Composite elastomeric yarns

a technology of elastomeric yarns and composite yarns, which is applied in the field of composite elastomeric yarns, can solve the problems of unfavorable finished products, difficult handling in typical textile yarn and fabric manufacturing processes, and unfavorable human body contact, and achieves superior aesthetics and enhances the ability of the manufacturer to vary the fiber density and/or bulk of the resulting composite yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The Yarns

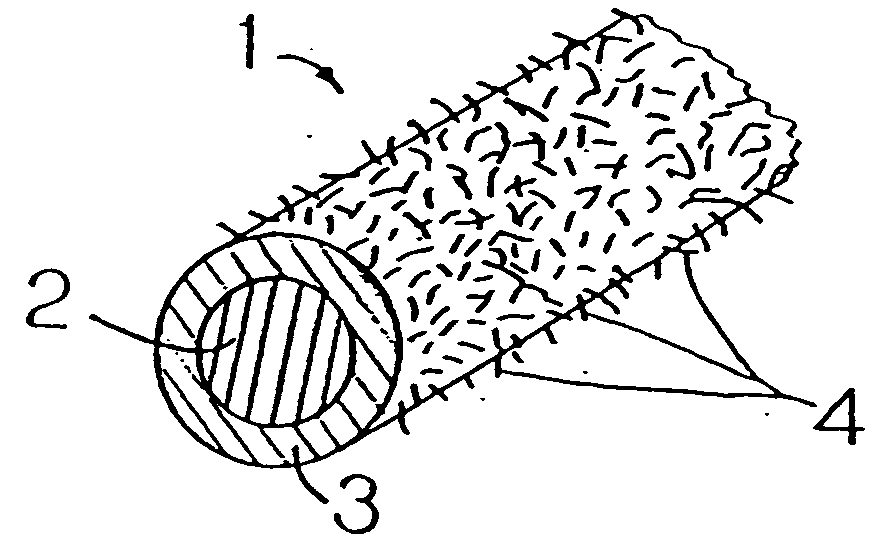

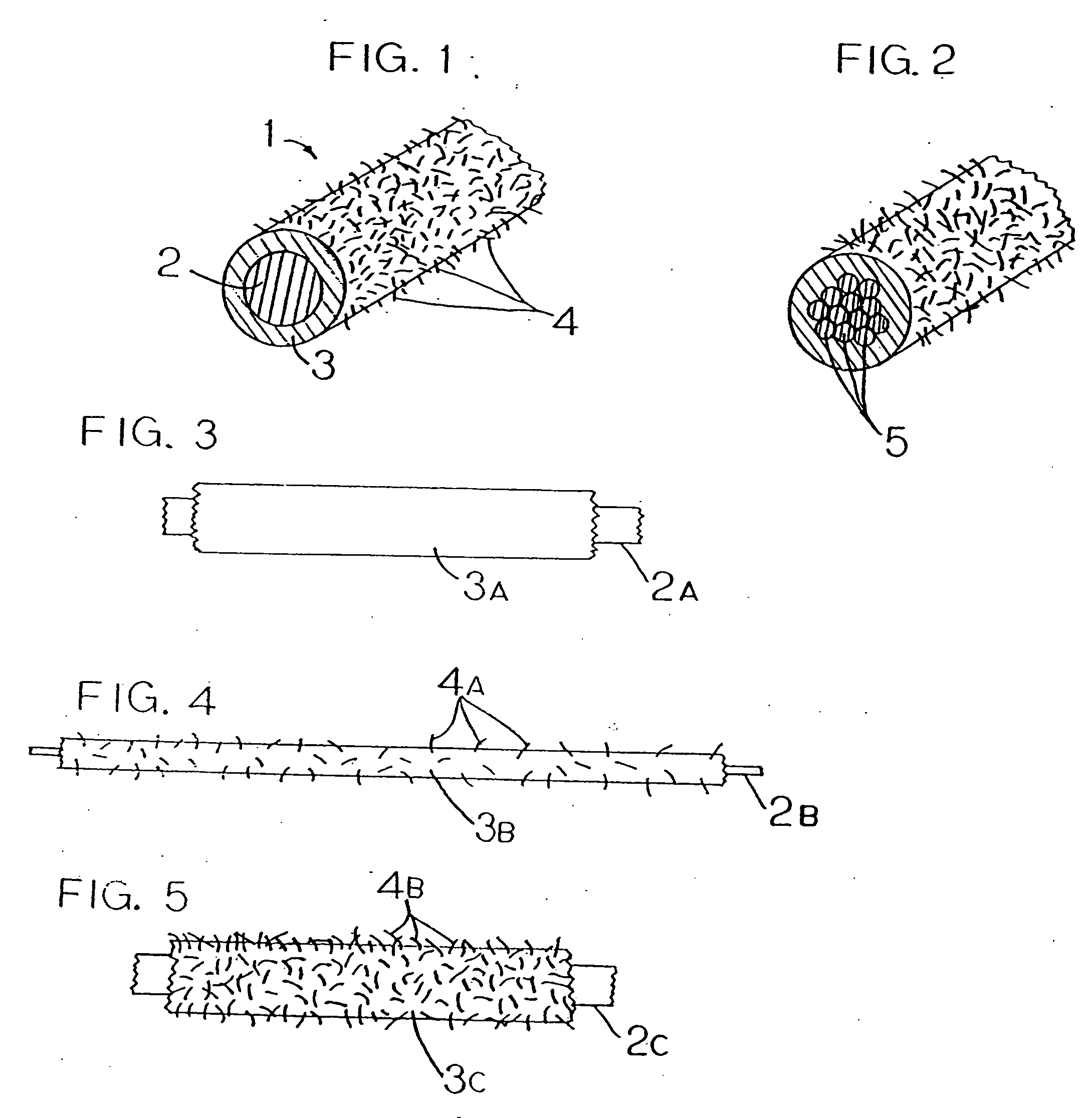

[0019] As disclosed herein, the preferred composite yarns of the present invention have improved properties both in high elongation / low modulus embodiments as well as low elongation / high modulus embodiments. More specifically, the composite yarns of the present invention provide an aesthetically pleasing outer surface in both elongated and relaxed form, improved adherence of surface fibers to the elastomeric core, and improved abrasion resistance. Further, the preferred composite yarns of the present invention are able to lock in and hide electro-conductive yarns in the interior as well as cover flammable elastomers with non-flammable or fire resistant fibers to produce elastic yarns which will not burn or propagate flame spread.

[0020] From an aesthetic perspective, composite yarns of the present invention can be produced with varying degrees of bulk and varying moduli depending on the desired application, and can be brushed in yarn or fabric form resulting in mini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point temperature | aaaaa | aaaaa |

| melting point temperature | aaaaa | aaaaa |

| melting point temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com