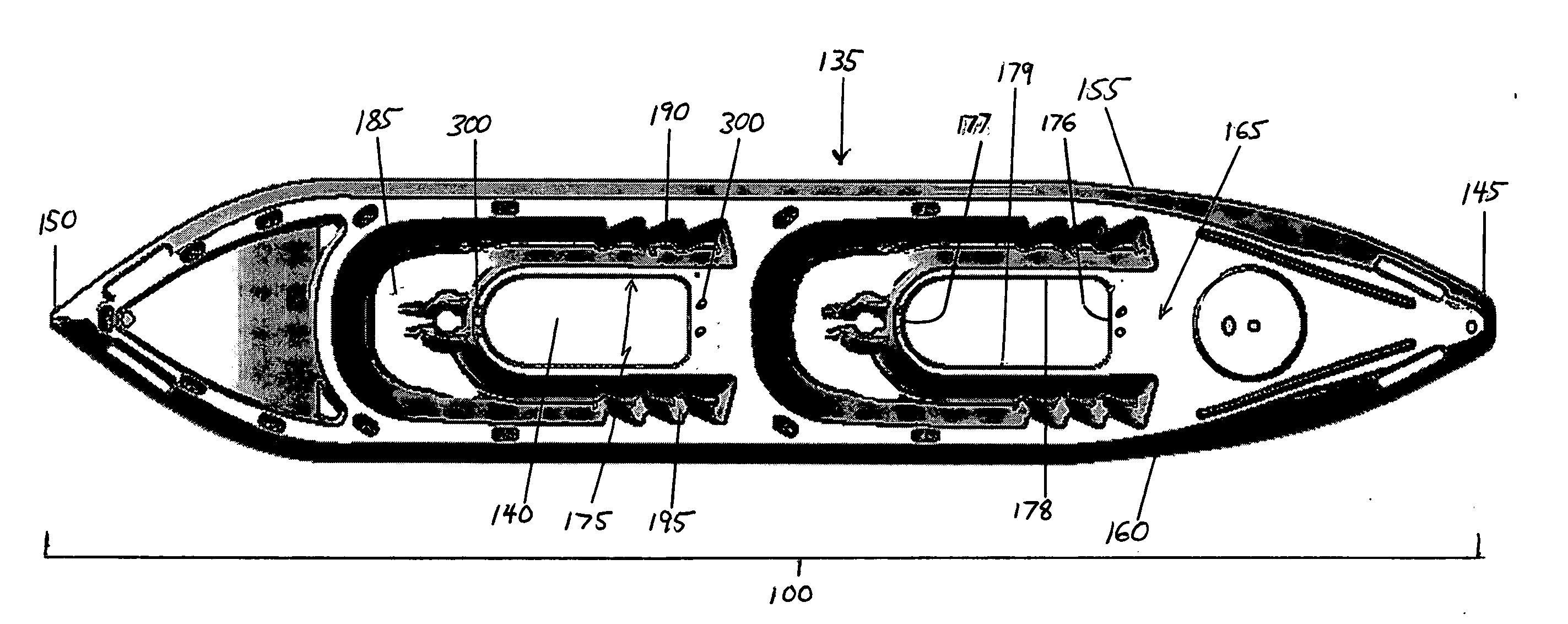

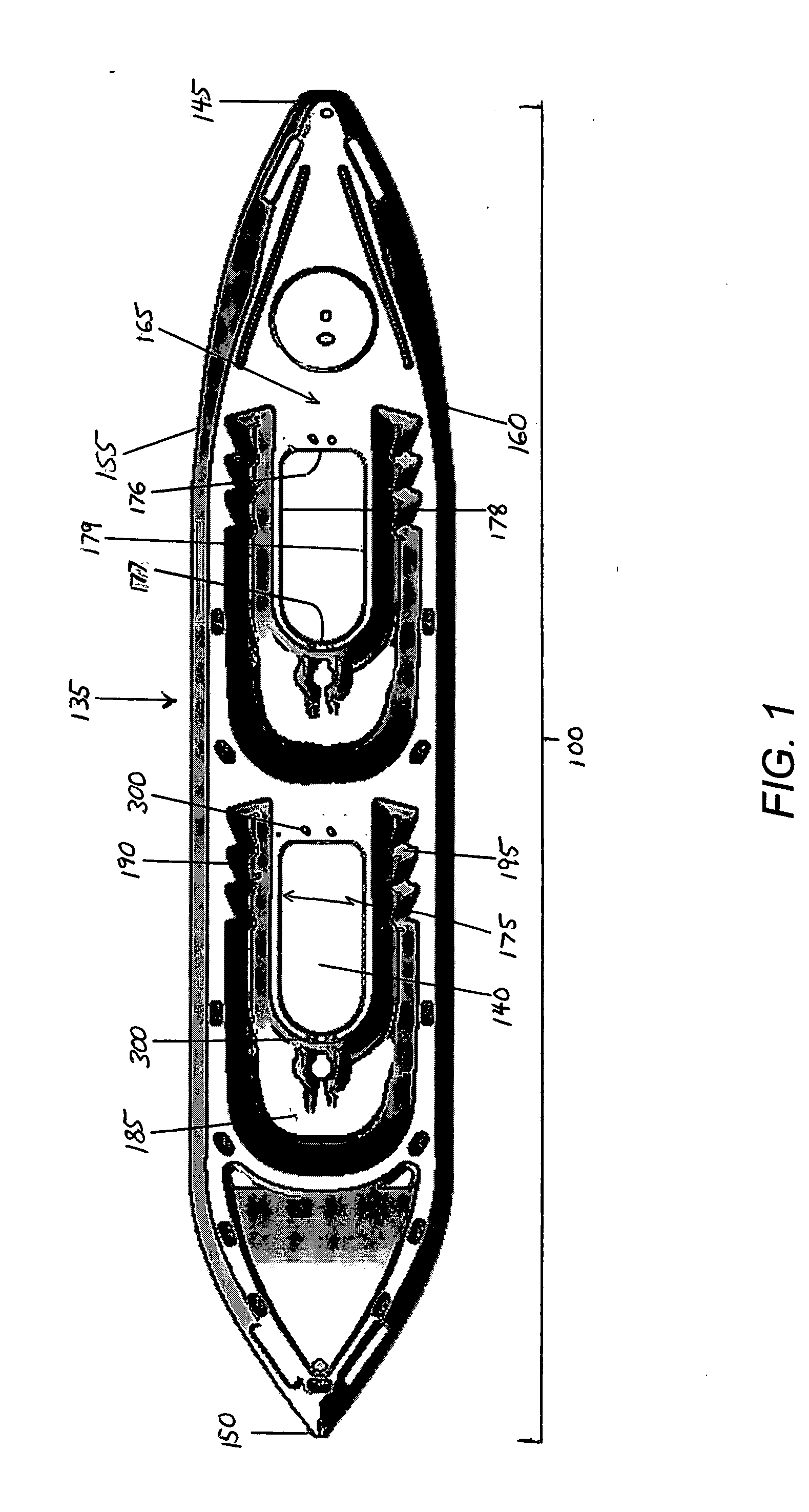

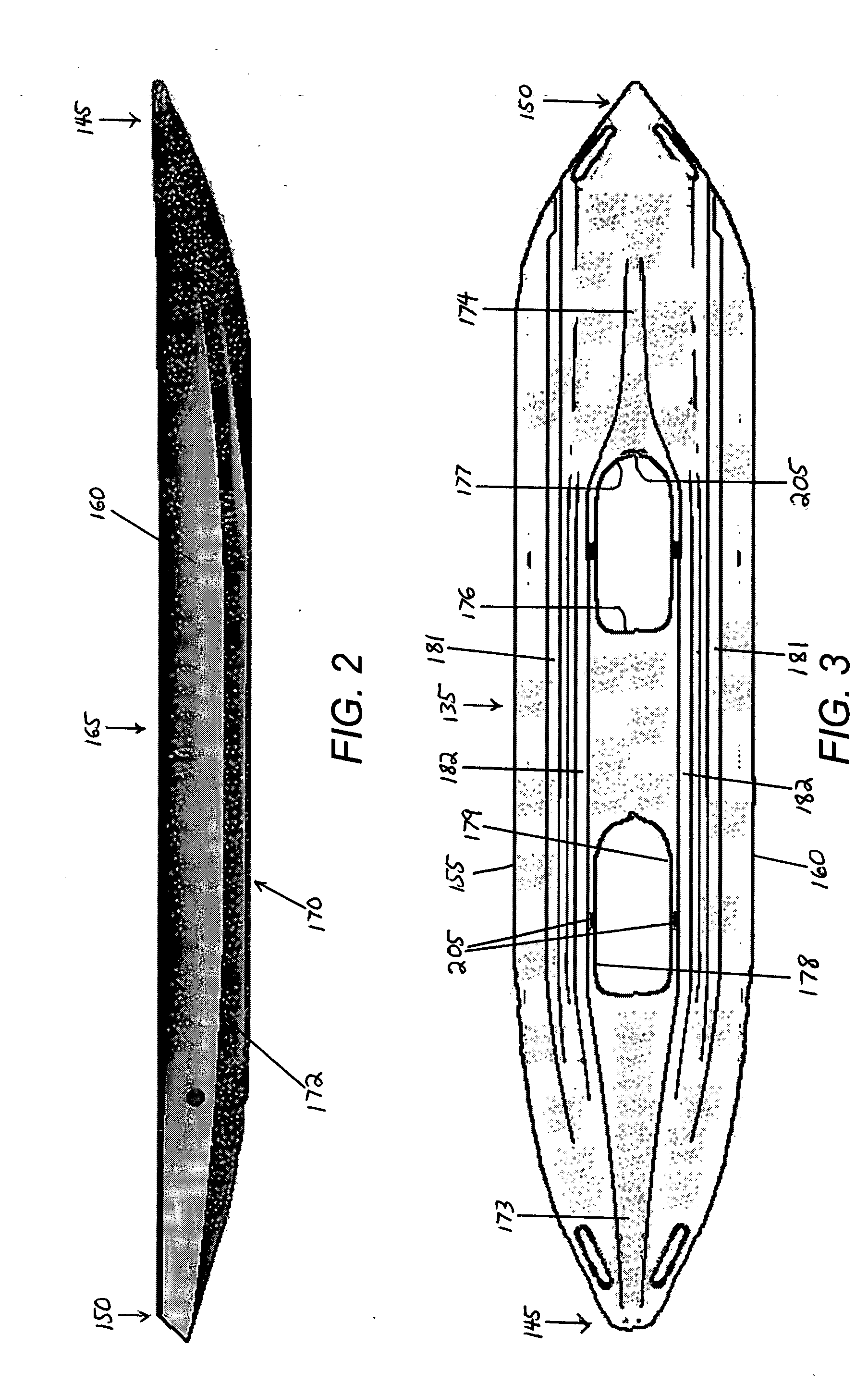

[0032] Referring initially to FIGS. 1-3 of the drawings, depicted at 100 is the modular kayak with elevated hull voids, constructed in accordance with, and embodying, the principles of the present invention, The surrounding hull 135 has an outer surface defining a bow end 145 and a stern end 150 and a port side 155 and a starboard side 160 and a top surface 165 and a bottom surface 170 separated by a parting line 172 extending around the perimeter of the surrounding hull 135. The surrounding hull 135 further comprises primary interior walls 175 defining a first end 176 and a second end 177 as well as a first side 178 and a second side 179.

[0033] Referring now to FIGS. 1-7 of the drawings, depicted are various views and elements of the modular kayak with elevated hull voids, constructed in accordance with, and embodying, the principles of the present invention.

[0034] The cockpit 180 is a recess within the top surface of the surrounding hull 135. The cockpit 180 comprises a seating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com