Candle system for enhancing burning and improving volatiles performance and a manufacturing method for the same

a technology of volatiles and candle shells, applied in the field of candle shell systems, can solve the problems of fragrance oil, furniture surface, possible fragrance oil, etc., and achieve the effect of better candle burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

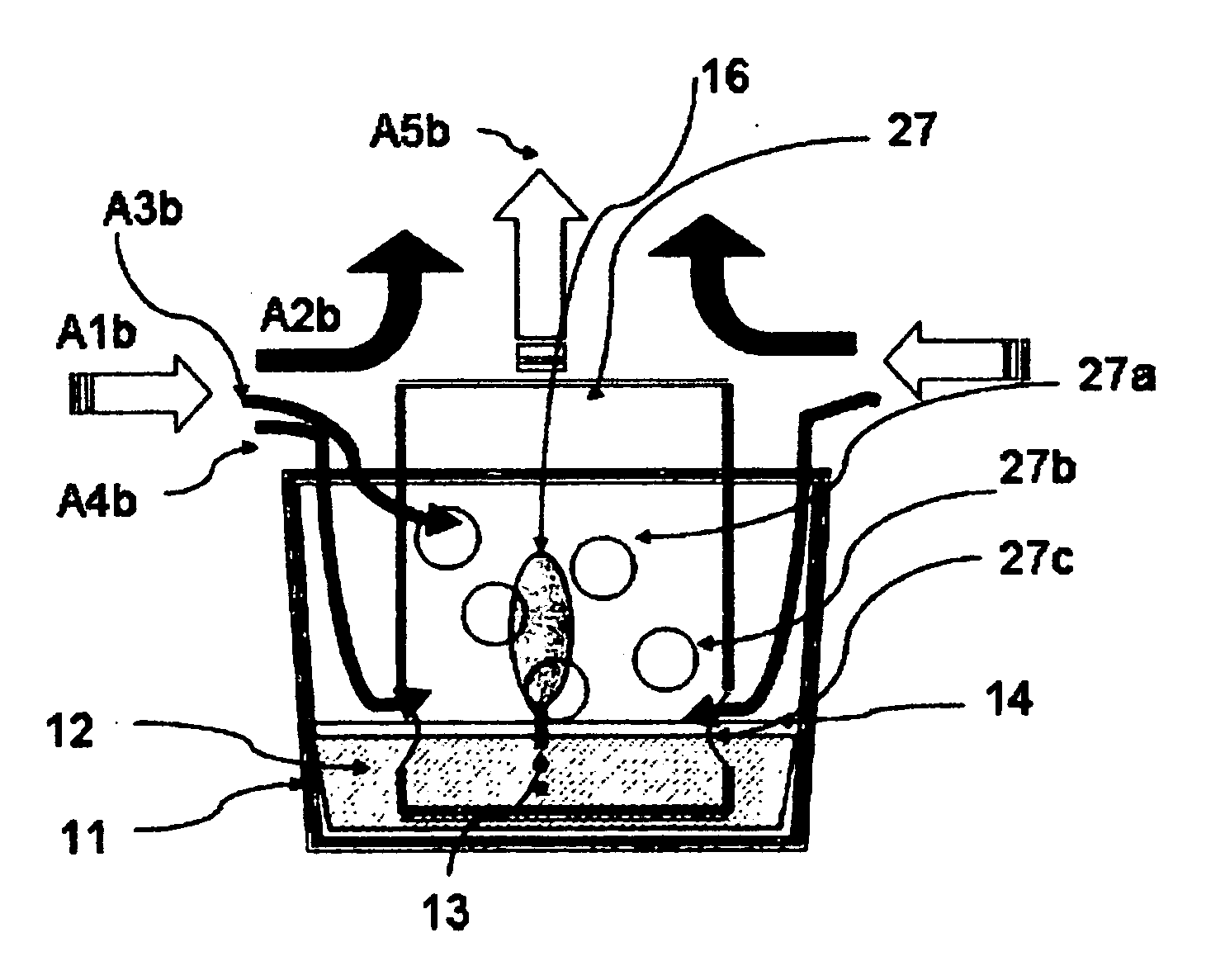

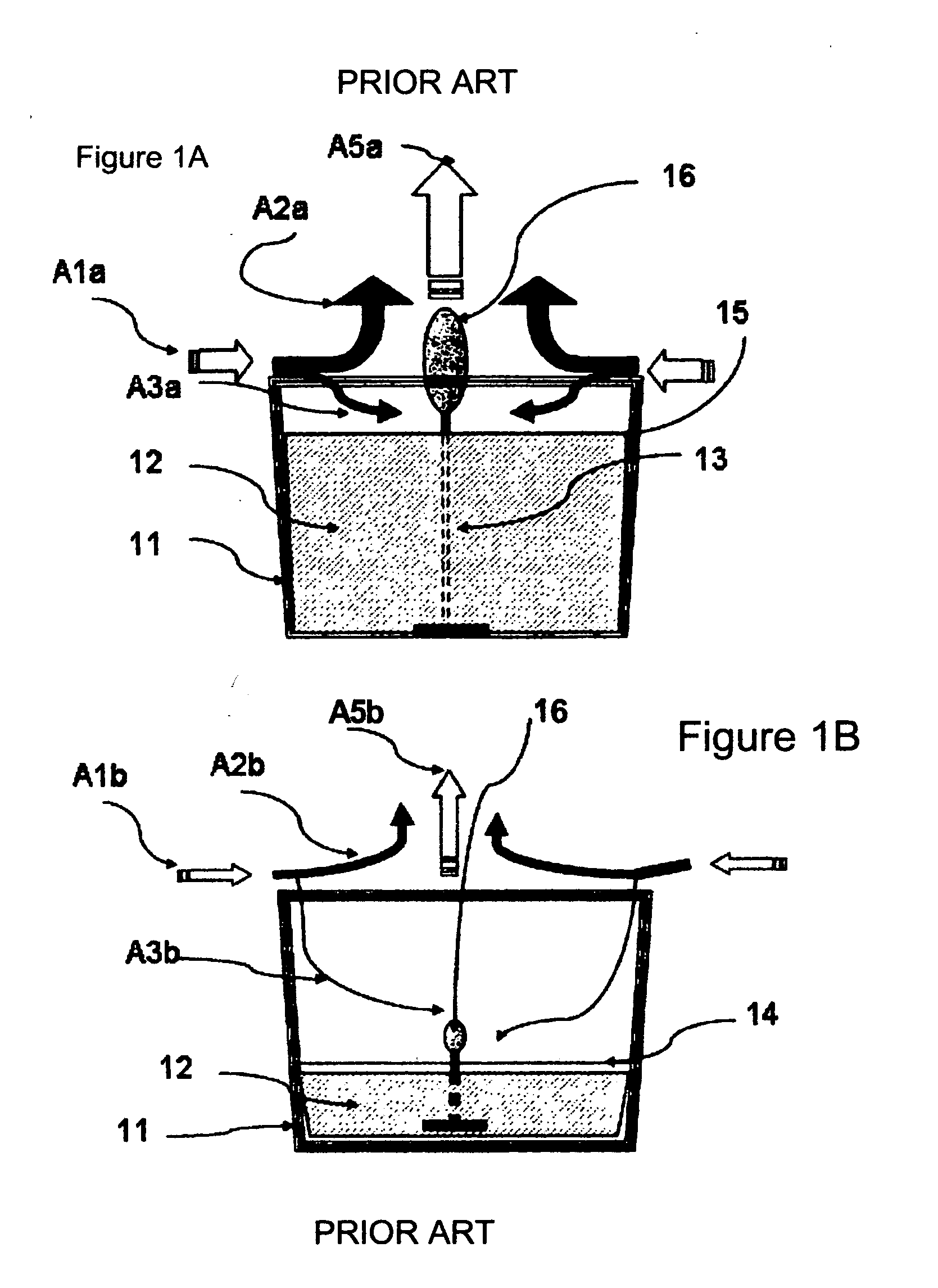

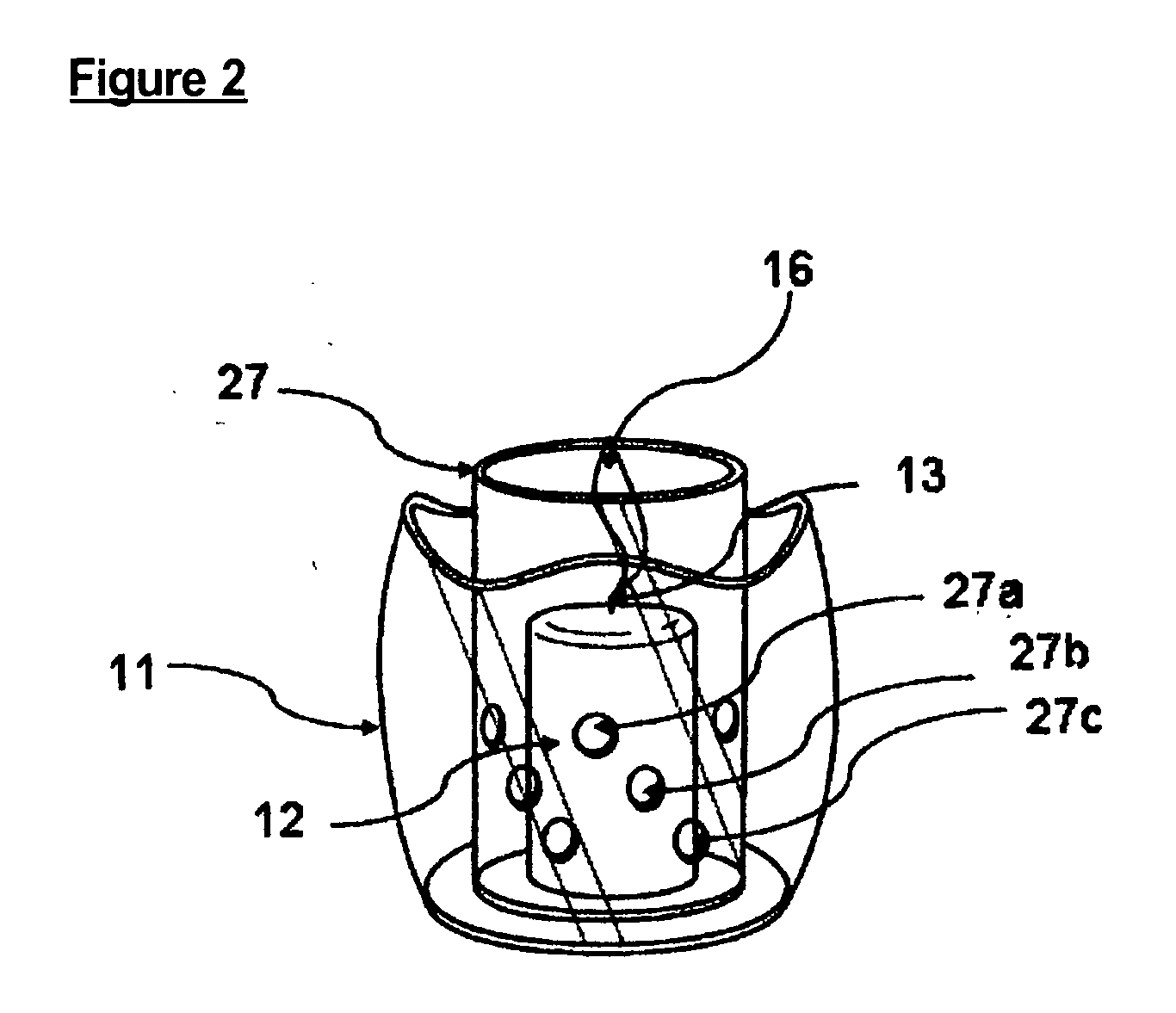

[0052] The present invention is manufactured by the following method, but is not limited to the precise steps noted below. Those skilled in the art will recognize that adaptations may be made to the present method without departing from the scope and spirit of the present invention. The twelve holes (27a, 27b, and 27c, etc.) are 8 mm in diameter, made using an electric drill on the sidewall of a plastic or glass inner-tube having the following dimensions, 57 mm diameter×70 mm height.

[0053] The four holes are placed at the upper portion of the inner-tube every 90 degree at ca. 20 mm lower from the top edge, another 4 holes are placed at the lower portion of the inner-tube every 90 degree and the holes at each level are 30 degree turned from the upper holes and lowered 32 mm lower from the top edge, at each level more 4 holes are drilled at the lowest portion of the inner-tube every 90 degree and 60 degree (30 degrees and 30 degrees) are turned from the upper holes at ca. 52 mm lower...

embodiment 2

[0054] The present invention is manufactured as described in Embodiment 1 and then the aforementioned inner-tube is positioned in the inside container, for example, 75 mm diameter×70 mm height glass jar. An appropriate length of wick is set in the inside of the inner-tube followed by filling with an appropriate volume of melting candle wax either with or without volatiles, and being solidified for use to approximately the level of the top-most holes 27a, allowing for slight air flow there through during initial use.

embodiment 3

[0055] The container of the present invention is compared with traditional candle container. Two commercial scented candles in the container (closed-candle) were purchased from a local market. Both candle waxes and wicks were removed from the containers and melted. The inner tube is set to the bottom of one of the containers and the melting wax poured into both containers with the same formula of commercial candle. After two hours, both candles' performance were compared.

Test Candle (with aControl CandleTimeinner-tube having holes)(no inner tube)0Very good burning withVery good burning withbrighter flamebright flame2 hoursVery good burning andPoor burning with poorstrong updraft with veryfragrance performancegood fragrance performance

[0056] Referring now to FIG. 5, another adaptive embodiment of the present invention is provided. As noted glass tube 50 (operable as an inner tube 27) rests on a seat 51 formed in a separable base or container member 52, for surrounding a burning wic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter×70 | aaaaa | aaaaa |

| diameter×70 | aaaaa | aaaaa |

| diameter×50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com