Semiconductor device having polycide wiring layer, and manufacturing method of the same

a technology of silicide layer and semiconductor device, which is applied in the direction of semiconductor device, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of increased rc delay, inability to control the thickness of the silicide layer with high precision, and inapplicable polycide wiring structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment (

Trench-Type DRAM)

[0037] A semiconductor device according to the first embodiment of the present invention and a method for manufacturing the semiconductor device will now be described, referring to FIGS. 1 through 11. In the description of the first embodiment, the semiconductor device is a trench-type DRAM to which a polycide wiring structure is applied.

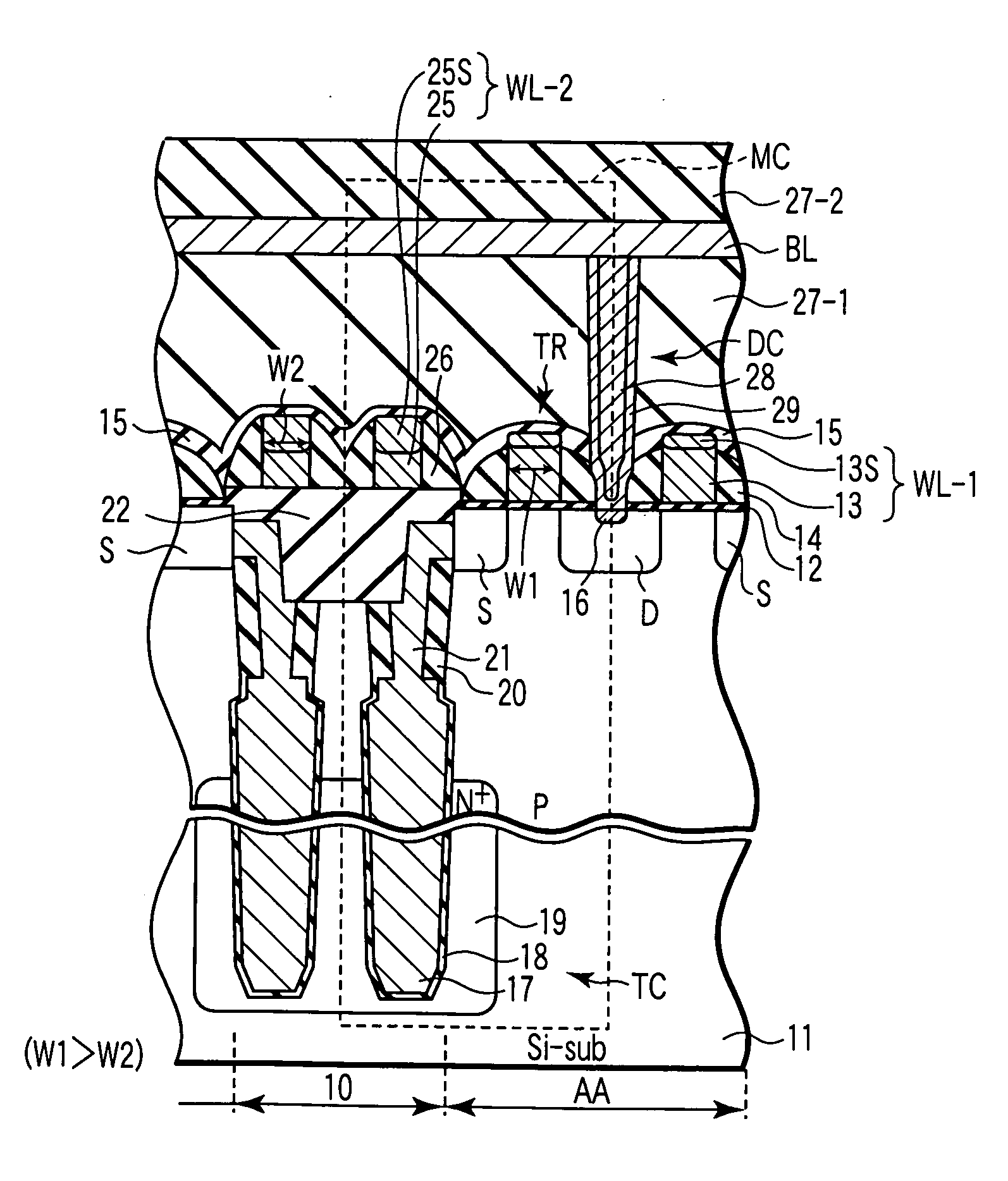

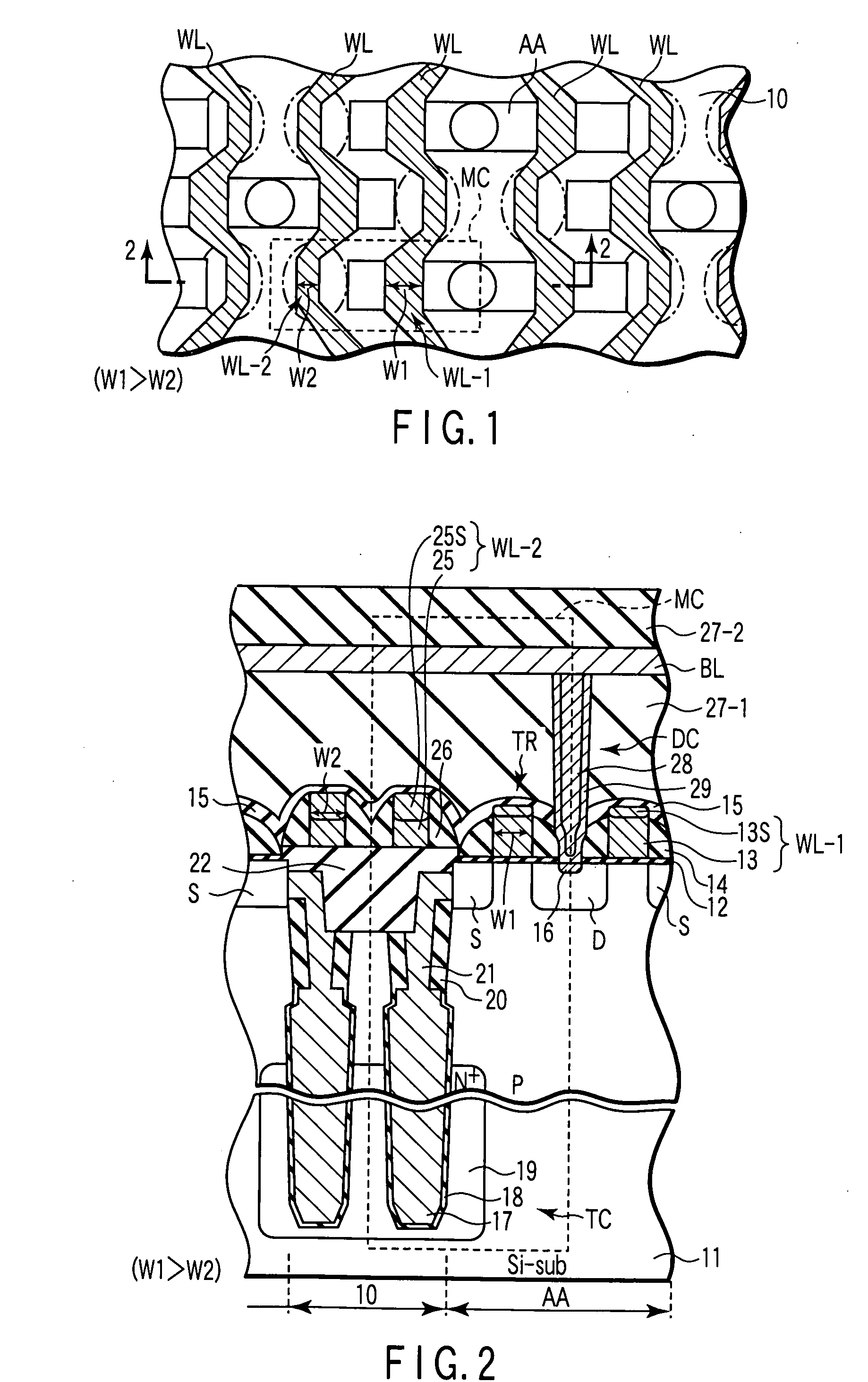

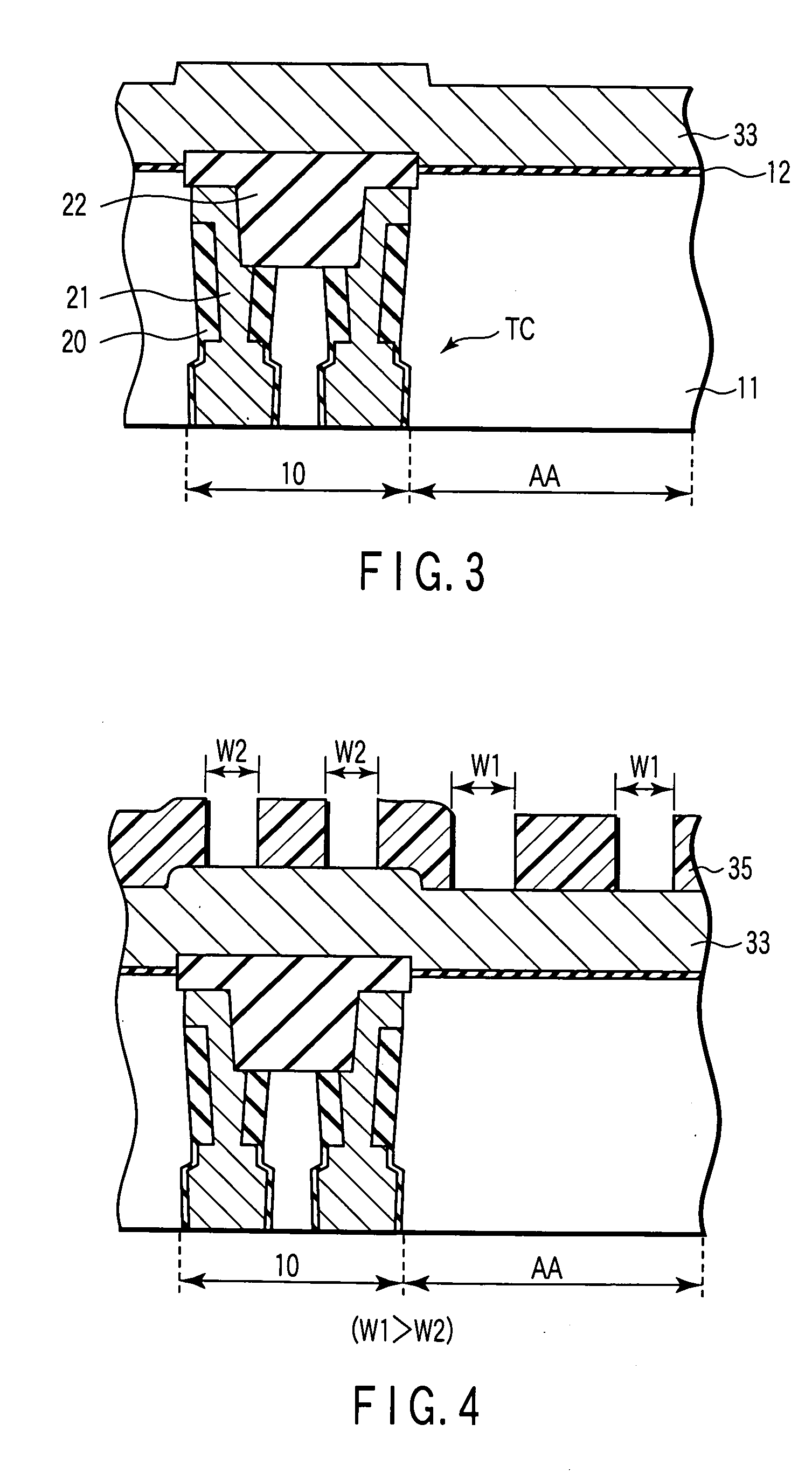

[0038]FIG. 1 is a plan view schematically illustrating a semiconductor device according to the first embodiment of the present invention. FIG. 2 is a sectional view taken along line 2-2 of FIG. 1.

[0039] Referring to FIGS. 1 and 2, an active area AA is formed on a P-type silicon substrate 11, and bit lines BL (not shown in FIG. 1) is provided in the active area AA. Word lines WL (conductive layers) are provided in such a manner that they extend in the direction crossing the bit lines BL. Trench-type DRAMs are provided at the intersections between the bit lines BL and the word lines WL. In FIGS. 1 and 2, the area indicated by the br...

second embodiment (

Trench-Type DRAM)

[0067] A semiconductor device according to the second embodiment of the present invention will now be described, referring to FIG. 9. In the descriptions below, structural elements similar to those of the first embodiment will not be mentioned for the sake of simplicity.

[0068]FIG. 9 is a sectional view taken in the same direction as FIG. 2.

[0069] As shown in FIG. 9, the spacer 26 and the shoulder portion 30 of silicide layer 25S are exposed more than the spacer 14 and the shoulder portion 31 of silicide layer 13S. In other words, spacer 26 is located higher than spacer 14.

[0070] The silicide layer 25S of the wiring layer WL-2 is thicker than the silicide layer 13S of the gate electrode WL-1. The silicide layer 25S of the semiconductor device of the second embodiment is thicker than the silicide layer 25S of the semiconductor device of the first embodiment.

[0071] As described above, in the semiconductor device of the second embodiment, the silicide layer 25S of t...

third embodiment (

Logic Circuit)

[0092] A semiconductor device according to the third embodiment of the present invention will now be described, referring to FIGS. 17 and 18. In the descriptions below, structural elements similar to those of the first and second embodiments will not be mentioned for the sake of simplicity. The third embodiment will be described, referring to a logic circuit having a polycide wiring structure.

[0093]FIG. 17 is a plan view schematically illustrating a semiconductor device according to the third embodiment of the present invention. FIG. 18 is a sectional view taken along line 18-18 of FIG. 17.

[0094] As shown in FIG. 18, transistors TR1 and TR2 are provided in an element region AA on the major surface of the semiconductor substrate 11. A wiring layer WL-2 is provided in an element isolation region 10, which is realized by shallow trench isolation (STI).

[0095] Transistor TR1 includes: a polysilicon layer 52 provided on a gate insulating film 51; a silicide layer 52S prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com