Capillary tube/plate refrigerant/air heat exchanger for use in conjunction with a method and apparatus for inhibiting ice accumulation in HVAC systems

a technology of ice accumulation and refrigerant, which is applied in the direction of defrosting, domestic cooling apparatus, etc., can solve the problems of system inability to acquire sufficient heat from the air to operate at design levels, shorten compressor life, and excessive wear, so as to reduce system operational design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

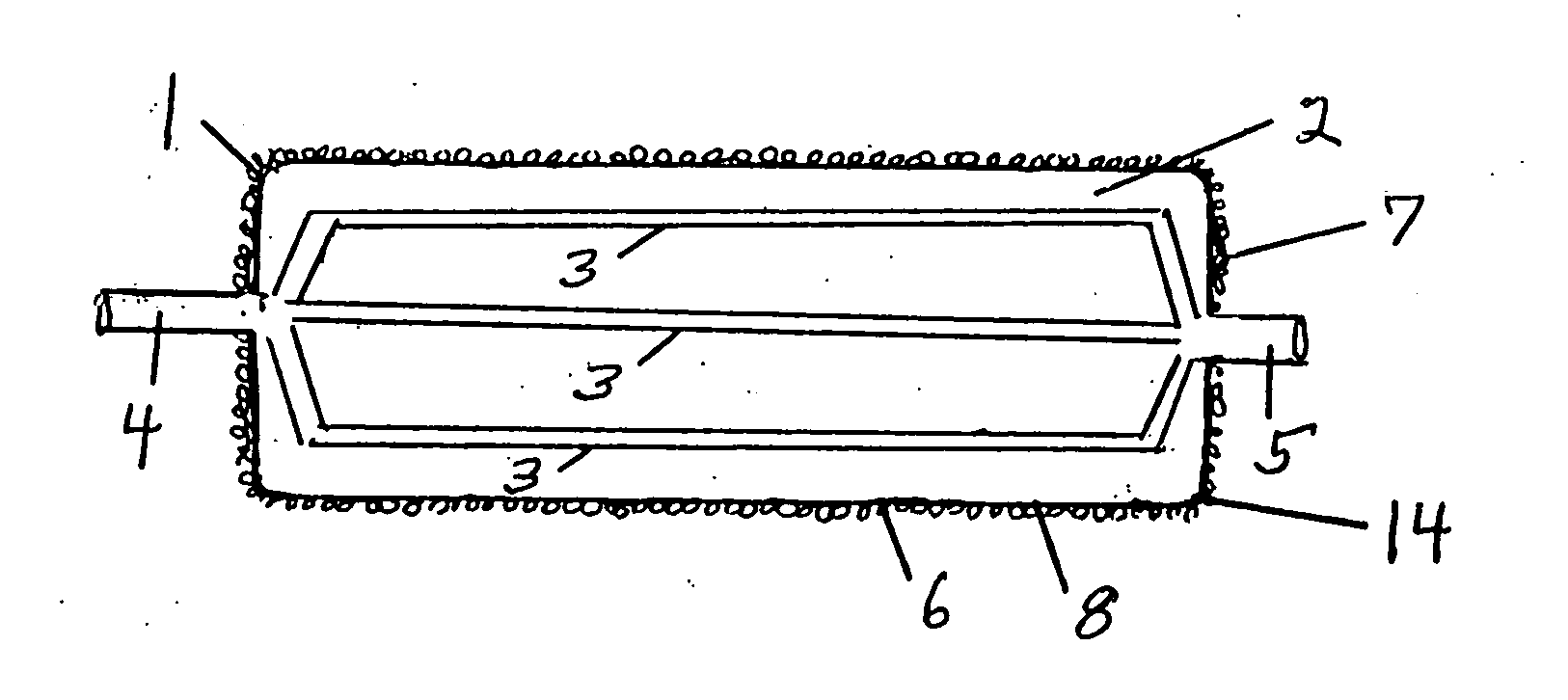

[0026] A method and apparatus for inhibiting condensation ice accumulation on heat transfer systems, including refrigerant-based heating and cooling systems, and on an evaporative cooling system, according to the invention, utilizes a non-stick coating applied to capillary tube / plate means / design heat exchange components where ice accumulation is not desirable because such ice decreases overall system operational efficiencies.

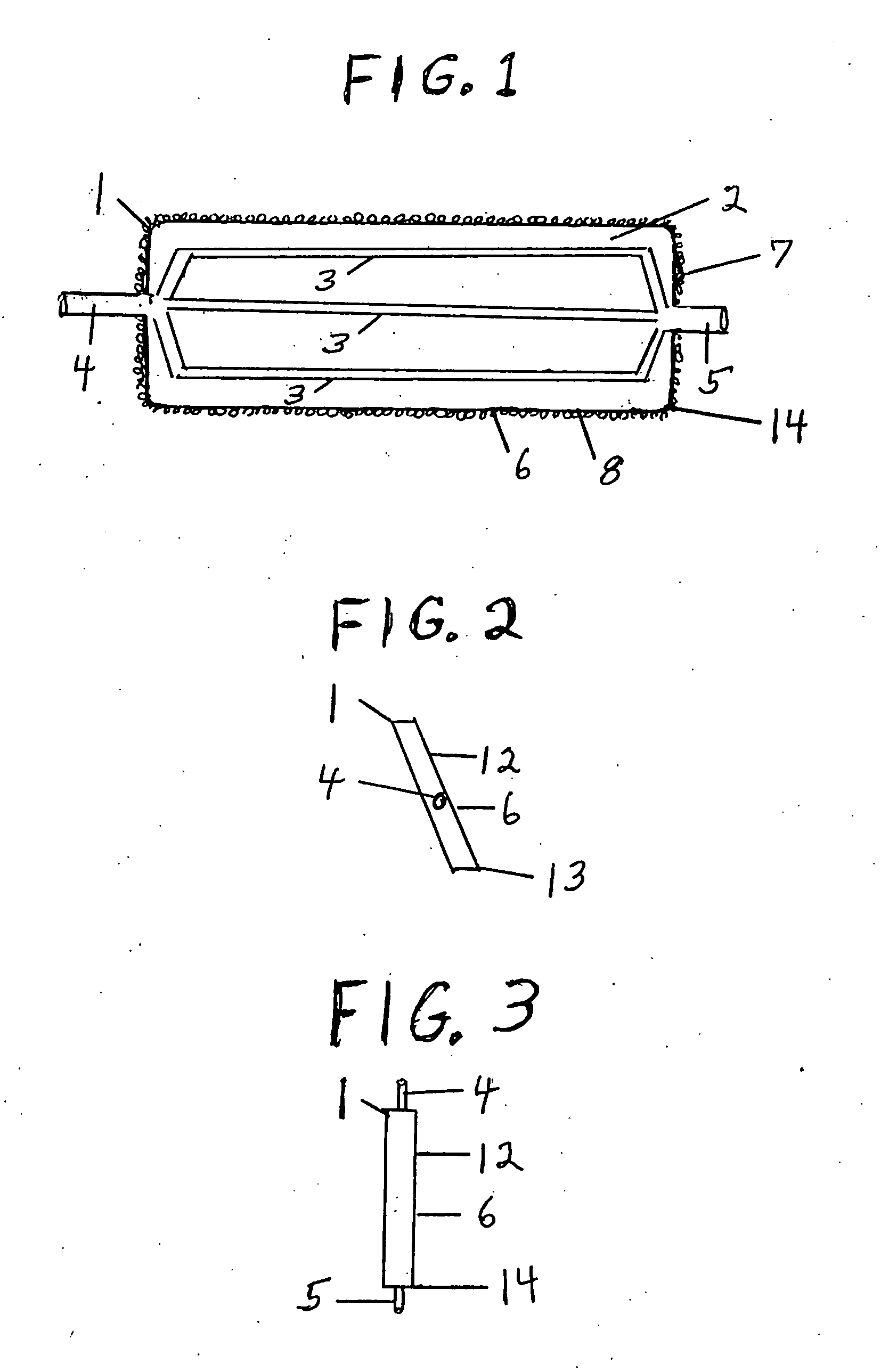

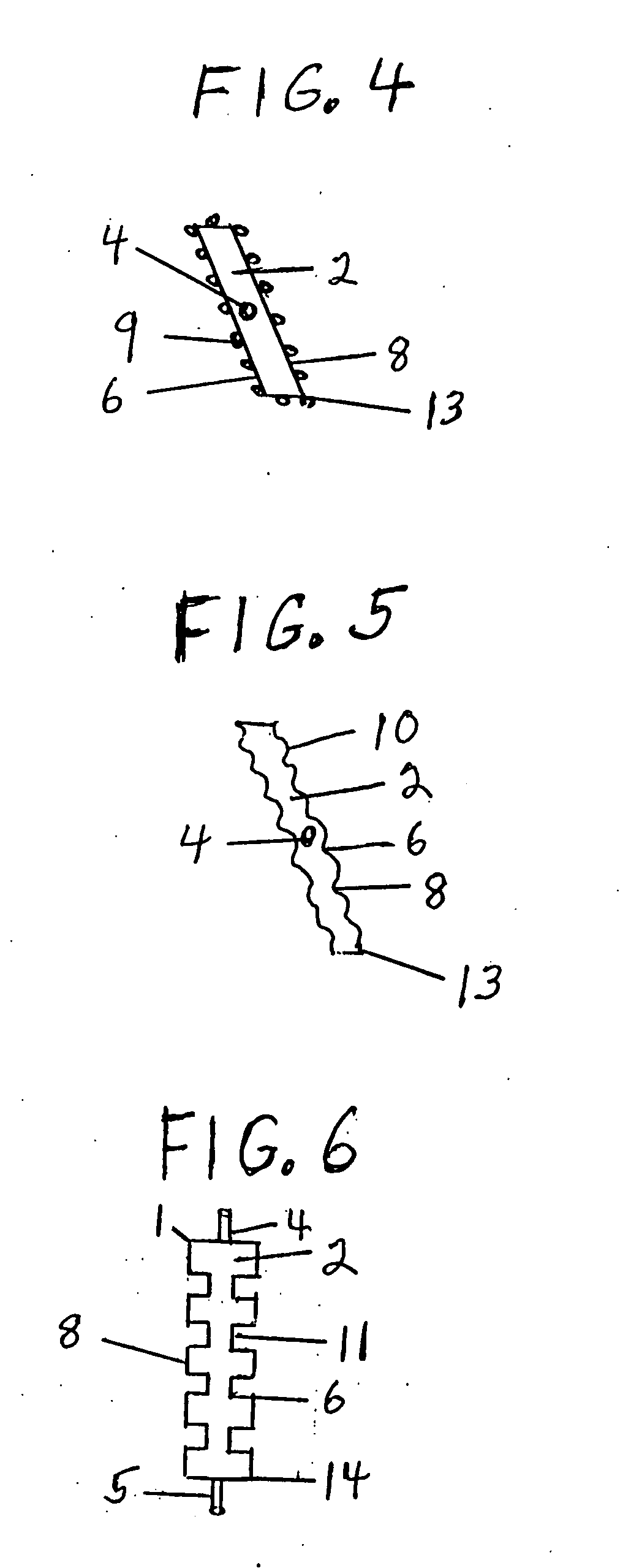

[0027] The following detailed description is of the best presently contemplated mode of carrying out the invention. The description is not intended in a limiting sense, and is made solely for the purpose of illustrating the general principles of the invention. The various features and advantages of the present invention may be more readily understood with reference to the following detailed description taken in conjunction with the accompanying drawings.

[0028] Referring now to the drawings in detail, where like numerals refer to like parts or elements, there ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heat conductive | aaaaa | aaaaa |

| gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com