Light-emitting apparatus and method for forming the same

a technology of light-emitting apparatus and light-emitting device, which is applied in the direction of discharge tube/lamp details, luminescnet screen, discharge tube/lamp details, etc., can solve the problems of low extraction efficiency of light-emitting apparatus, uneven surface of light-emitting device, and specular reflection of external light, so as to prevent specular reflection and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Several embodiments of the present invention will now be described with reference to the drawings. Same reference numerals are similar or the same in the drawings. A first organic EL apparatus will now be described.

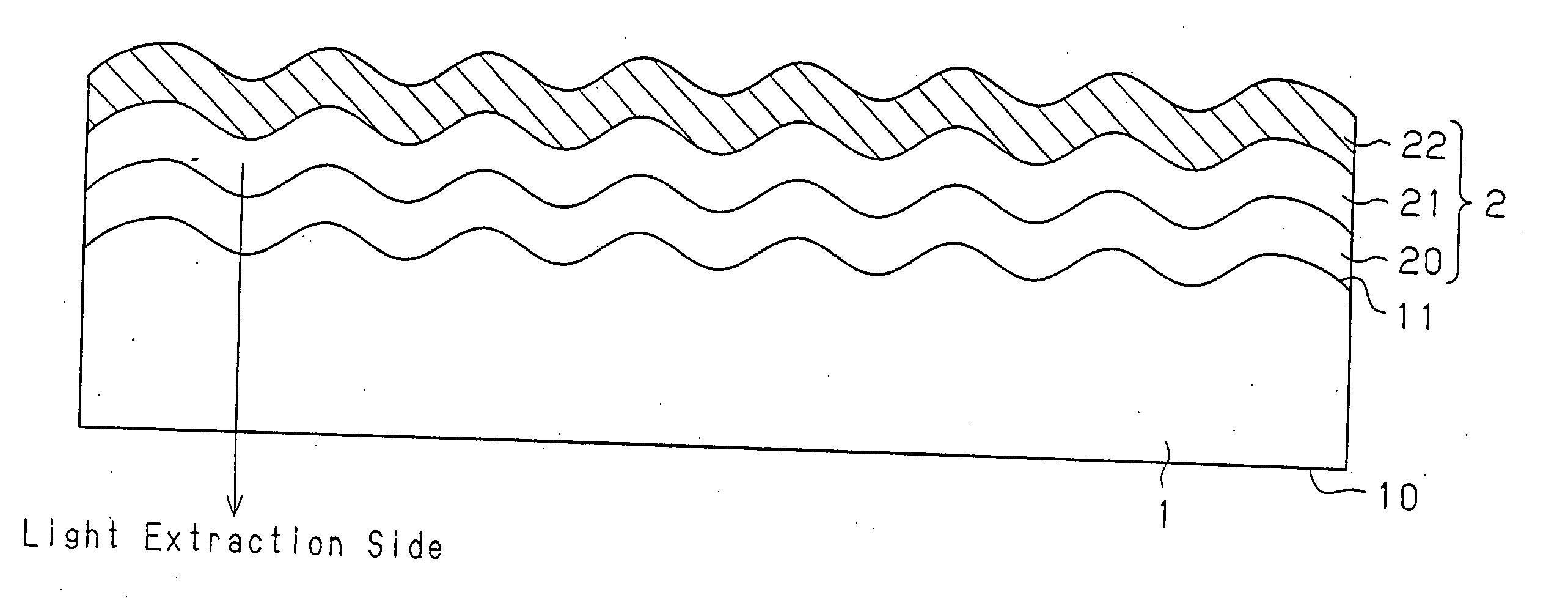

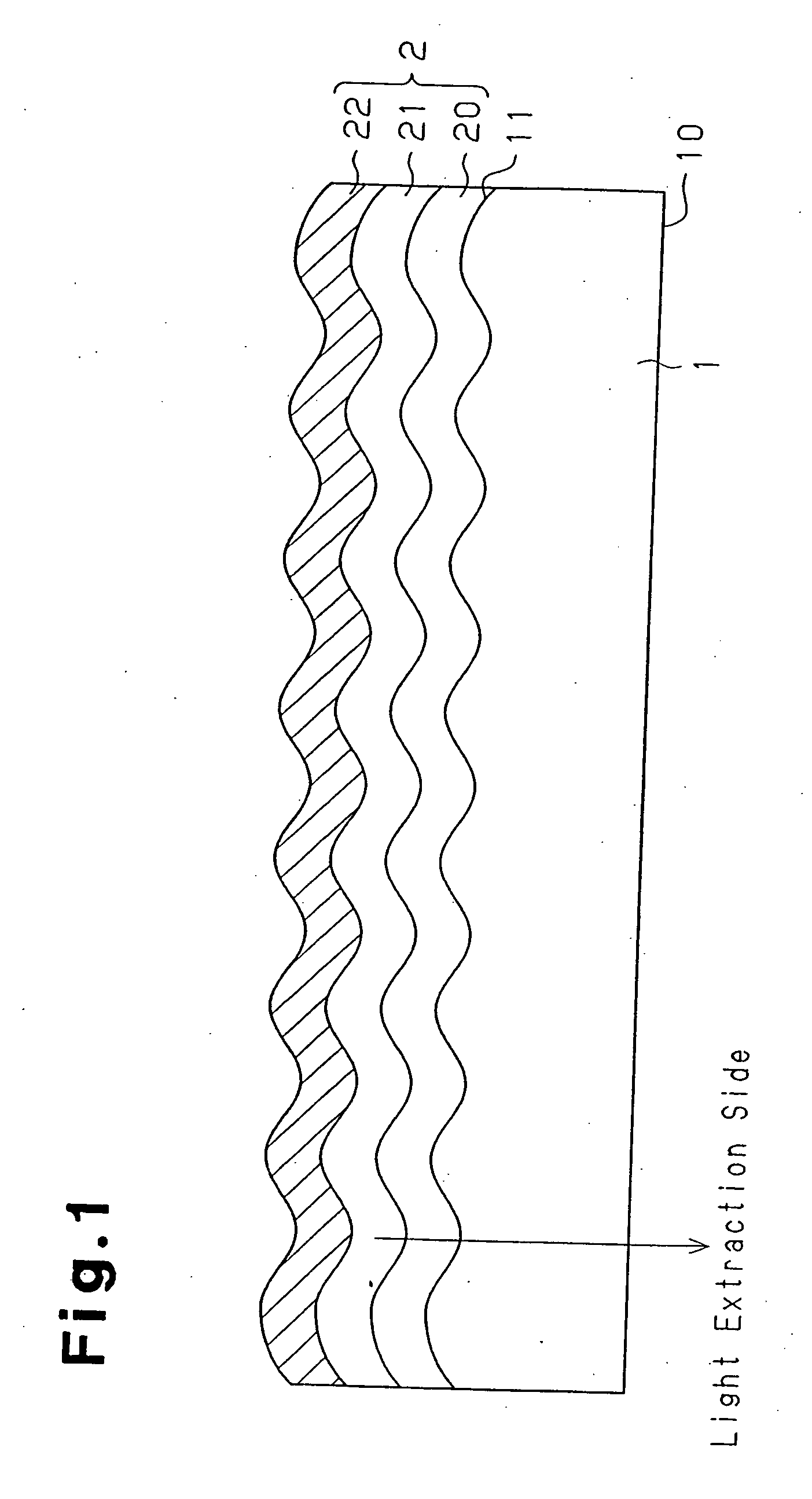

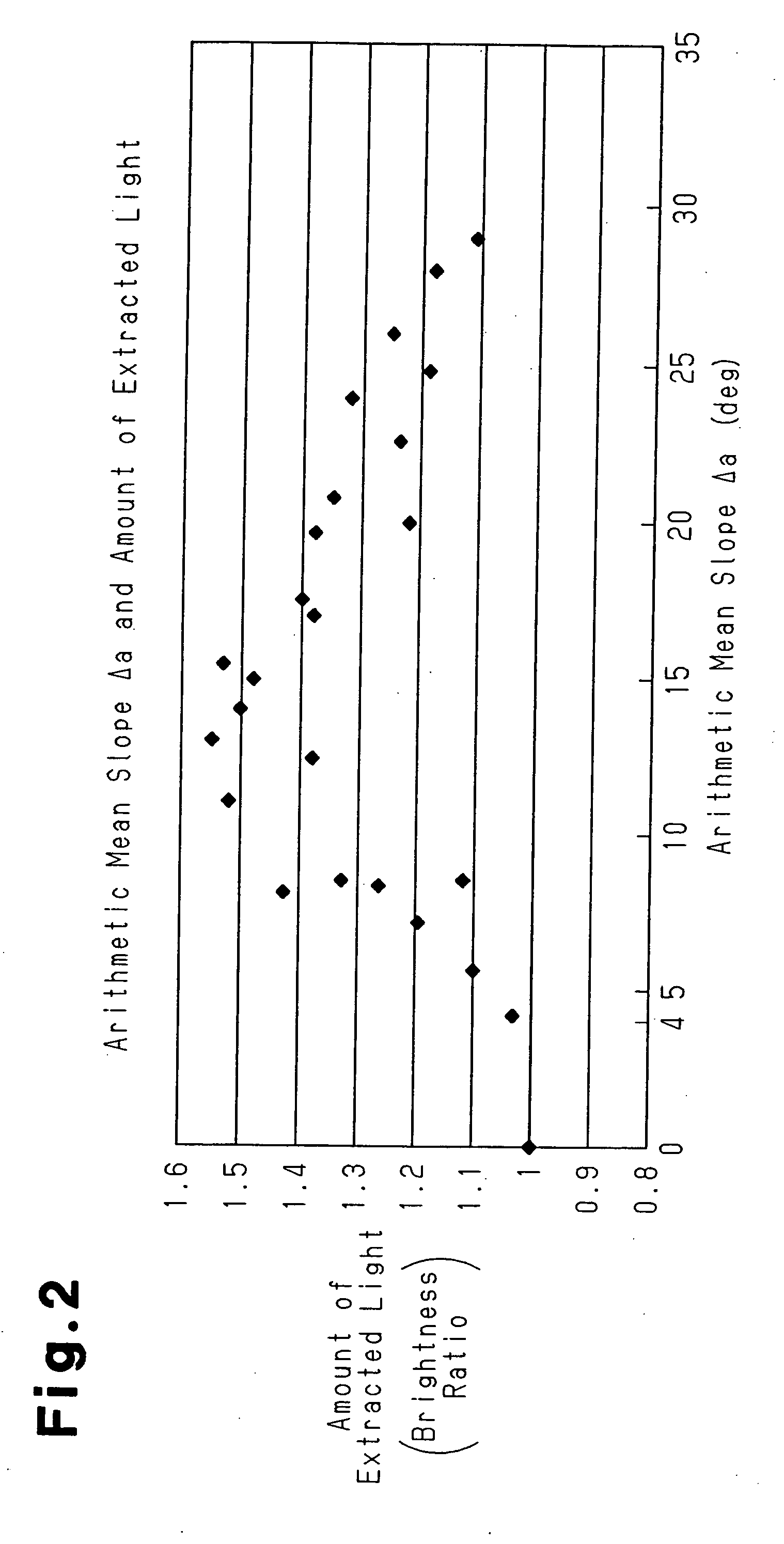

[0056] As shown in FIG. 1, the first organic EL apparatus is of a bottom emission type that includes a transparent substrate 1 and an organic EL device 2. Asperities are formed on one face of the transparent substrate 1 (a incident surface 11). In other words, the incident surface 11 is an uneven surface. The organic EL device 2 is formed on the incident surface 11.

1>

[0057] The substrate 1 is a substantially plate-shaped transparent member that supports the organic EL device 2. The substrate 1 has the incident surface 11 on which the organic EL device 2 is formed, and a light exit surface 10 that is located opposite from the incident surface 11. The substrate 1 receives light from the organic EL device 2 through the incident surface 11, and emits the received lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com