Micro electromechanical systems thermal switch

a technology of electromechanical systems and thermal switches, applied in the direction of contacts, semiconductor devices, relays, etc., can solve the problems of thermal switches that cannot be reduced below, switches to premature failure, and limited applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

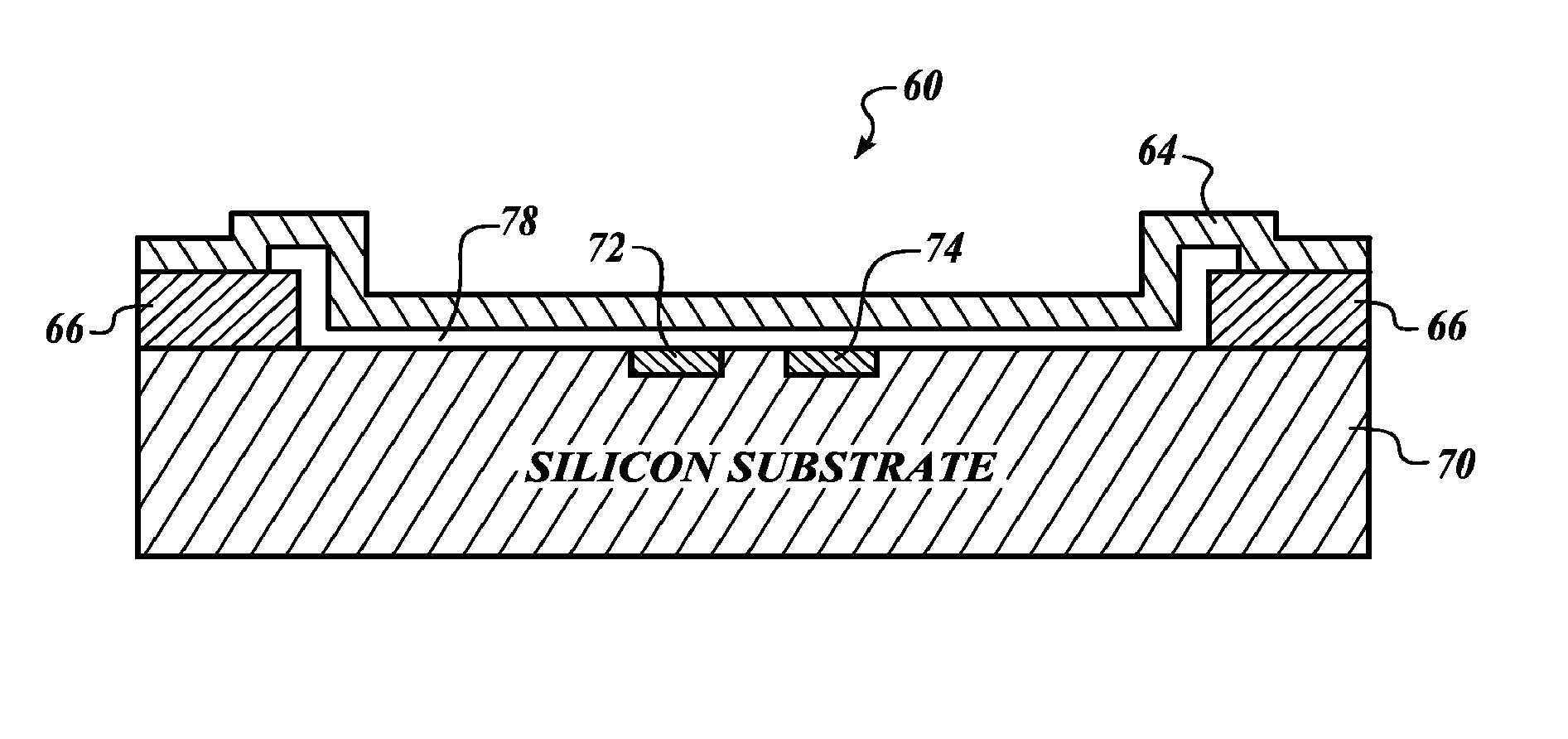

[0015] The present invention is a Micro Electro-Mechanical Systems (MEMS) thermal switch with electrostatic control. FIG. 1A illustrates a perspective view of a single beam MEMS thermal switch 20. The thermal switch 20 includes a beam 24 that is arched over a source 26 and a drain 28 that are created within a silicon substrate 30.

[0016]FIG. 1B illustrates a cross-sectional view of the thermal switch 20 along a longitudinal axis of the beam 24. The source 26 and drain 28 are embedded within silicon substrate 30. The silicon substrate 30 is suitably a silicon wafer. Layered on top of the source 26 and the drain 28 is a gate oxide layer 32. The beam 24 is attached at its ends to insulator mounts 34. The insulator mounts 34 are attached to the gate oxide layer 32 on opposite sides of the source 26 and the drain 28 in order to allow the beam 24 to arch over the source 26 and the drain 28. In one embodiment, the beam 24 includes a monolithic beam. A monolithic beam is a single metal beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com