Feed roll construction

a technology of feed rolls and construction, applied in the direction of conveyor parts, rollers, mechanical conveyors, etc., can solve the problems of large product loss, substantial number of kernels rendered unusable, and rupturing of some kernels, and achieve the effect of adequate frictional engagement and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

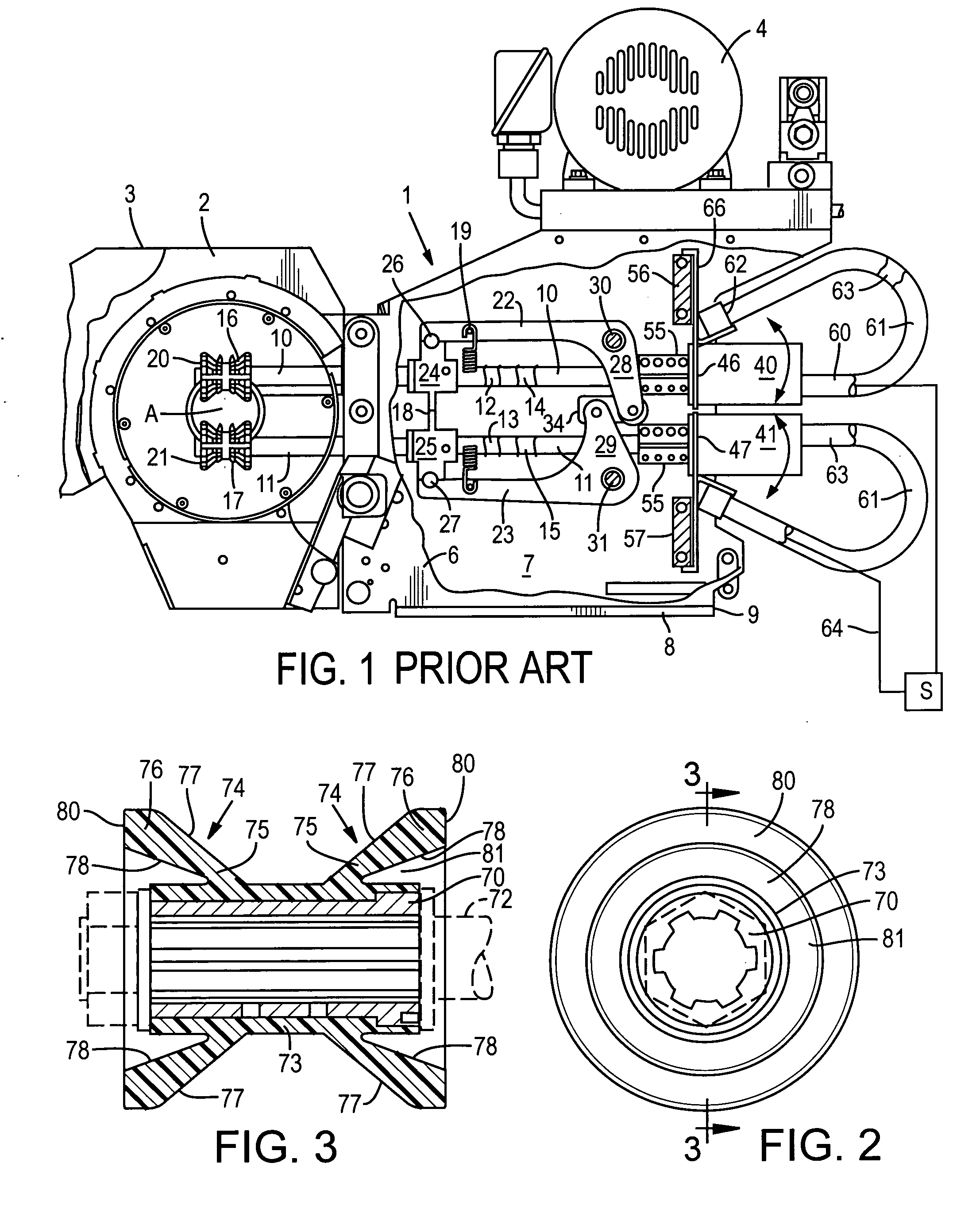

[0012] With continuing attention to the drawings wherein applied reference numerals indicate parts similarly hereinafter identified, the reference numeral 1, in U.S. Pat. No. 5,830,060, indicates a corn cutting machine used in food processing plants with a first pair of rolls or rollers 16-17 and a second pair at 20-21 all lug equipped. Typically, feed rolls are utilized in multiple pairs such as in the prior art machine shown and disclosed in FIG. 1 in U.S. Pat. No. 5,830,060 incorporated herein by reference. The corn processing machine shown therein has vertically displaceable feed rolls for processing articles of non-constant cross section.

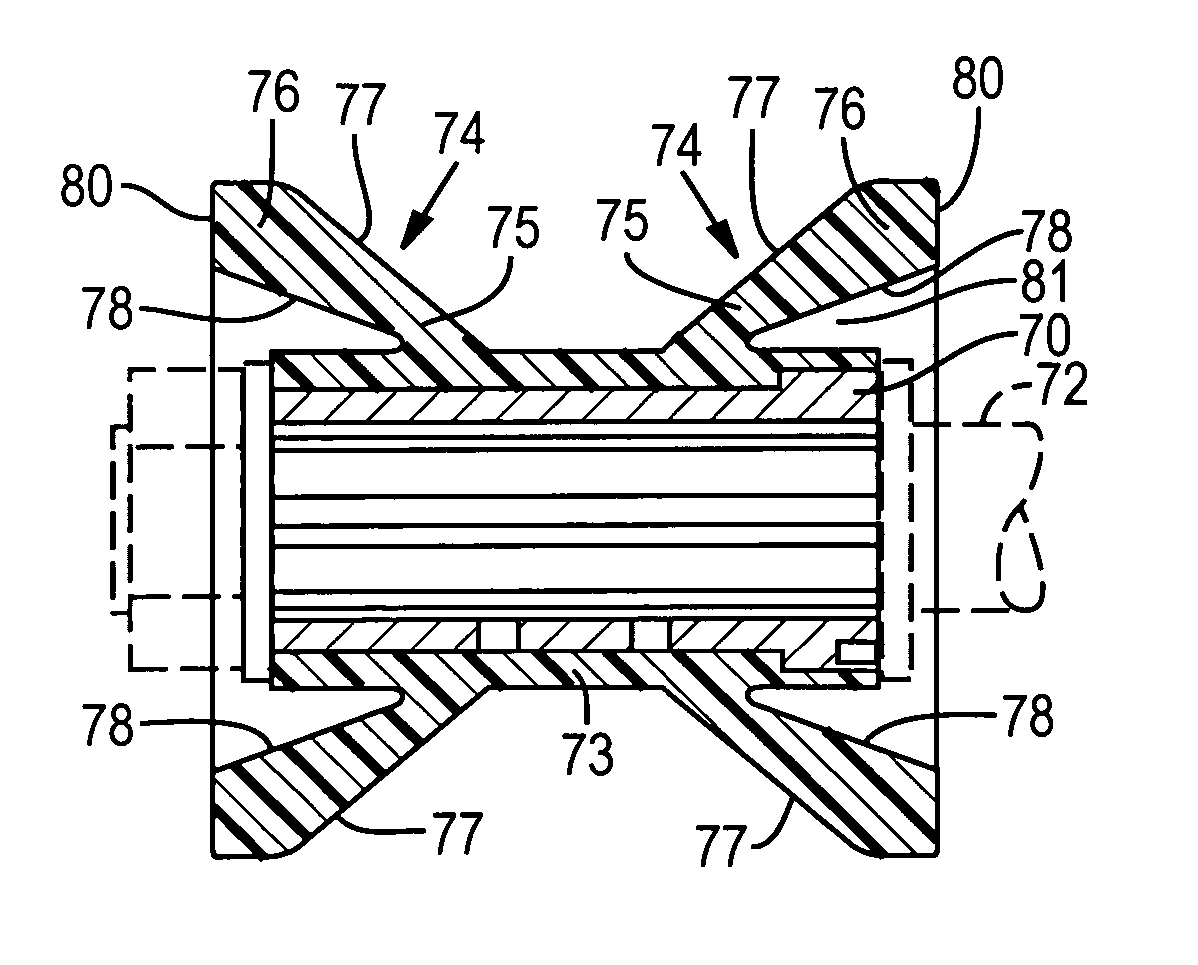

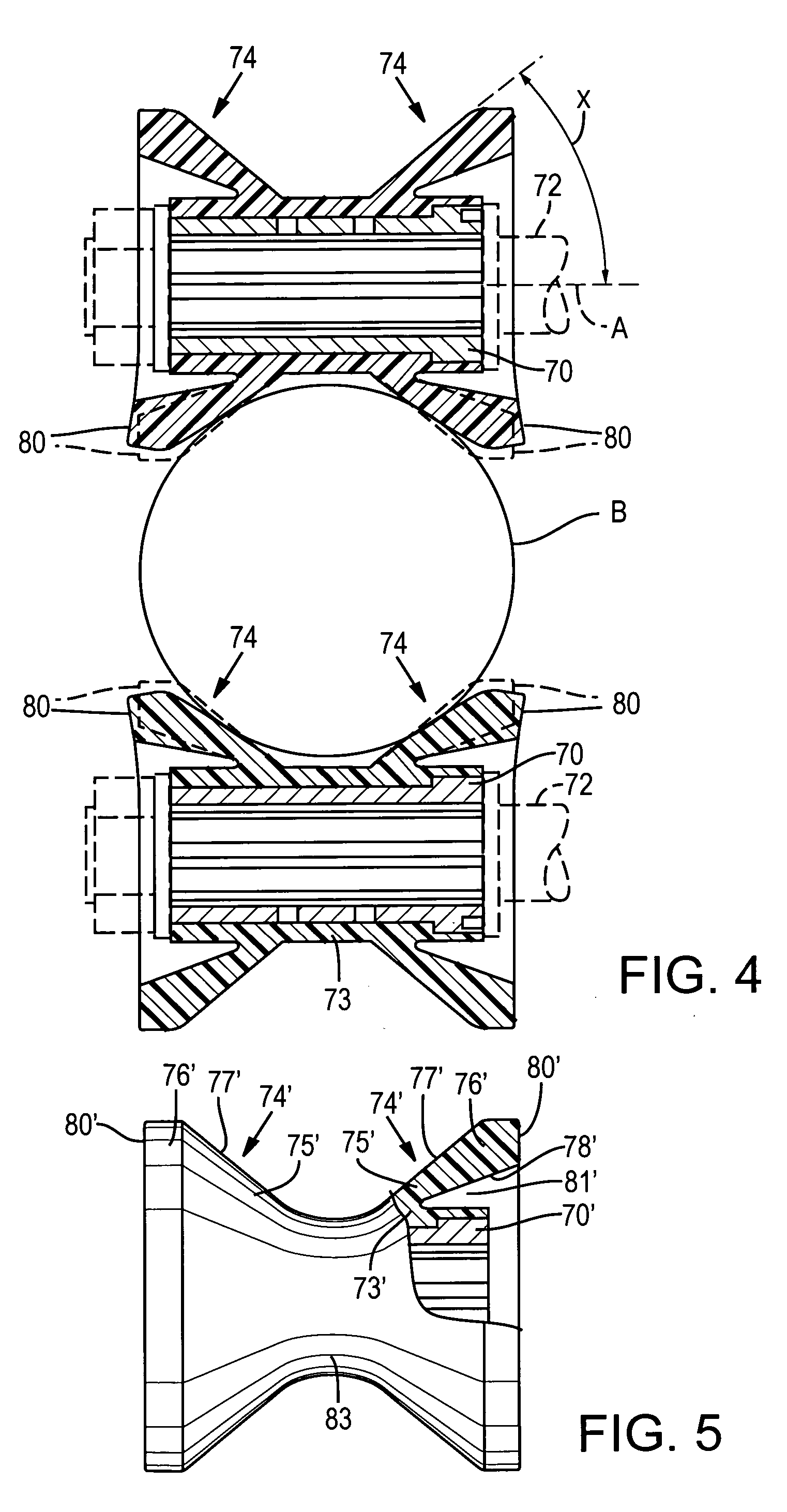

[0013] With attention now to the present roll, a hub is 70 is internally grooved or otherwise provided for driven engagement with a shaft 72. A sleeve at 73, of resilient material, is formed about the hub. End members at 74 of a roll are of generally of conical shape each having inner portions 75 merging with outer portions 76 and jointly prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com