Back-contacted solar cells with integral conductive vias and method of making

a solar cell and integral technology, applied in the field of back contact solar cells, can solve the problem of photocurrent loss in heavily doped emitters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

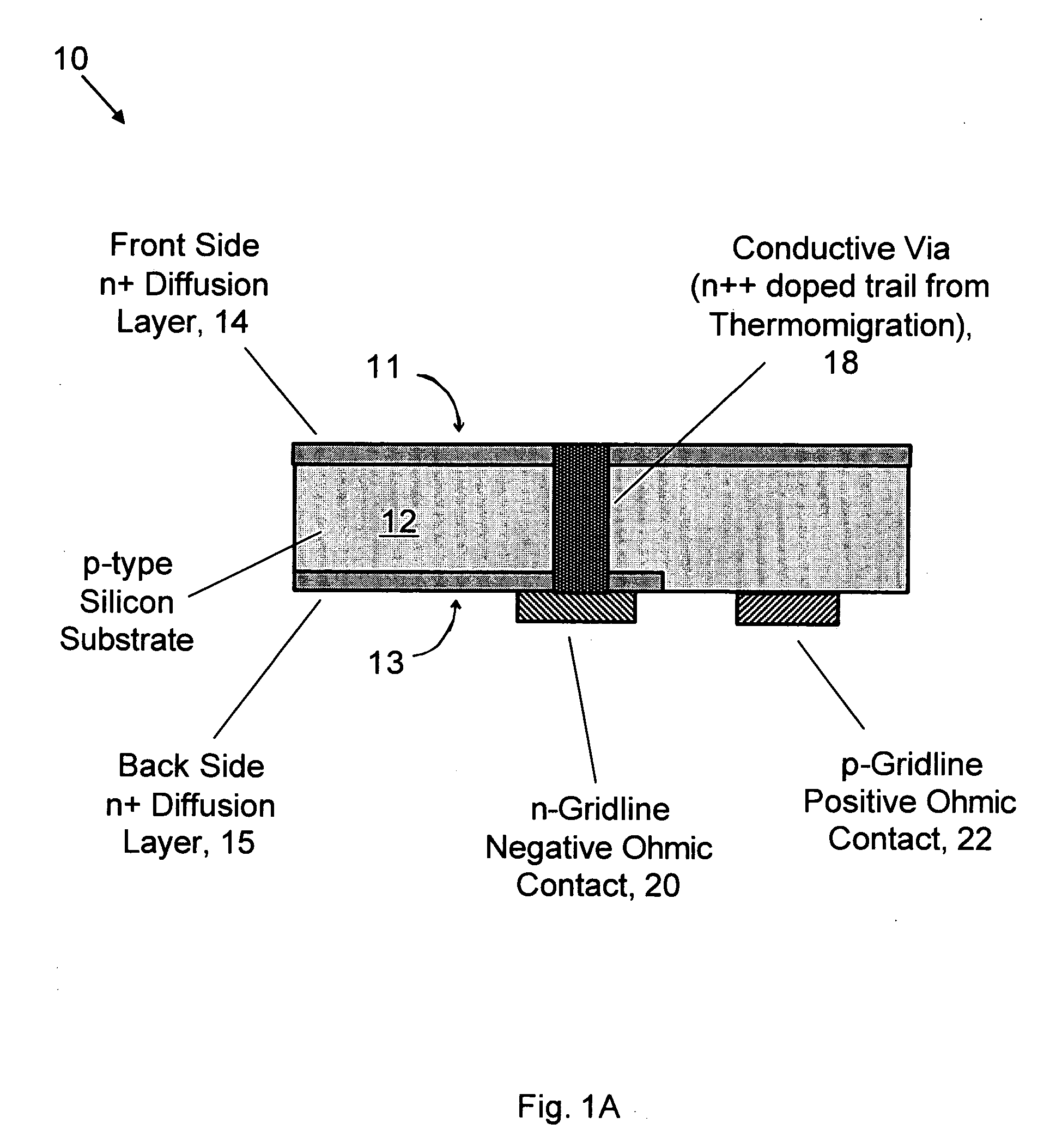

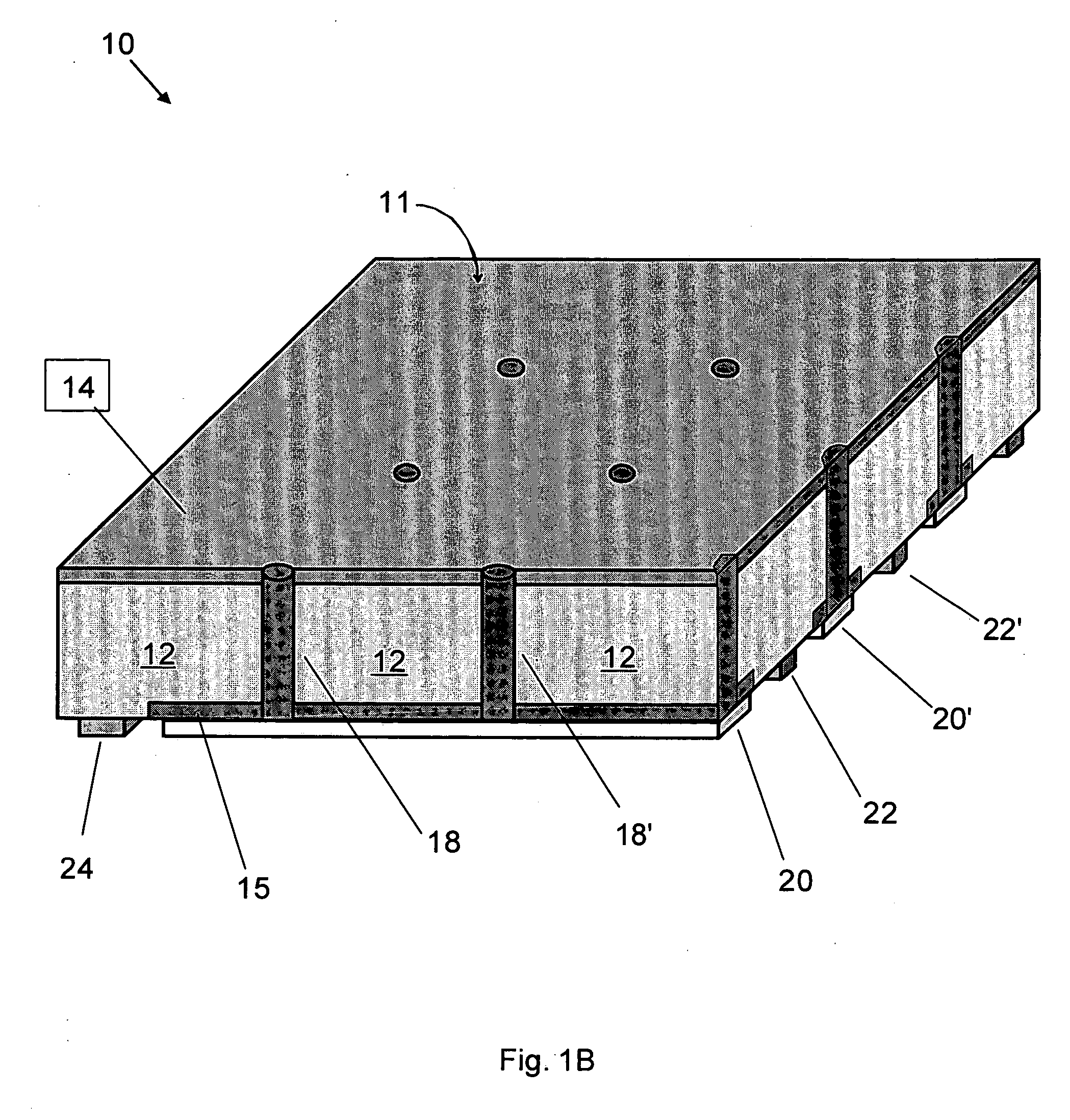

[0027] Note that in the drawings, the thicknesses of the various layers of insulating, semiconducting, and metallic materials, and other dimensions, such as the width of contact pads, are not drawn to scale, but rather are shown schematically for purposes of illustration and easy identification.

[0028] In the specification and claims, processes referred to as “thermomigration” include any gradient-driven migration process, including thermomigration and electromigration.

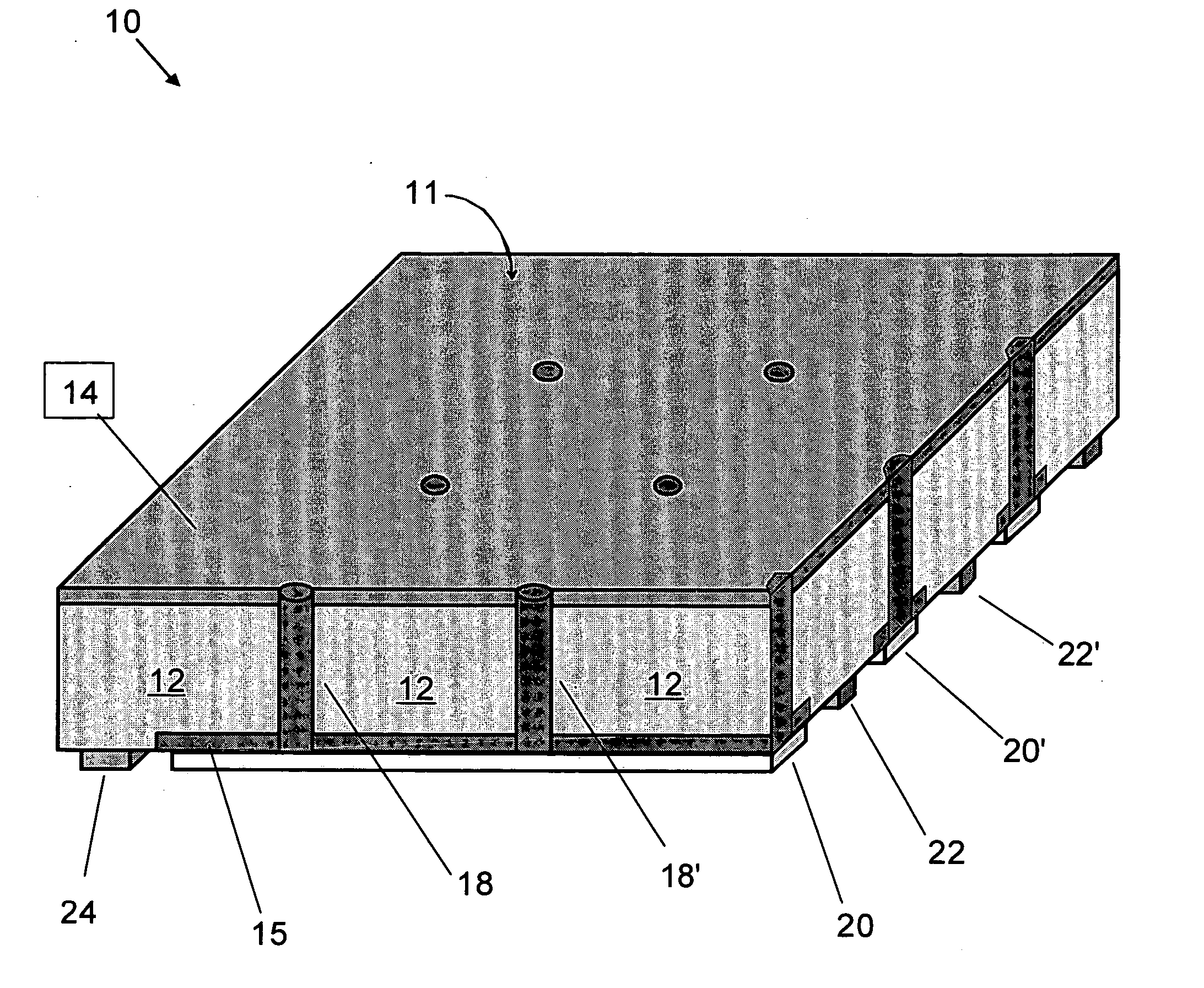

[0029]FIG. 1A shows a schematic cross-section side view of a first example of a back-contacted silicon solar cell, according to the present invention. Back-contacted solar cell 10 comprises a p-type bulk silicon substrate 12; a front side n+ diffusion emitter layer 14 located on the front side 11 of substrate 12; a back side n+ diffusion emitter layer 15 located on the back side 13 of substrate 12; a n-gridline negative ohmic contact 20 located on the back side 13 of substrate 12, contacting back side emitter layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com