Integral add heat and surge control valve for compressor

a compressor and control valve technology, applied in the field of compressors, can solve the problems of reducing thermodynamic performance, damage to the compressor, damage to the bearing and support structure of the compressor, etc., and achieves the effects of preventing deicing, rapid response time, and preventing surg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

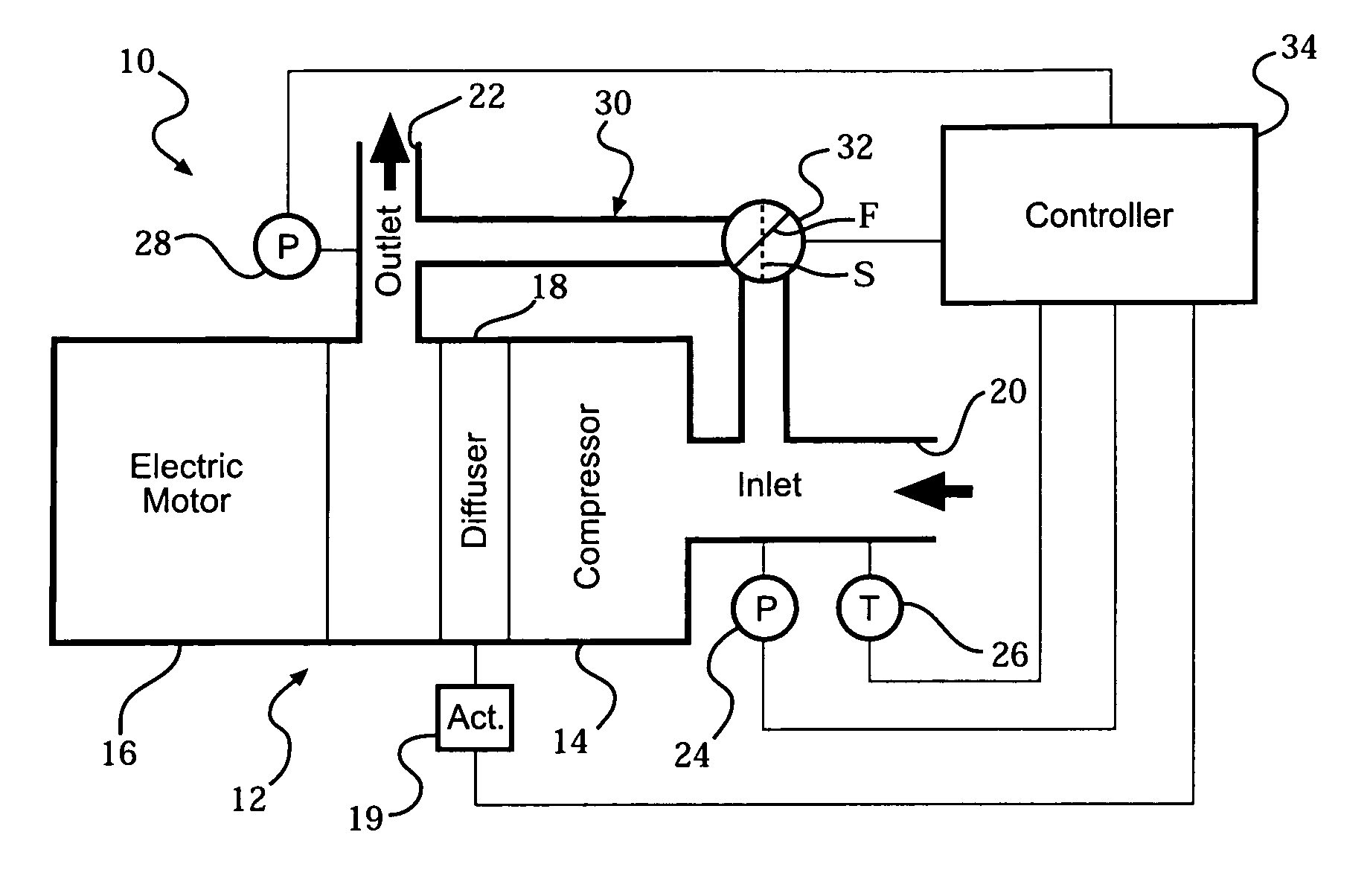

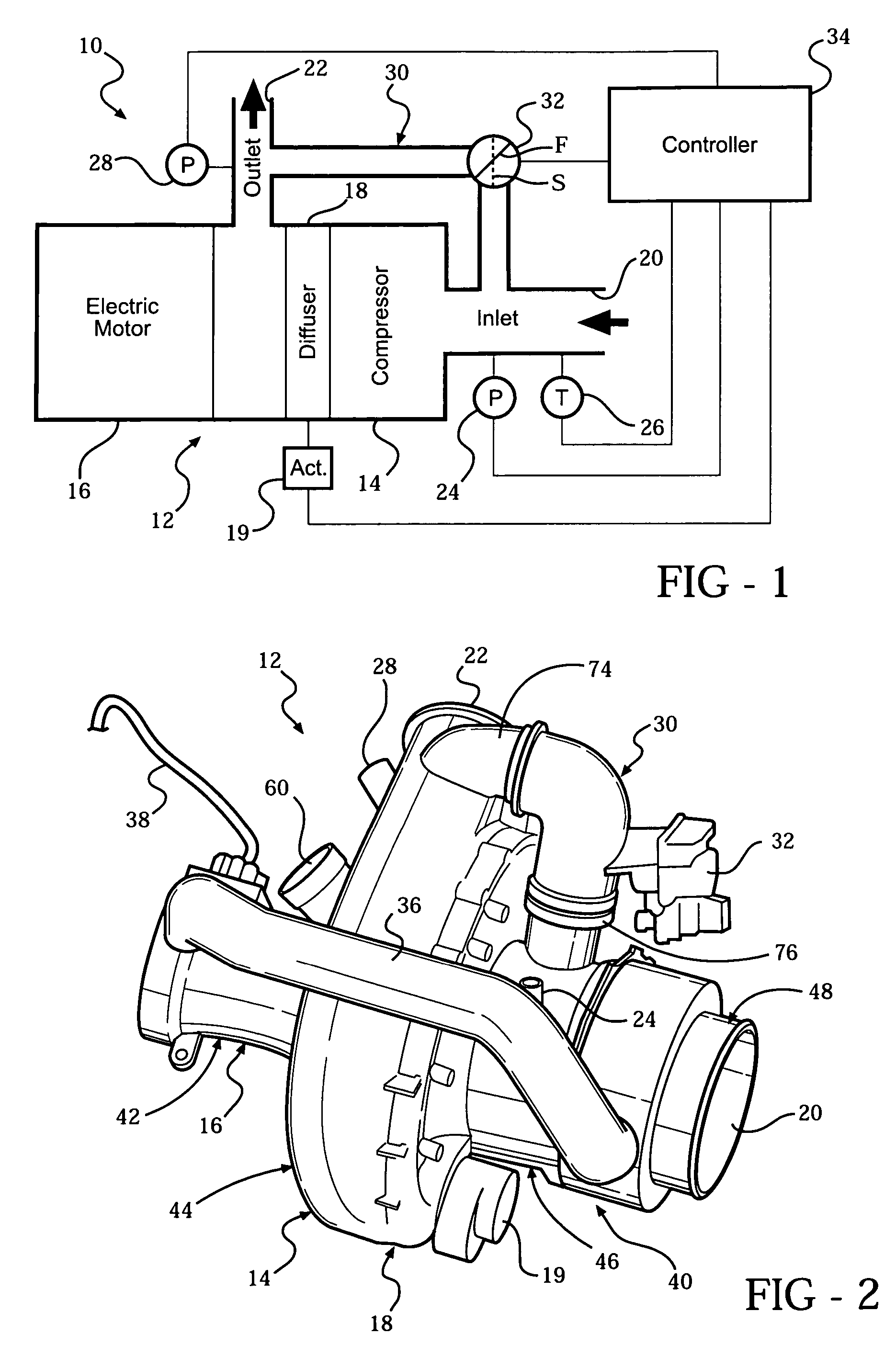

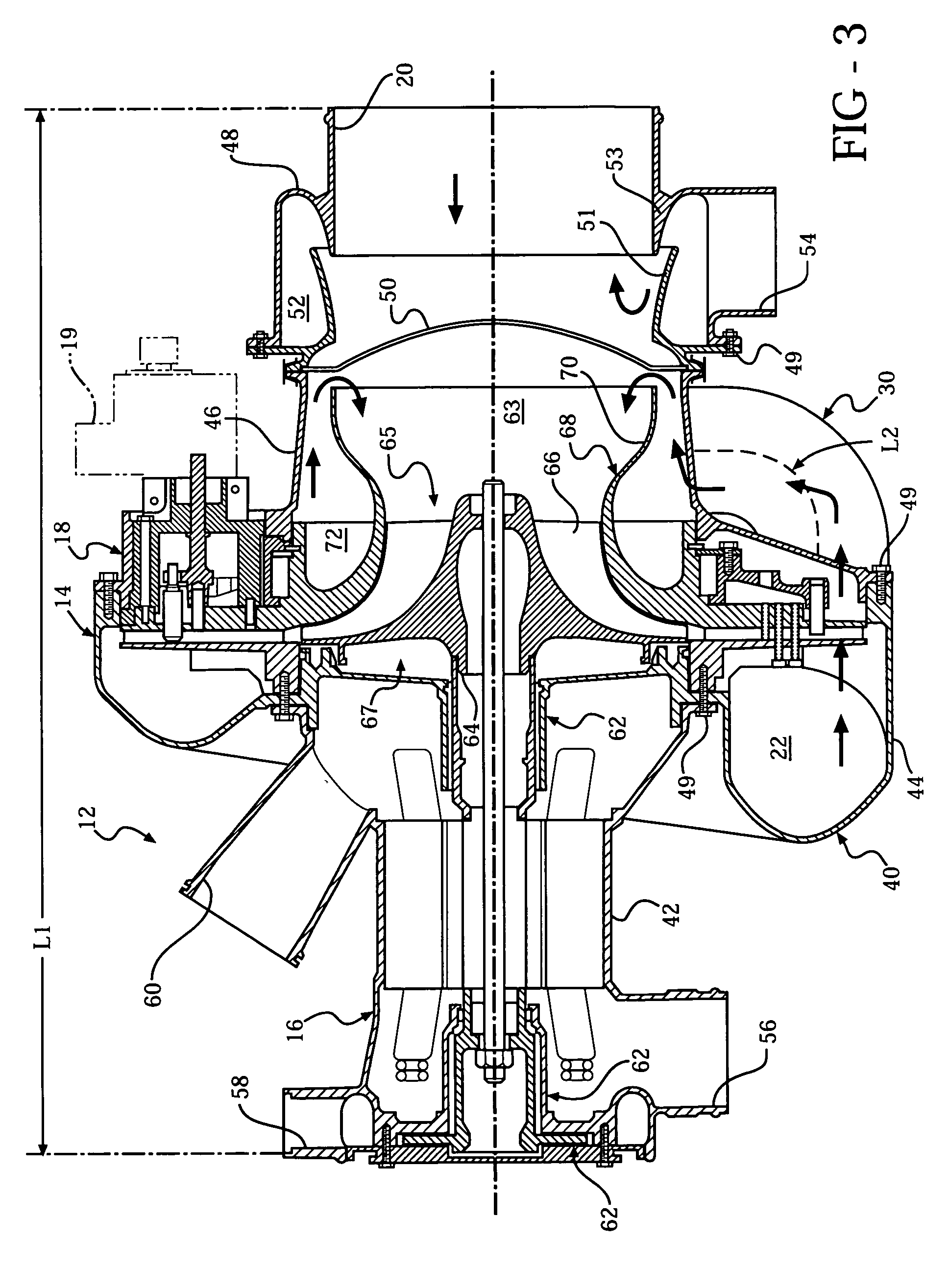

[0013] A compressed air system is shown schematically at 10 in FIG. 1. The compressed air system 10 includes a compressed air unit 12 comprising a compressor 14 driven by an electric motor 16. A diffuser 18 is arranged before an outlet 22 of the compressor 14, as is known in the art. The diffuser 18 is manipulated by an actuator 19 to vary its area. Air enters the compressor 14 through an inlet 20. Pressure and temperature inlet sensors 24 and 26 are arranged at the inlet 20, and a pressure outlet sensor 28 is arranged at the outlet 22. The actuator 19 and sensors 24, 26 and 28 are schematically shown in communication with a controller 34. The controller 34 uses the sensors 24, 26 and 28 to determine surge and add-heat conditions. The compressed air system 10 described above is suitable for providing, for example, compressed air to an air cycle machine for producing conditioned cabin air.

[0014] The present invention utilizes a duct 30 to fluidly connect the inlet 20 and outlet 22. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com