Fixtureless vertical paddle electroplating cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

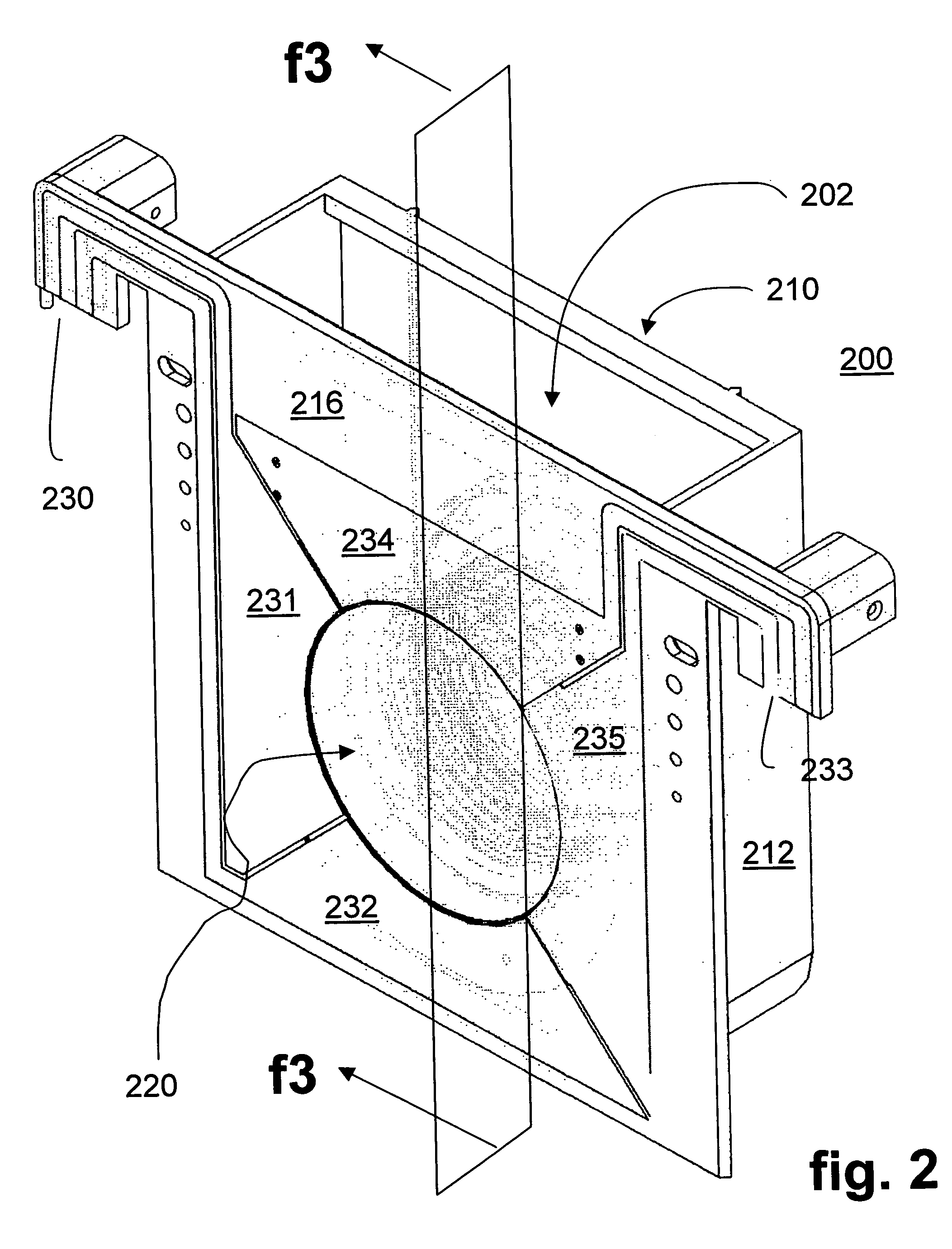

[0020] As discussed above, the present invention is directed to a fixture-less electroplating apparatus which facilitates easy insertion, positioning, and removal of a work-piece from an electroplating bath. The invention includes in one embodiment a submersible cathode compartment assembly serving as the “vehicle” for carrying the work-piece into the bath. Advantageously, the front surface of the work-piece is exposed to the bath, while the back surface of the work-piece is protected from exposure within the submersible compartment; and the technique for handling the work-piece can be implemented without any significant pre-fixturing of the work-piece, thus substantially increasing production throughput.

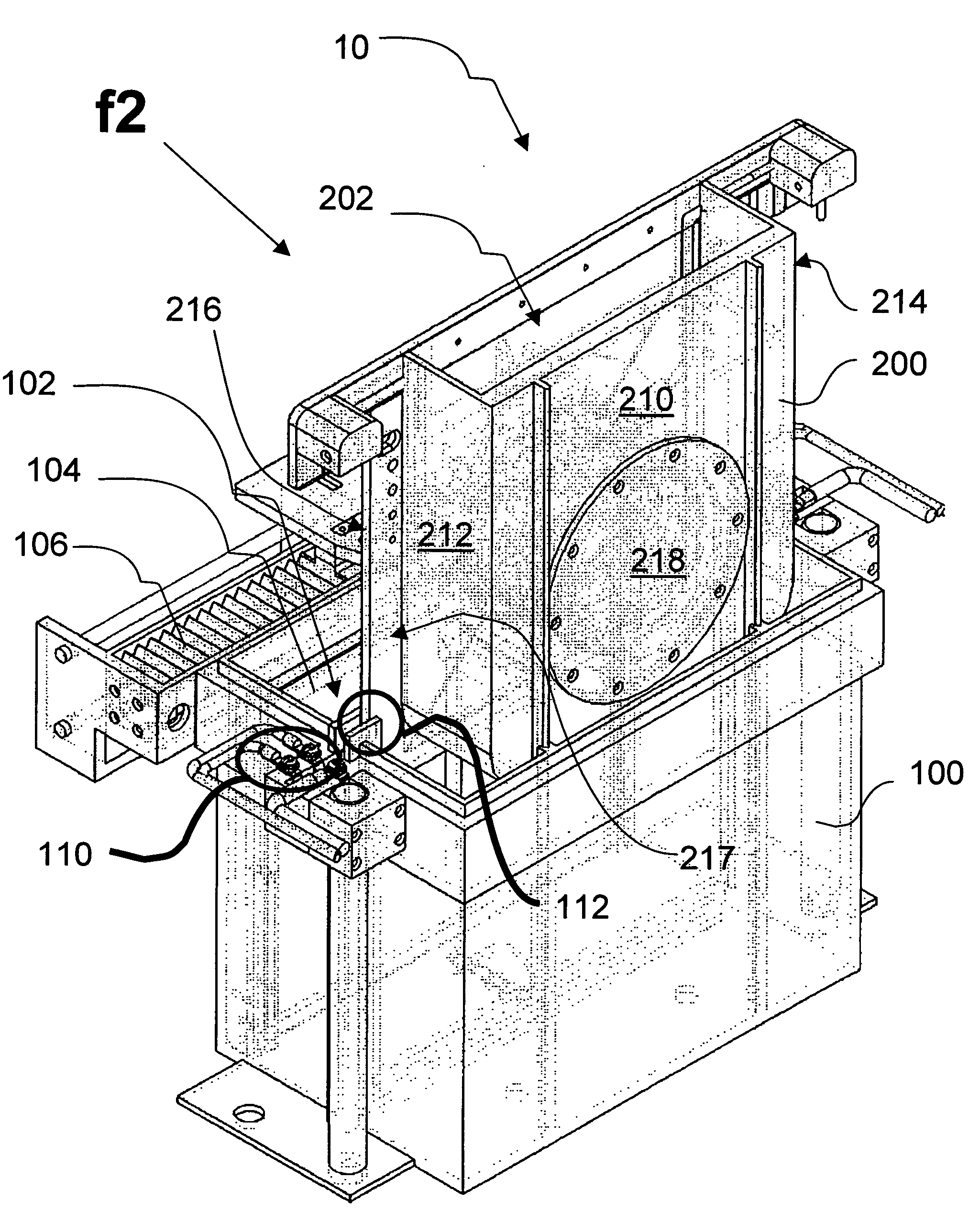

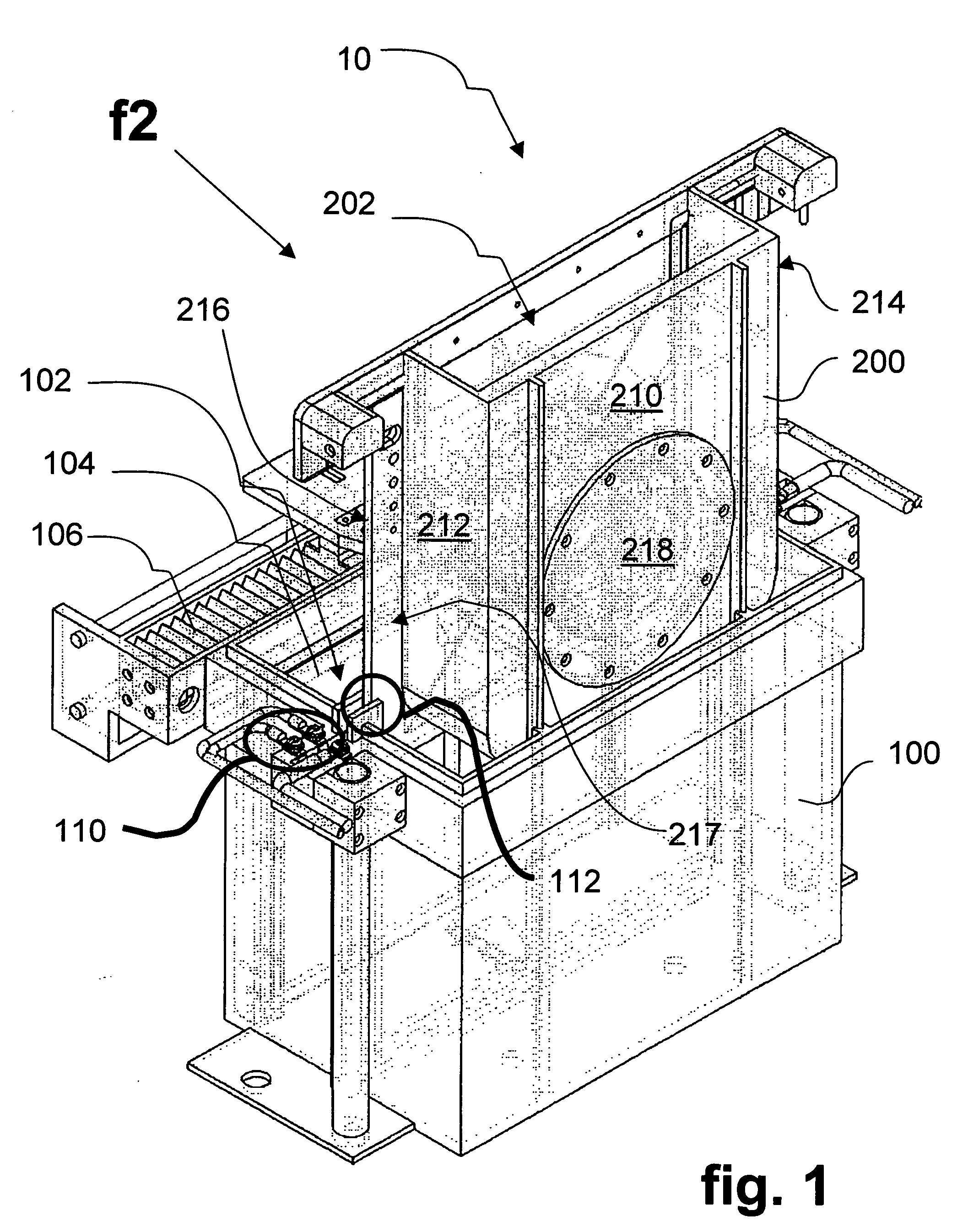

[0021] With reference to FIG. 1, electroplating assembly 10 includes a primary electroplating cell 100 containing the volume of electrolyte in its tank 102 and an anode 104 held in place within the tank, here vertically against one wall. The tank in one embodiment includes bottom, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com