Generator set exhaust processing system and method

a technology of exhaust processing and generator sets, applied in the direction of vessel auxillary drives, marine propulsion, vessel construction, etc., can solve the problems of variable components, inapplicability of devices to smaller watercraft, and watercraft employing exhaust processing devices in conjunction, so as to reduce undesirable components of exhaus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

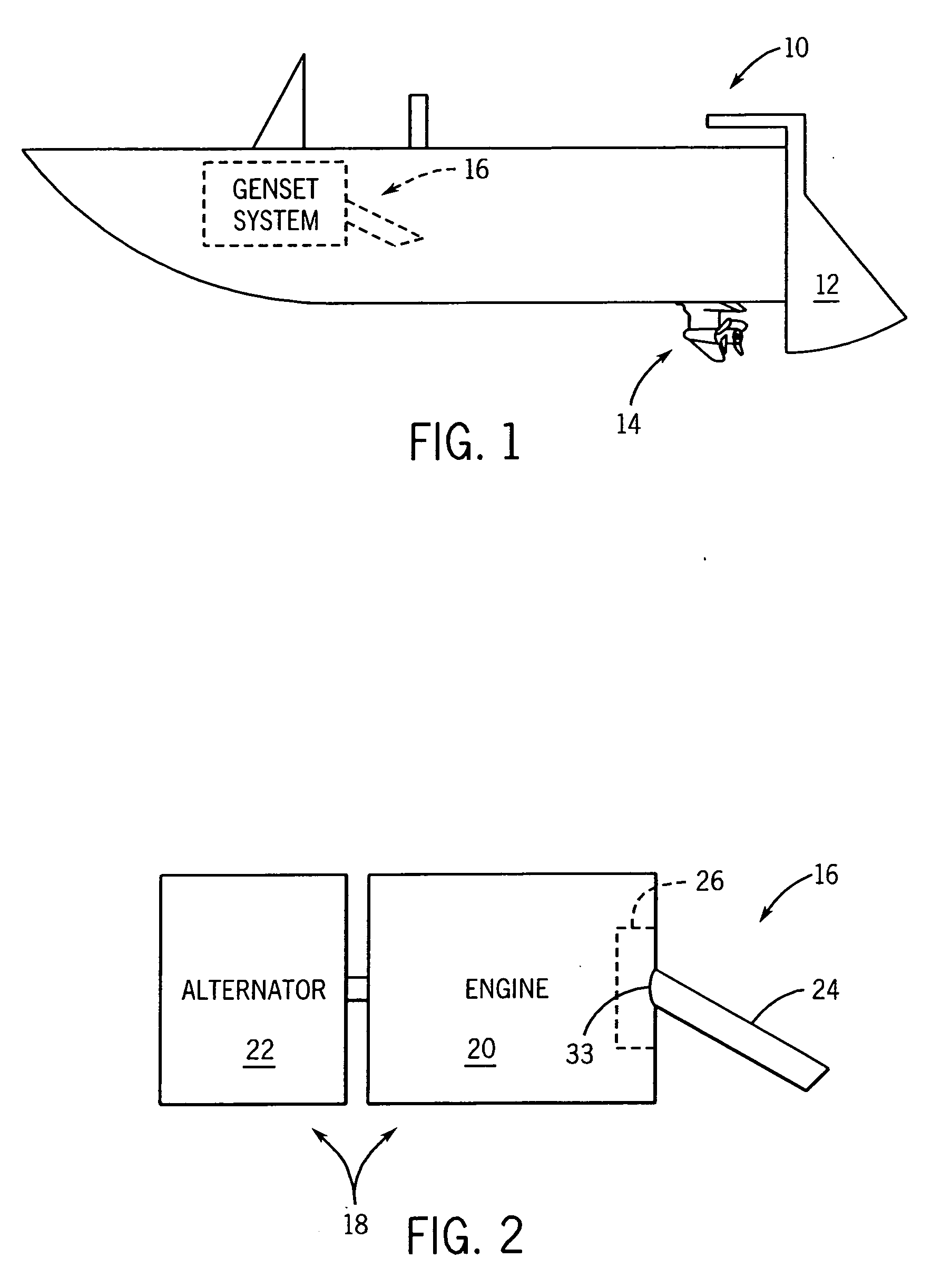

[0018] Referring to FIG. 1, a small watercraft 10 is represented as a speedboat. The watercraft includes, among other components, a rudder 12 and a propeller 14 that is driven to propel the boat through the water. Additionally, as will be described, the watercraft 10 includes a generator set (or “genset”) system 16. The watercraft 10 could be, for example, a pleasure craft having a length in the range of 26 feet to 38 feet. Although shown to be a speedboat, the watercraft 10 is intended to be representative of a wide variety of different watercraft including, for example, sport boats, cruisers, sailboats, yachts, fishing boats, jet boats, and the like that employ gensets. In this regard, the present invention is intended to be applicable to a wide variety of smaller watercraft or other devices that employ gensets and that are able to draw upon a source of water.

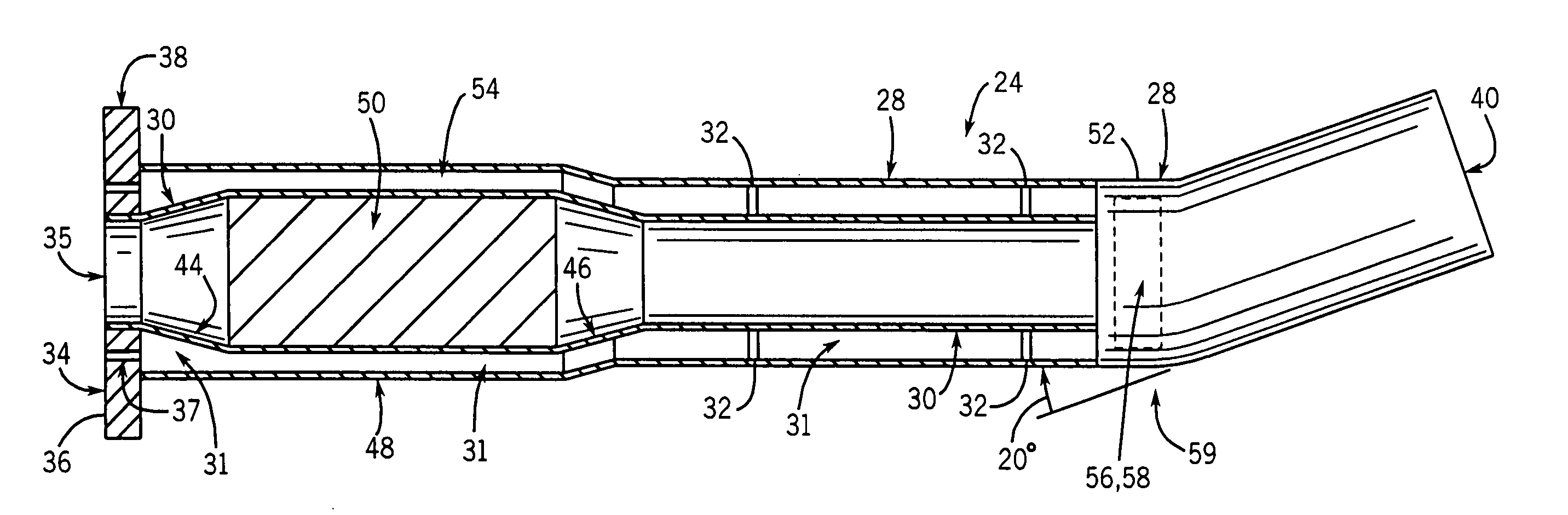

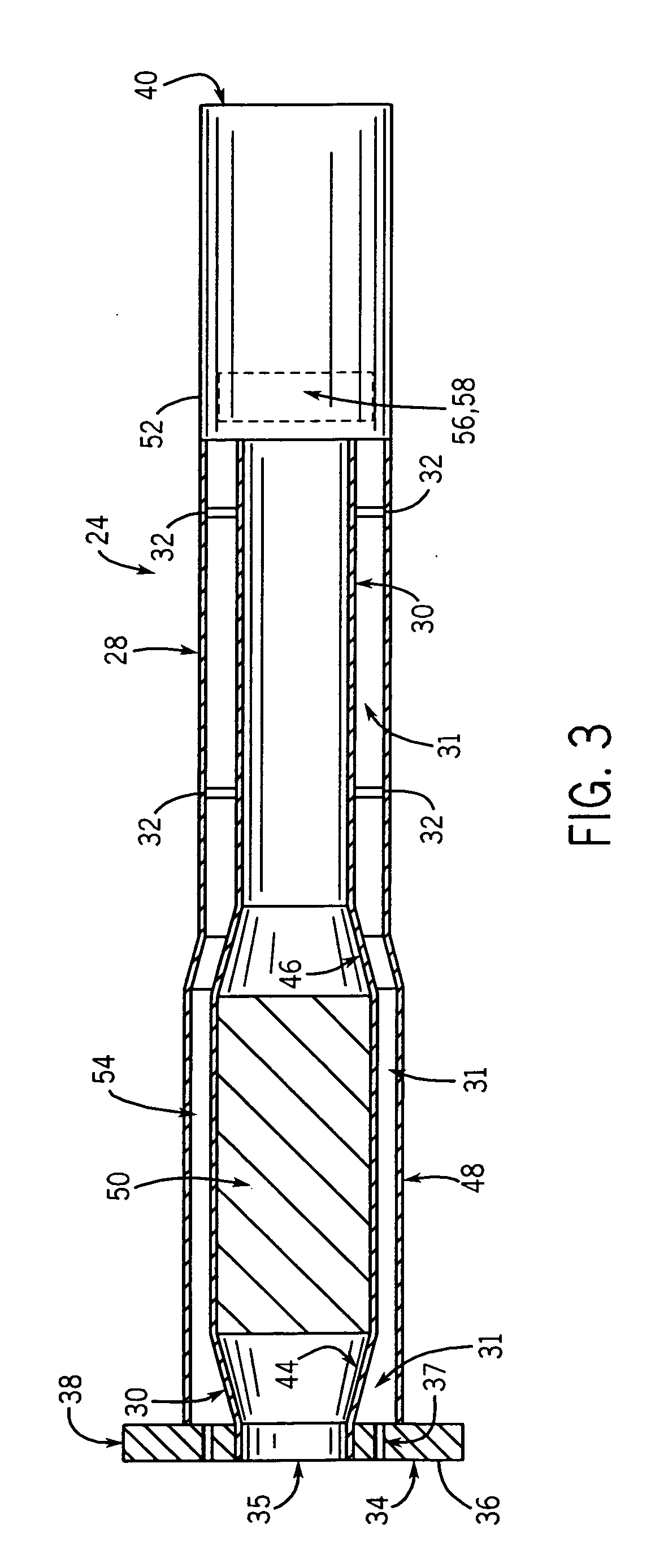

[0019] Referring additionally to FIG. 2, the genset system 16 is shown in detail. The generator set assembly 16 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com