Multi-stage turbocharging system utilizing VTG turbine stage(s)

a turbocharger and multi-stage technology, applied in the direction of charge feed system, non-fuel substance addition to fuel, combustion engine, etc., can solve the problems of turbocharger performance decline, turbocharger has a tendency to “overspeed”, and loss of efficiency, etc., to achieve significant benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

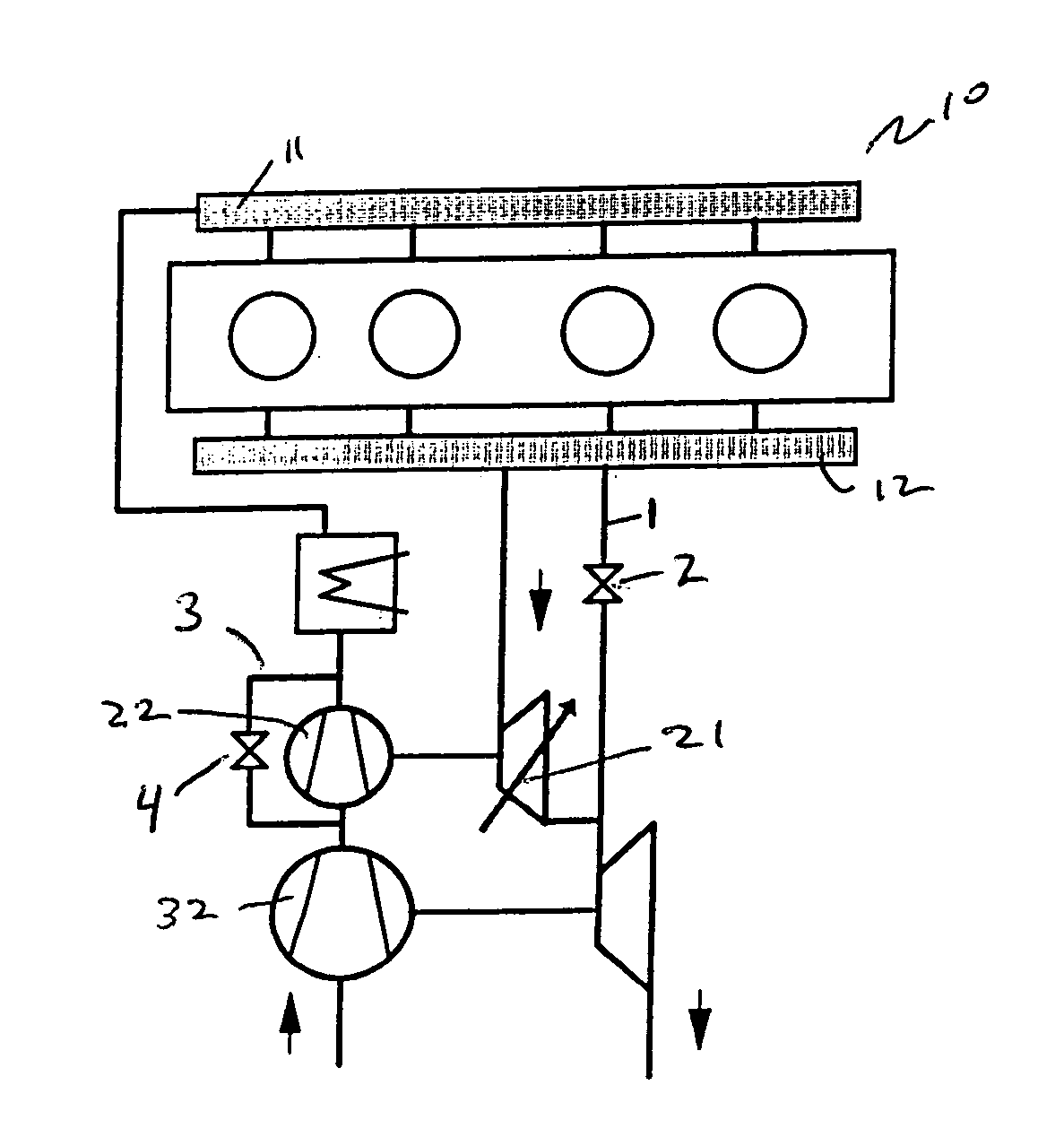

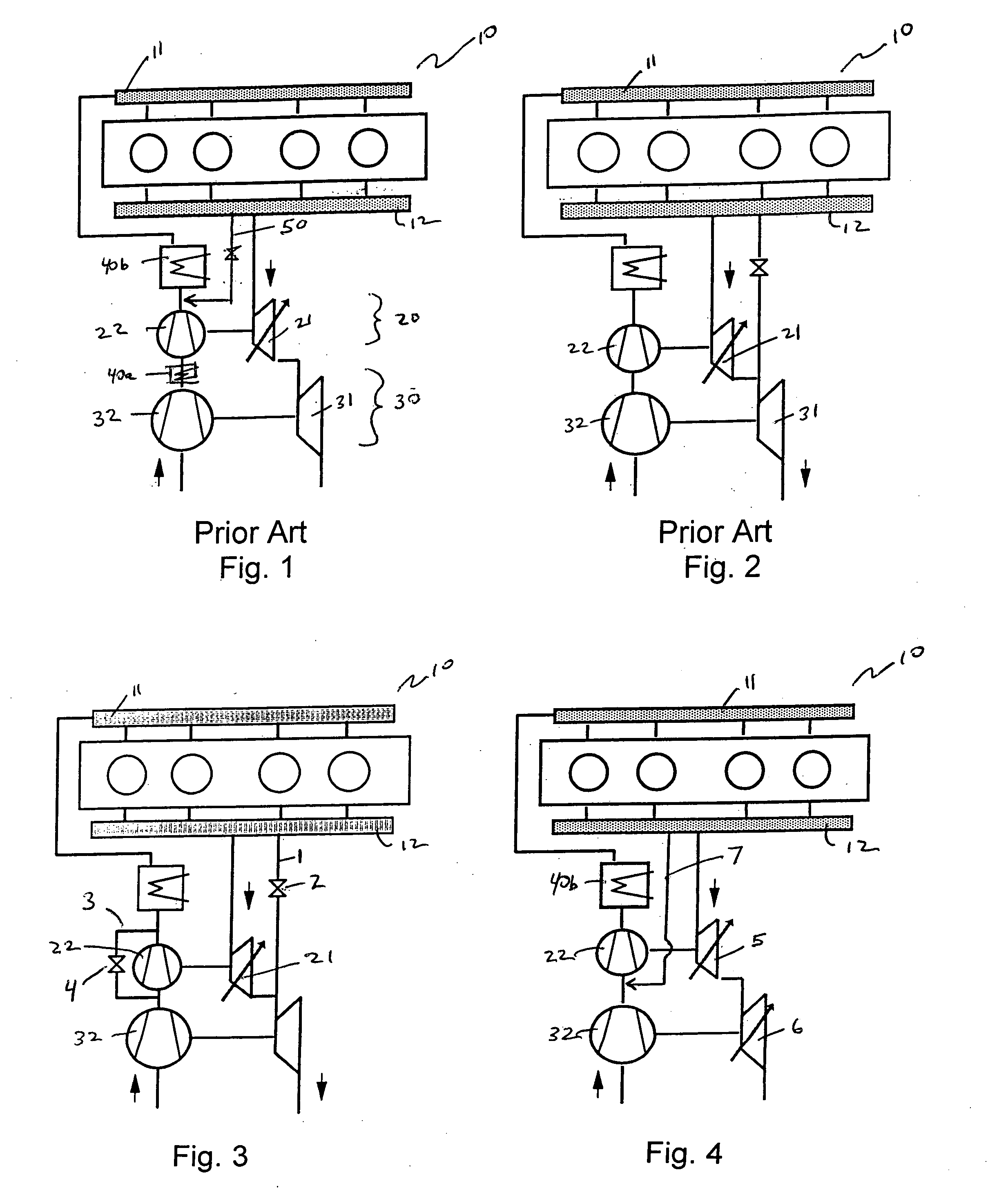

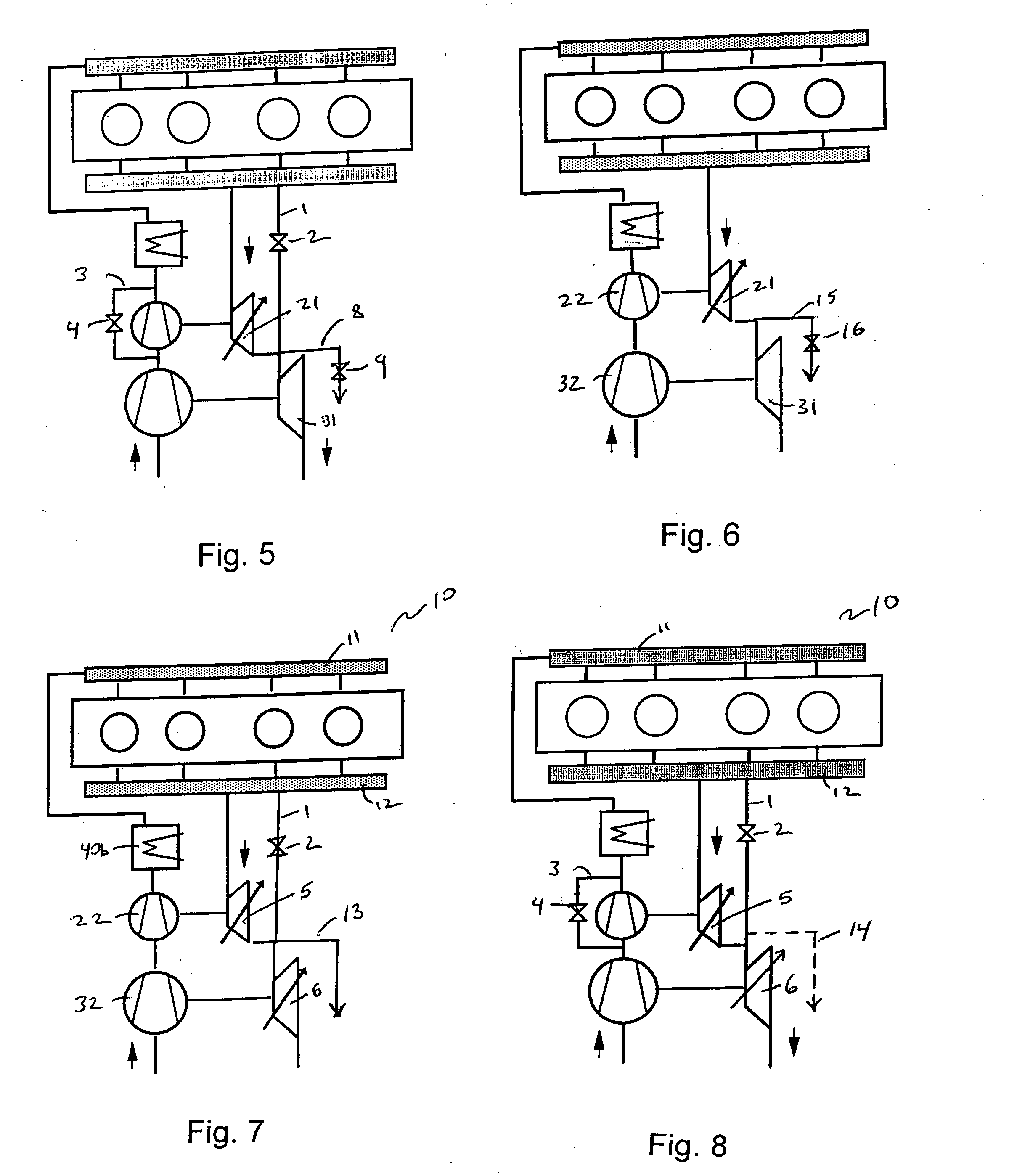

[0059] Turning now to the present invention, according to the invention as shown in FIG. 3, the inventors discovered that significant benefits could be obtained by providing the variable regulated two stage turbocharger (VR2S) shown in FIG. 2 with a HP compressor bypass (hereafter VR2S-CB) comprising bypass pipe 3 and pipe switch 4. More complex than the VR2S, this design allows both the HP turbine and the HP compressor to be bypassed, such that the system could in effect, at high exhaust gas flow low power (e.g., maintaining high speed on a level highway), simply operate as an efficient single stage compressor, with large LP turbine and large LP compressor. The HP compressor, being bypassed, does not impede flow of air from the LP compressor to the engine. At the same time, since the HP stage is allowed to “idle”, it allows the HP stage to quickly increase RPM, thus provide rapid transient response, when acceleration is required for passing or when power is required for climbing.

[0...

fourth embodiment

[0062] According to the invention, the inventors discovered that significant benefits could be obtained by providing a V2S with a LP turbine bypass pipe 15 and pipe switch 16 (hereafter V2S-LTB).

fifth embodiment

[0063] According to the invention, the inventors discovered that significant benefits could be obtained by providing a DV2S with a HP turbine bypass pipe 1 and switch 2 (thus making the system “regulated”) and with a LP turbine bypass 13 (hereafter DVR2S-LTB).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com