Safety pneumatic tire for the biclycle

a pneumatic tire and safety technology, applied in the direction of tyre beads, without separate inflatable inserts, and with separate inflatable inserts, etc., can solve the problems of escaping through the broken hole of the inner tube, leaking compressed air inside the inner tube, and causing immediate deflation of the tire, and corresponding loss of stability of the bicycl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention is described in detail and refers to the drawings. The emphasis is on the structure of assembly, the technique and the achievement of the desired result.

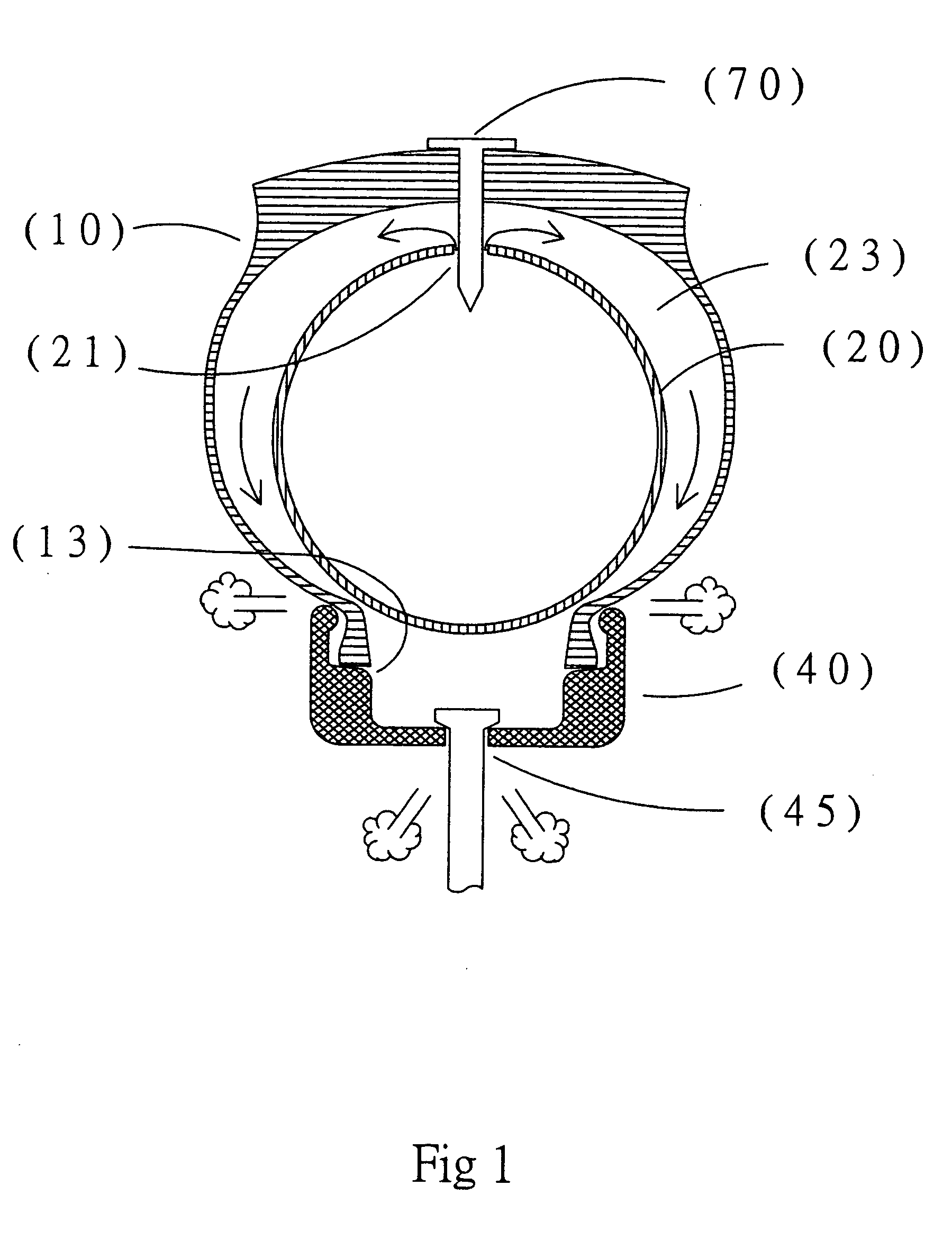

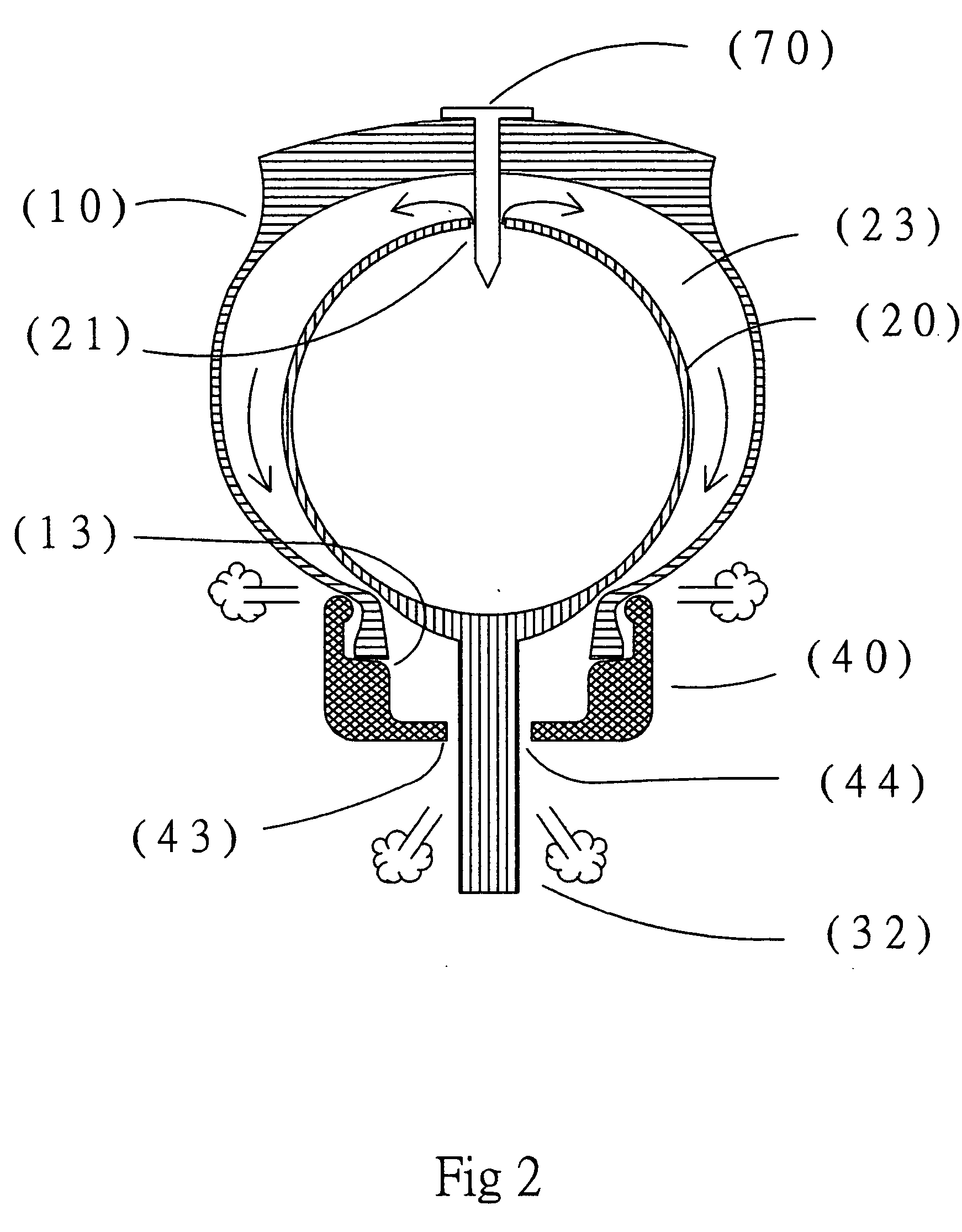

[0027] The function of the safety pneumatic tire is illustrated in FIGS. 3, 4 and 5.

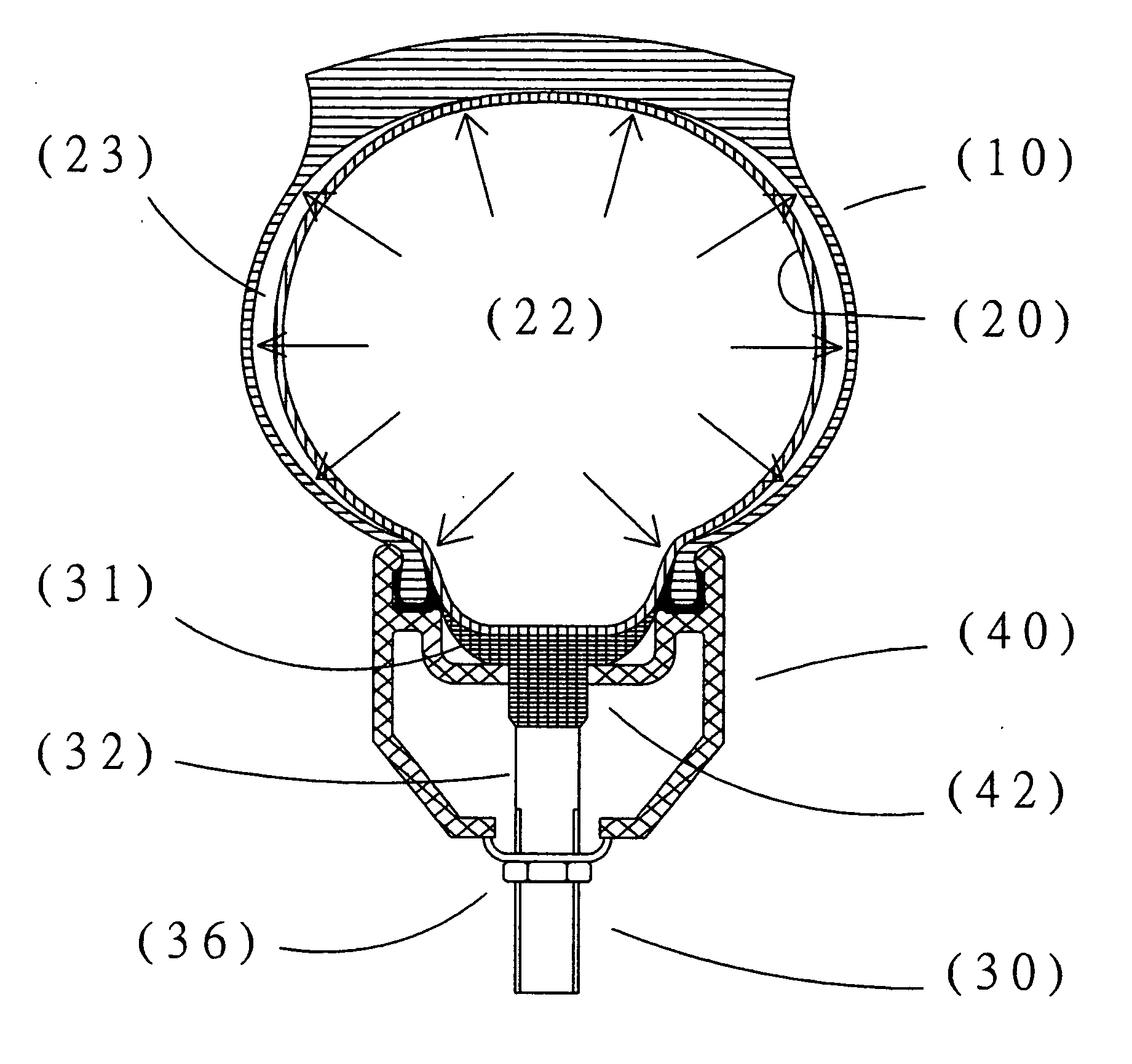

[0028]FIG. 3 displays all the parts that are to be assembled for the safety pneumatic tire. The improved tire (10) has beads (11) that are coated with an elastomeric layer (12). These coated beads (11) are mounted on the bead-seats (41) of the tubeless rim (40). The natural elasticity of the elastomeric material coating (12) naturally ensures a close contact of the tire beads with the rim bead seats (41), which forms an airtight chamber.

[0029] In addition, the elastic rubber-covered valve base (31) of the elastic rubber semi-covered air valve (30) is united (using a process of vulcanization or use of an adhesive) with the inner tube (20) to make the improved inner tube which is incorporated inside the improved tire (10). Where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com