Method and apparatus for controlling a variable speed fan in an image forming device

a variable speed fan and control method technology, applied in the direction of motor/generator/converter stopper, dynamo-electric converter control, instruments, etc., can solve the problems of large noise level and general low frequency of the “tach” signal in these low-cost fans, and provide enough information for a host devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

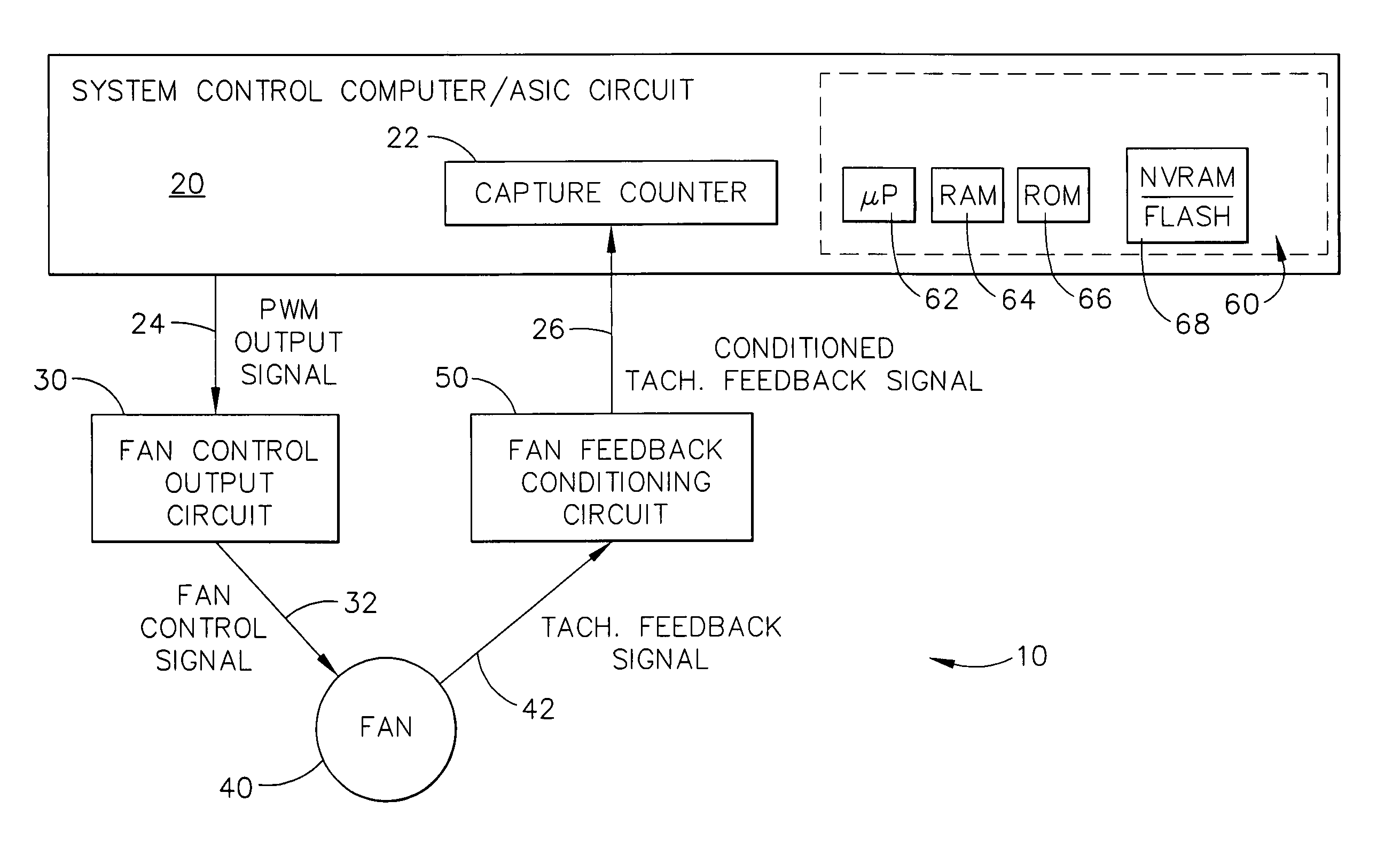

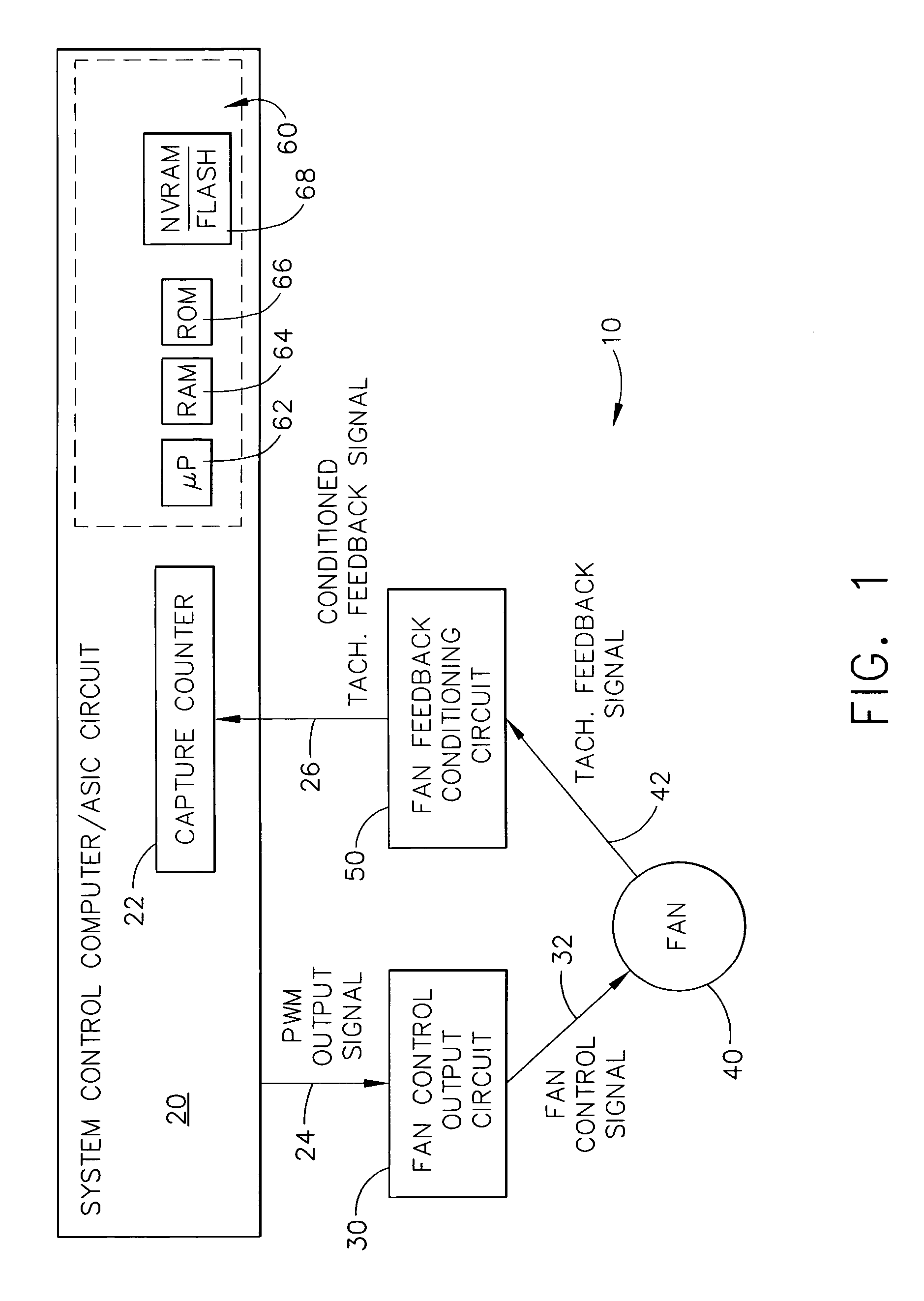

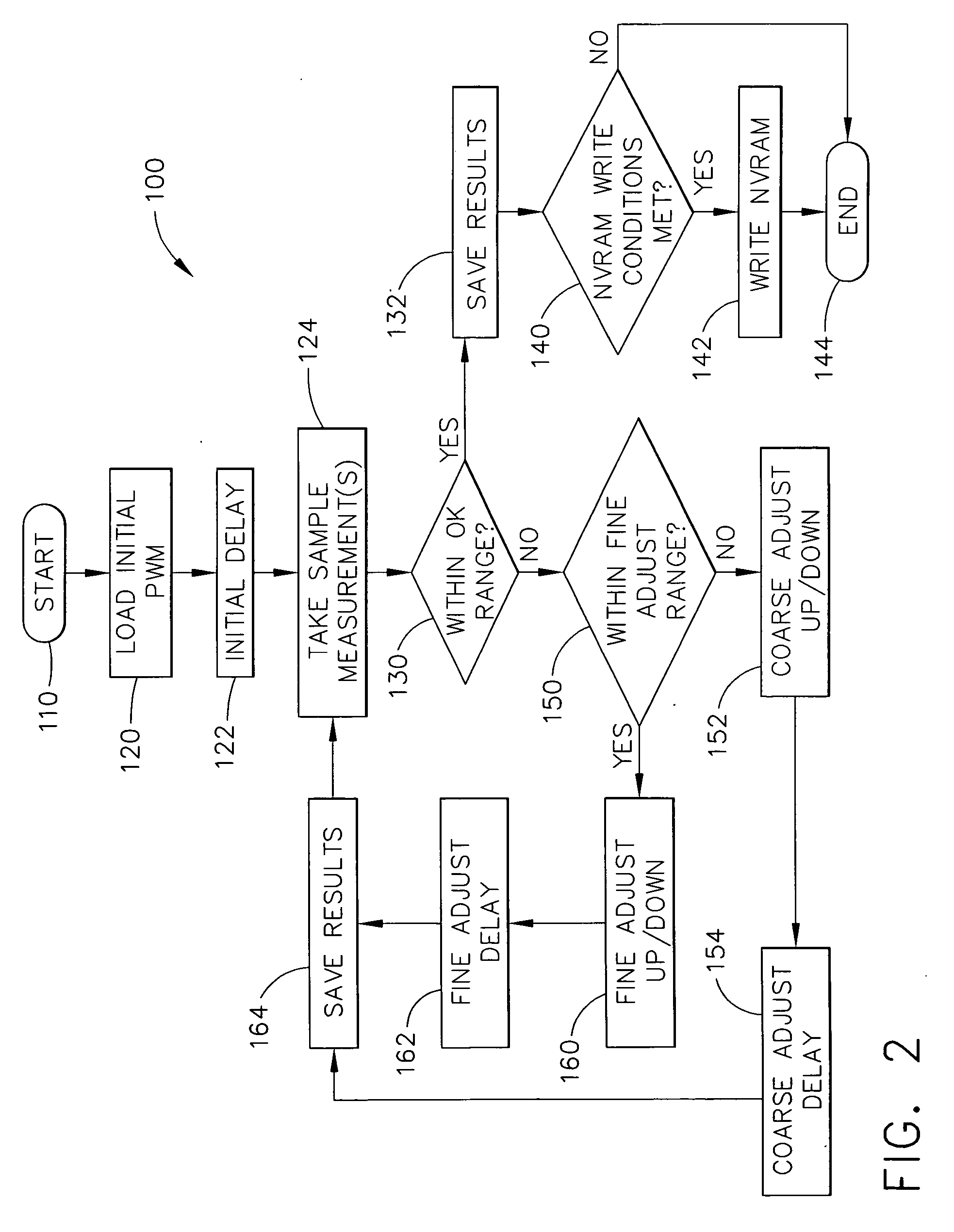

[0023] Reference will now be made in detail to the present preferred embodiment of the invention, an example of which is illustrated in the accompanying drawings, wherein like numerals indicate the same elements throughout the views.

[0024] As noted above, conventional control circuits and fan designs used in relatively inexpensive electrophotographic or “EP” printers (e.g., laser printers) may allow the possibility of a relatively wide variation in fan speed for a given output control signal from the controller, due to variation in manufacturing tolerances and other parameters. In addition, the fan's response to a received control input signal may be non-linear, due to either the fan's design or to its interaction with the host device's control circuitry. A given fan typically is assumed to operate consistently with itself over time within an assumed tolerance (although there can be some thermal drift), but it is desirable that fan-to-fan variation be minimized in the system. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com