Aluminium alloy with increased resistance and low quench sensitivity

a technology of quench sensitivity and alloy, applied in the field of aluminum alloy, can solve the problems of increasing the cooling rate, high quench sensitivity of alloy employed today for mould manufacturing, and achieving the effect of adequate high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

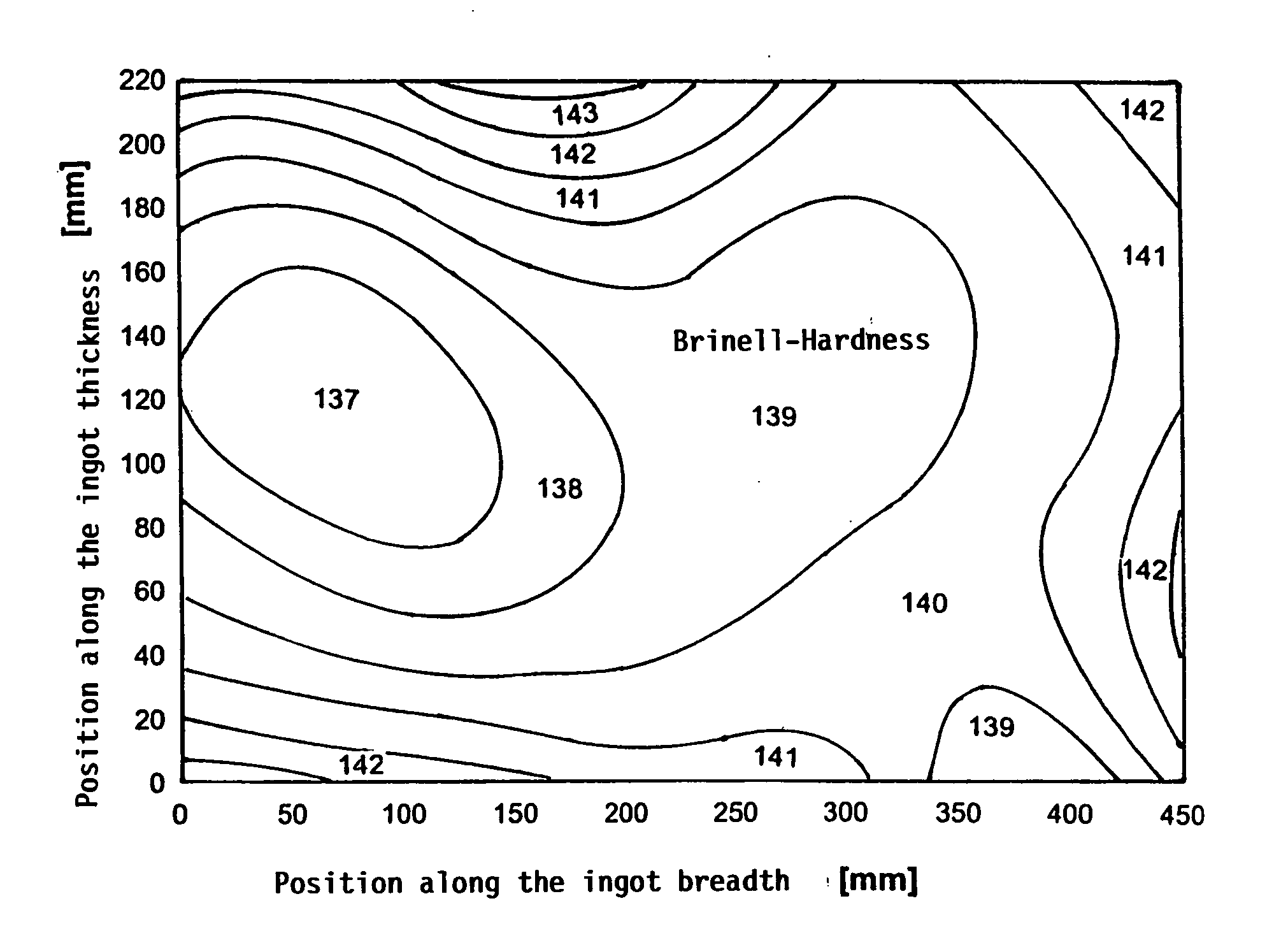

[0049] An alloy with the composition (in wt. %) : 0.040 Si, 0.08 Fe, 0.14 Cu, 0.0046 Mn, 2.69 Mg, 0.0028 Cr, 4.69 Zn, 0.017 Ti, 0.16 Zr, rest Al was cast on an industrial scale as a continuously cast ingot of cross-section 440 mm×900 mm. The ingots were heated within 30 h to a temperature of 480° C., whereby the heating rate in the range 170-410° C. was less than 20° C. / h. The homogenisation of the ingot to equalise the segregation arising during solidification was performed by holding the ingot for 12 h at 480° C.

[0050] The homogenised ingots were cooled from the homogenisation temperature in a first stage in still air to an intermediate temperature of 400° C. and subsequently in a second stage with forced air cooling from 400° C. to 100° C. The further cooling to room temperature took place again in still air.

[0051] After 14 days at room temperature, the ingots were artificially age-hardened for 8 h at 95° C. followed by 18 h at 155° C. to the over-aged condition T76.

[0052] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com