Energy saving environmental chamber temperature control system

a temperature control system and environmental chamber technology, applied in the field of controlled temperature chambers, can solve the problems of increased power consumption and no manufacturer of environmental or cold storage rooms with a leed rating, and achieve the effect of reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

1. Refrigeration system

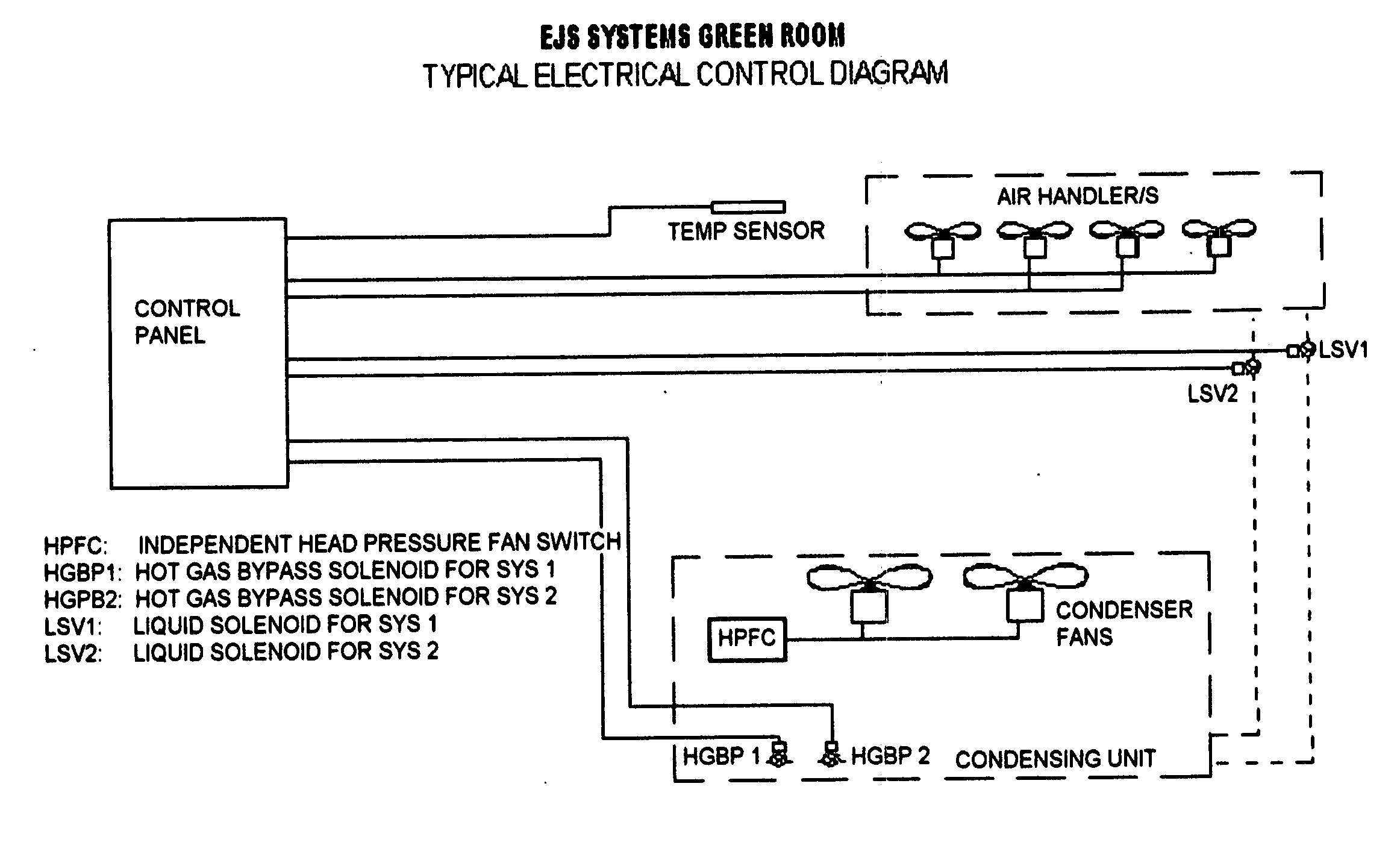

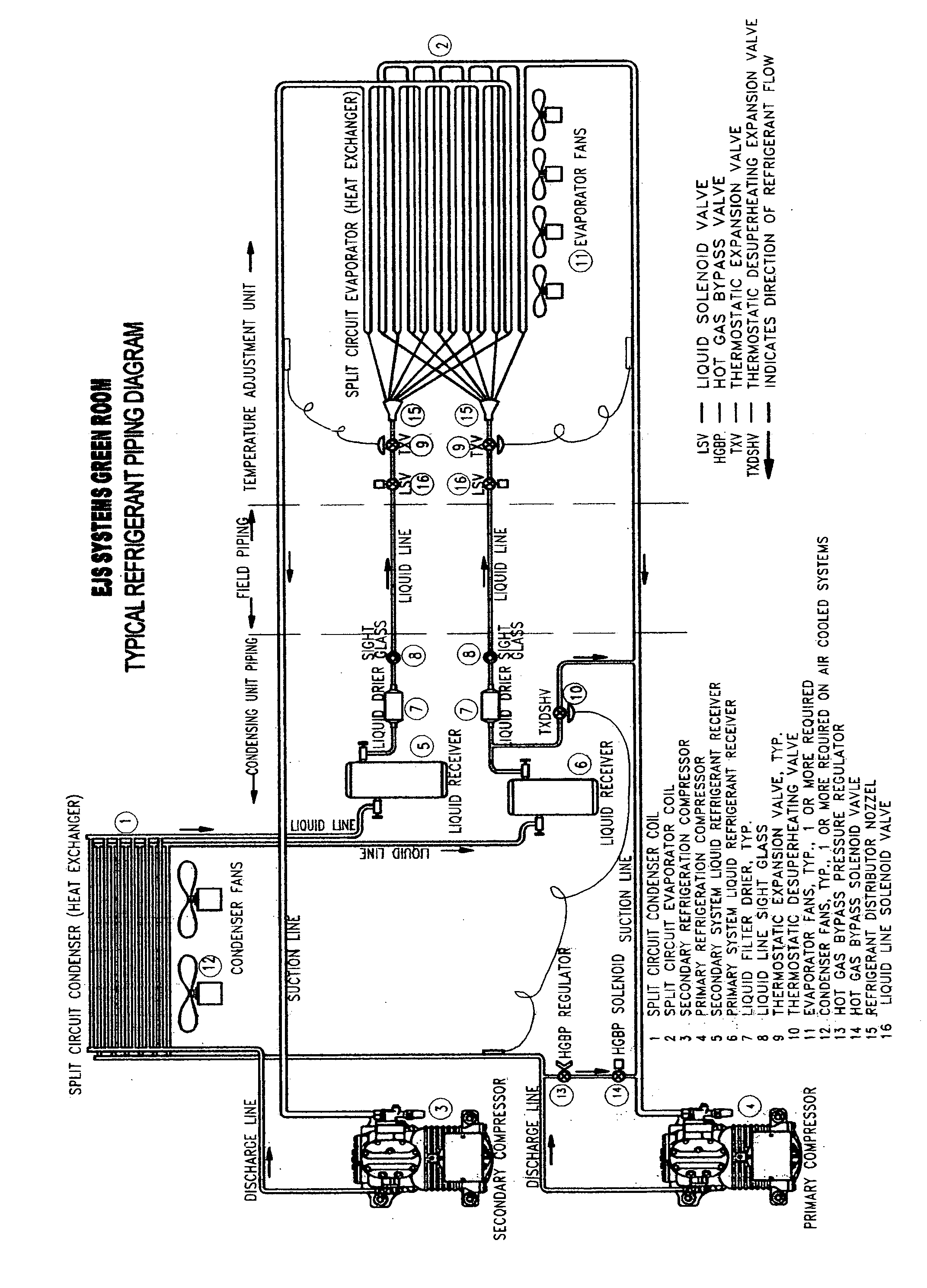

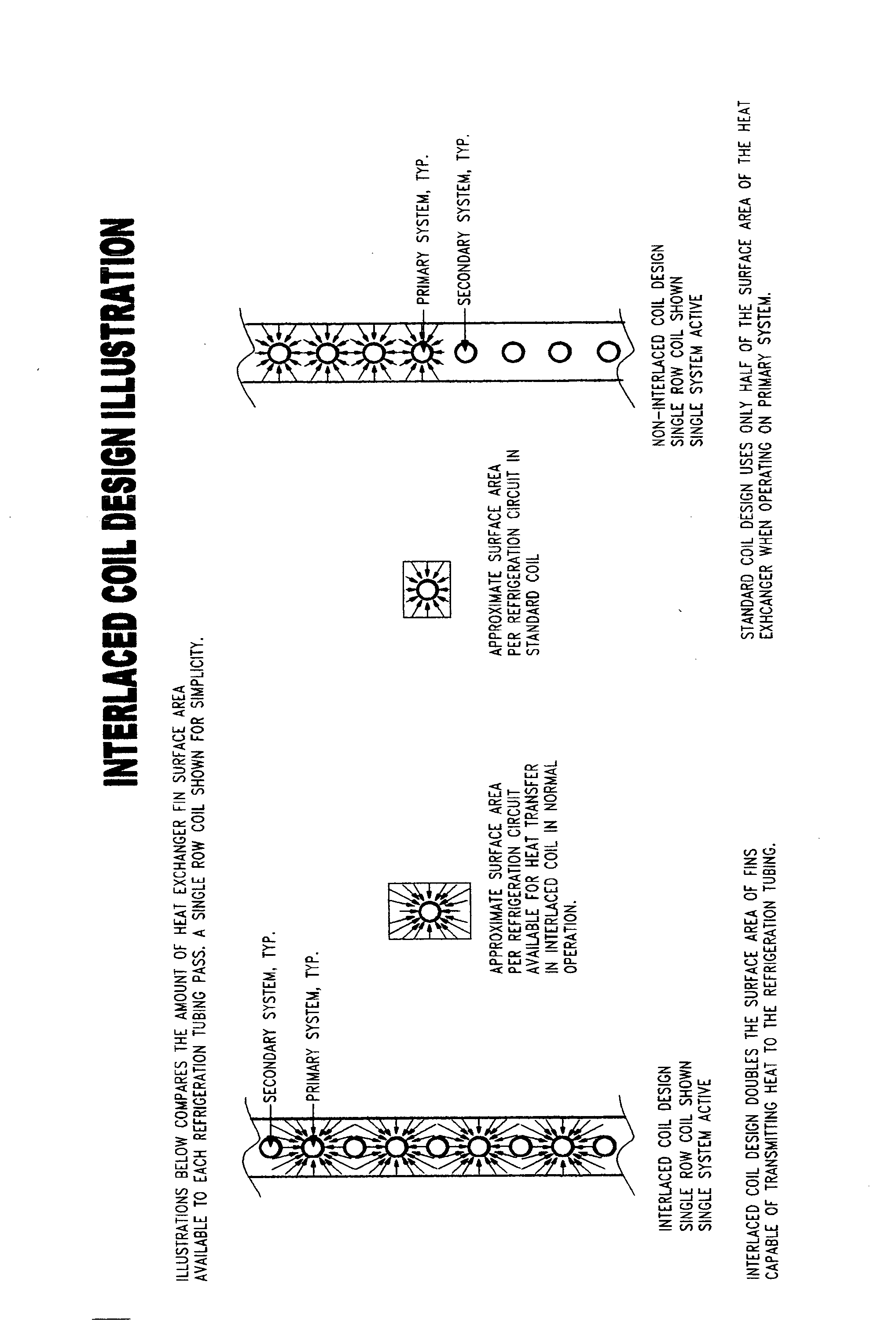

[0022] a) The refrigeration system on an environmental or cold storage chamber often experiences two extremes of operation. One is that the temperature is good and there is little or no traffic or heat being generated within the chamber. The other is just the opposite, the temperature is slightly high, people or materials are being brought in or out of the chamber and the system is running at full capacity to maintain temperature. [0023] b) A large system designed to take care of the most extreme loads is substantially oversized when compared to what is needed during periods of inactivity. It is those times where the standard system is most ineffcient. [0024] c) The Green Room System consists primarily of two components. One is the mechanical equipment, consisting of the compressors, receivers, evaporator fans, condenser fans, refrigerant controls and heat exchangers. The mechanical system is composed primarily of two components, the condensing unit and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com