Pulsed mass flow measurement system and method

a mass flow and measurement system technology, applied in the direction of liquid/fluent solid measurement, instruments, coatings, etc., can solve the problem of slow flow sensor and achieve the effect of high repeatability and precise quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

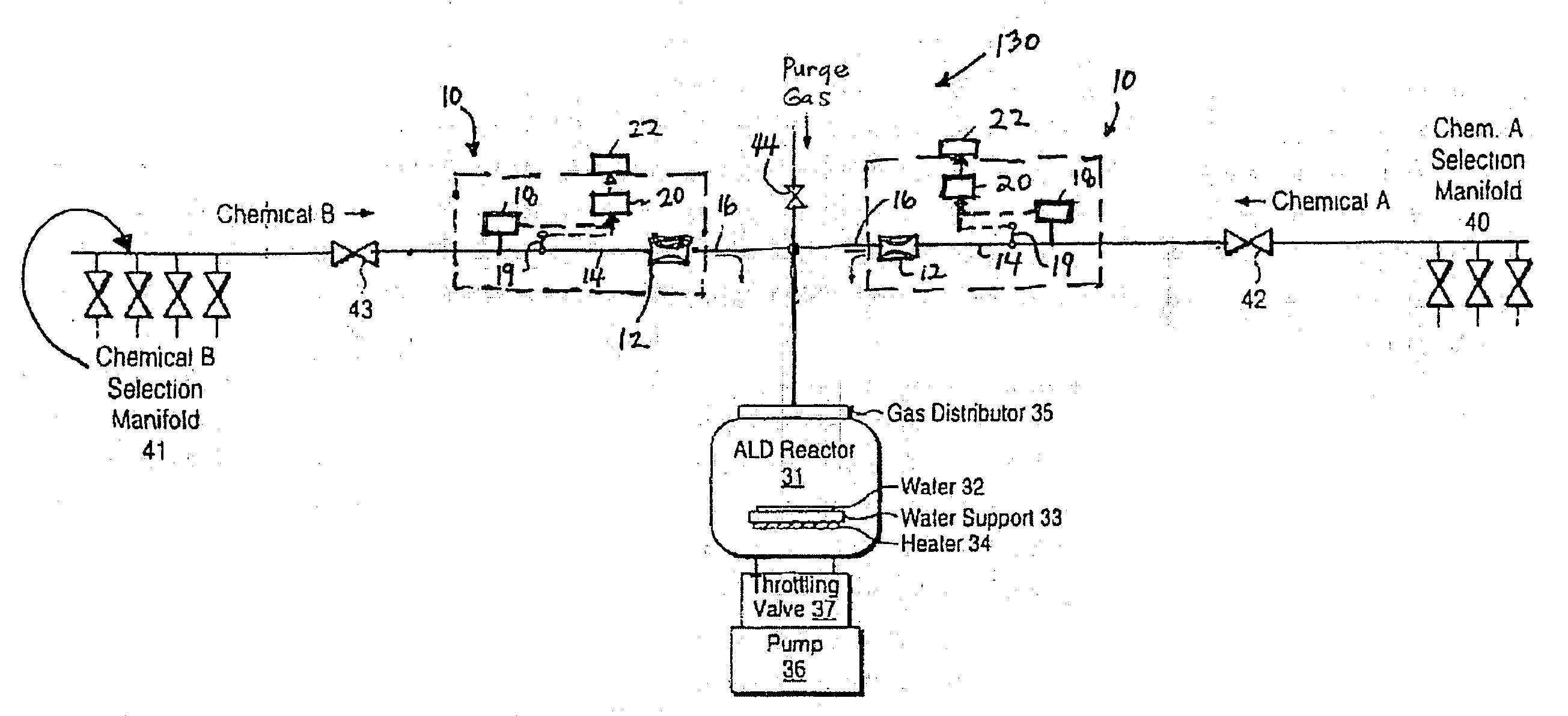

[0020] Referring to FIG. 1, the present disclosure provides an exemplary embodiment of a mass flow measurement system 10 constructed in accordance with the present invention. The system 10 is particularly intended for delivering contaminant-free, precisely metered quantities of process gases to semiconductor process chambers. The mass flow measurement system 10 actually measures the amount of material (mass) flowing into the process chamber. In addition, the system 10 provides highly repeatable and precise quantities of gaseous mass for use in semiconductor manufacturing processes, such as atomic layer deposition (ALD) processes. Prior to describing the system 10 of the present disclosure, however, an example of a semiconductor manufacturing apparatus is first described to provide background information.

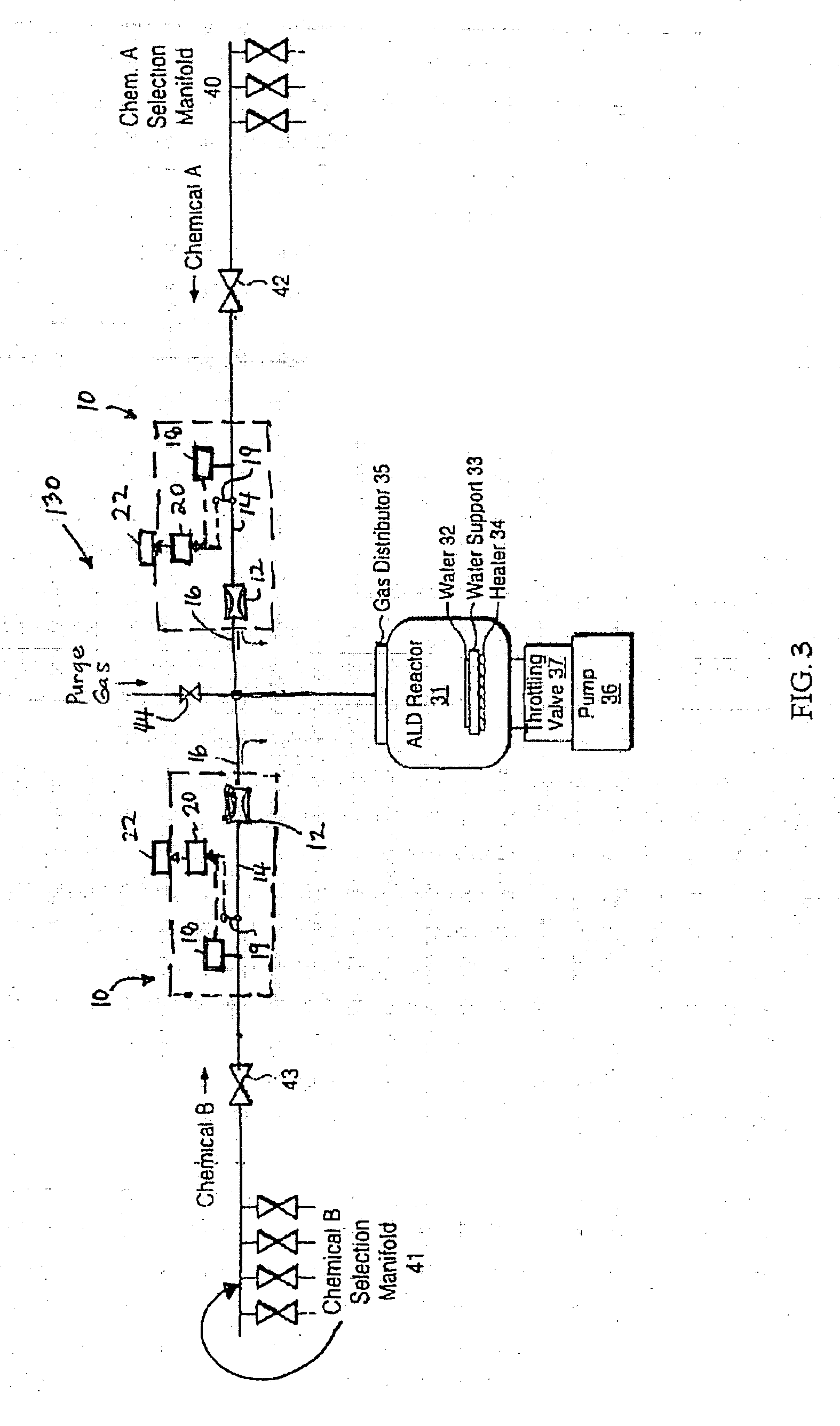

[0021]FIG. 7 is a schematic illustration of an exemplary embodiment of an atomic layer deposition system 30 constructed in accordance with the prior art. The system 30 includes a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com