Device and method for optical control under diffuse illumination and observation means of crockery items or any glazed ceramic products

a technology of optical control and diffuse illumination, which is applied in the direction of material analysis, geological measurements, instruments, etc., can solve the problems of not being able to provide inspection that is sufficiently high-performance and multi-purpose, not being able to meet the required detectivity, and no prior art system has been designed for pieces, etc., to achieve the effect of higher detectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

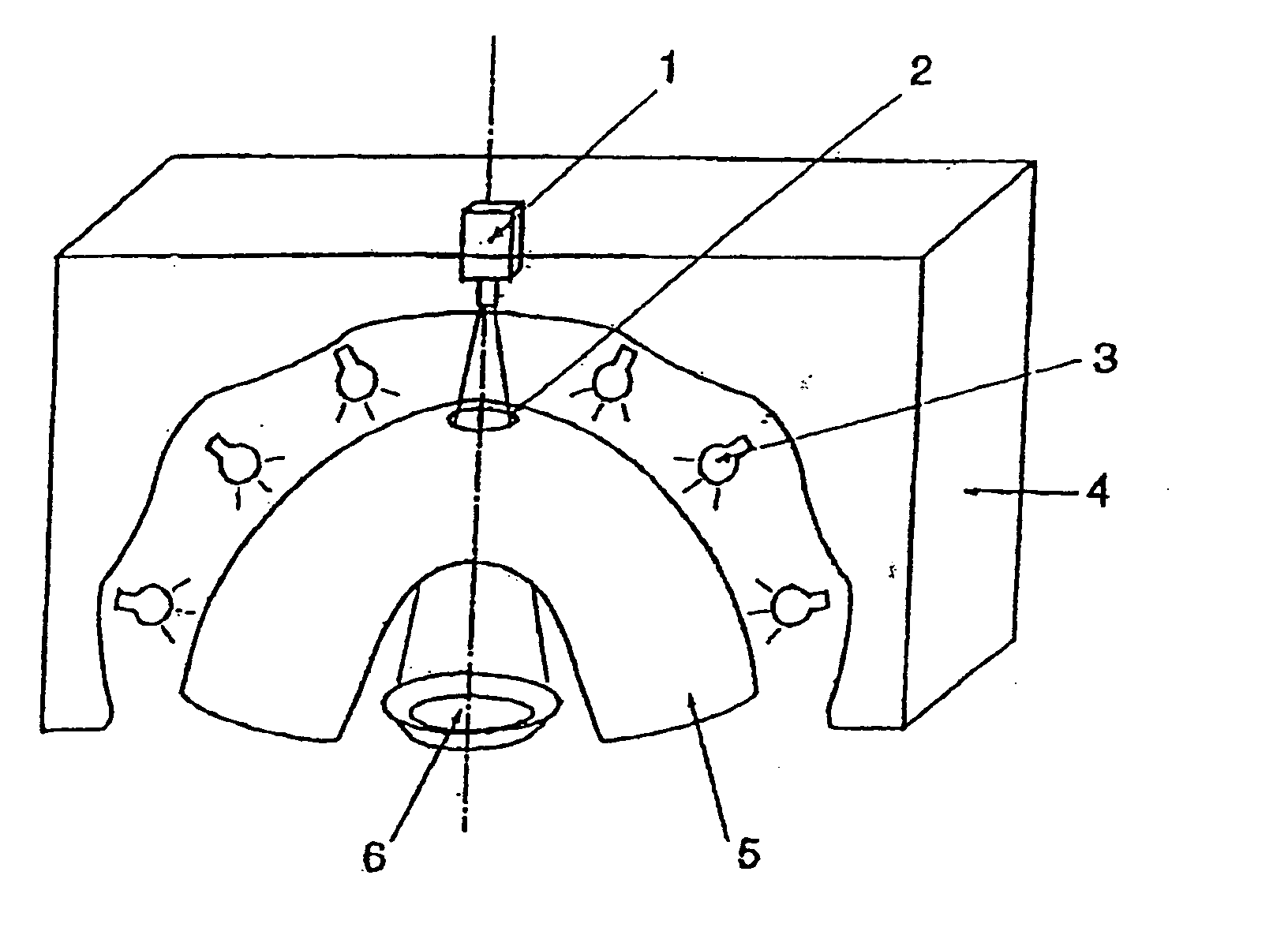

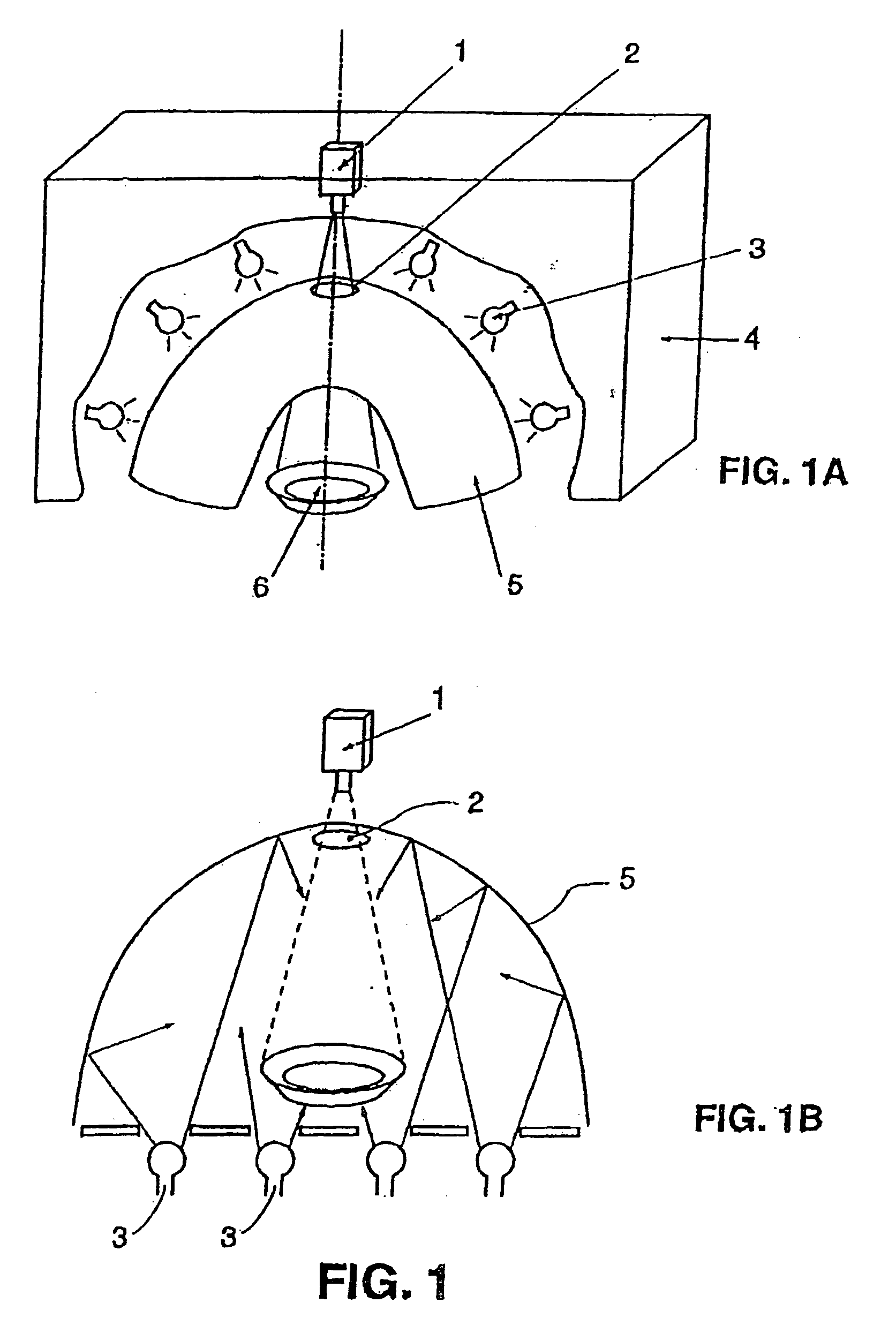

[0081] Accompanying FIG. 1A, which shows the overall diffuse lighting option, with, in this example, light sources uniformly distributed above a dome, shows that the pieces 6 pass under a translucent dome 5 that diffuses by transmission the light emitted by light sources 3 placed outside.

[0082] The diffused light is reflected by the piece, in particular towards the camera 1 through a suitable orifice 2 provided in the dome facing the camera. The resulting assembly is encased by a hood 4. The means for causing the pieces to advance under the dome are not shown. Only the inlet orifice is shown (an outlet orifice naturally exists in the direction of advance of the pieces).

[0083] Accompanying FIG. 1B shows the same configuration as FIG. 1A except that the light sources are placed under the dome and that the light is diffused by a, white opaque dome, by being reflected towards the piece.

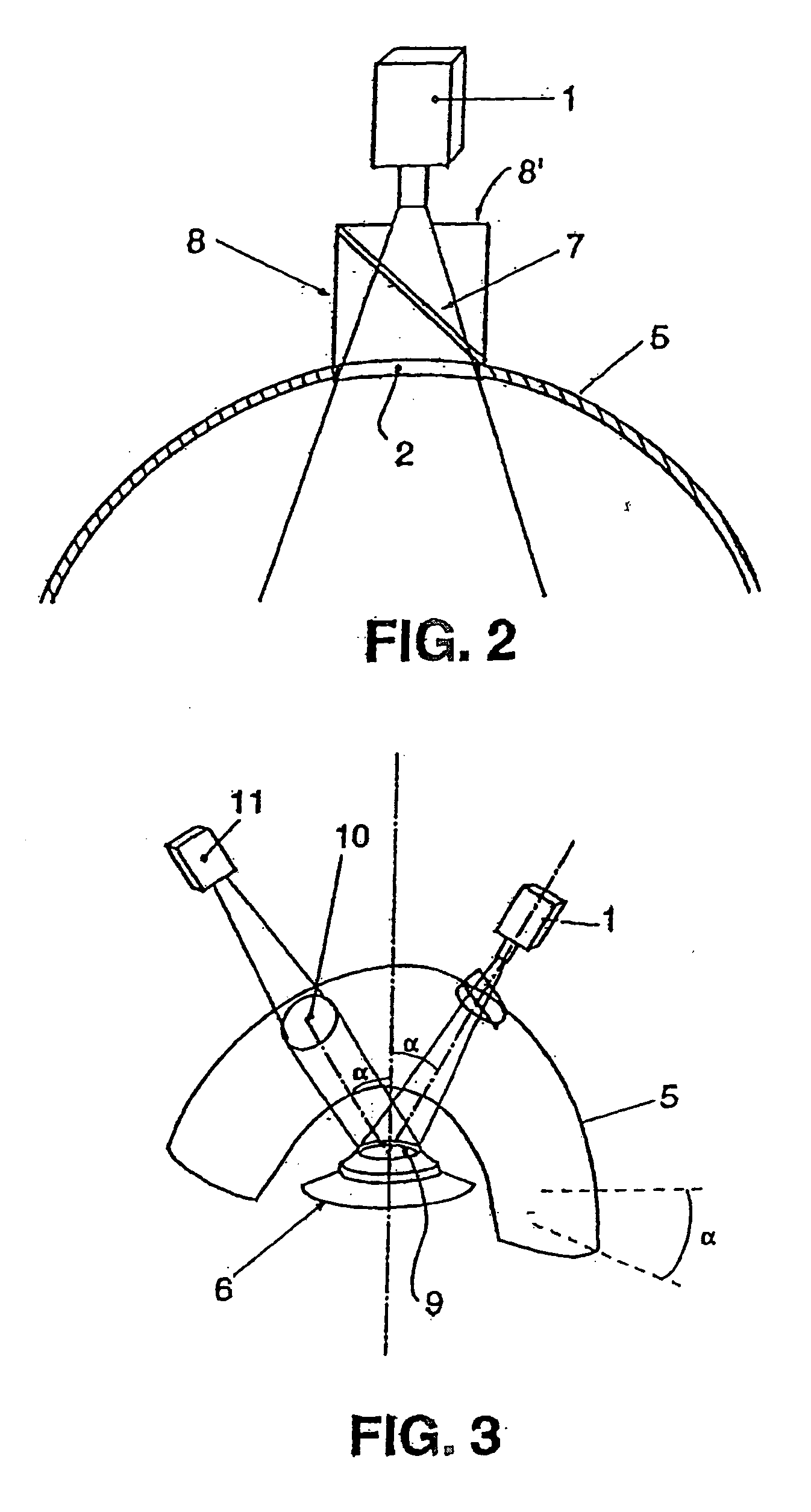

[0084] In FIG. 2, the apparatus is as shown in FIG. 1, except that a semi-reflective strip 7 is ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| frequencies | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com