Cylinder head structure of engine

a technology of cylinder head and engine, which is applied in the direction of machines/engines, cylinders, mechanical equipment, etc., can solve the problems of not providing more appropriate cooling function for respective portions, reducing the temperature around the ignition plug, and unable to properly cool down, so as to improve the cooling function of the exhaust-side portion efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

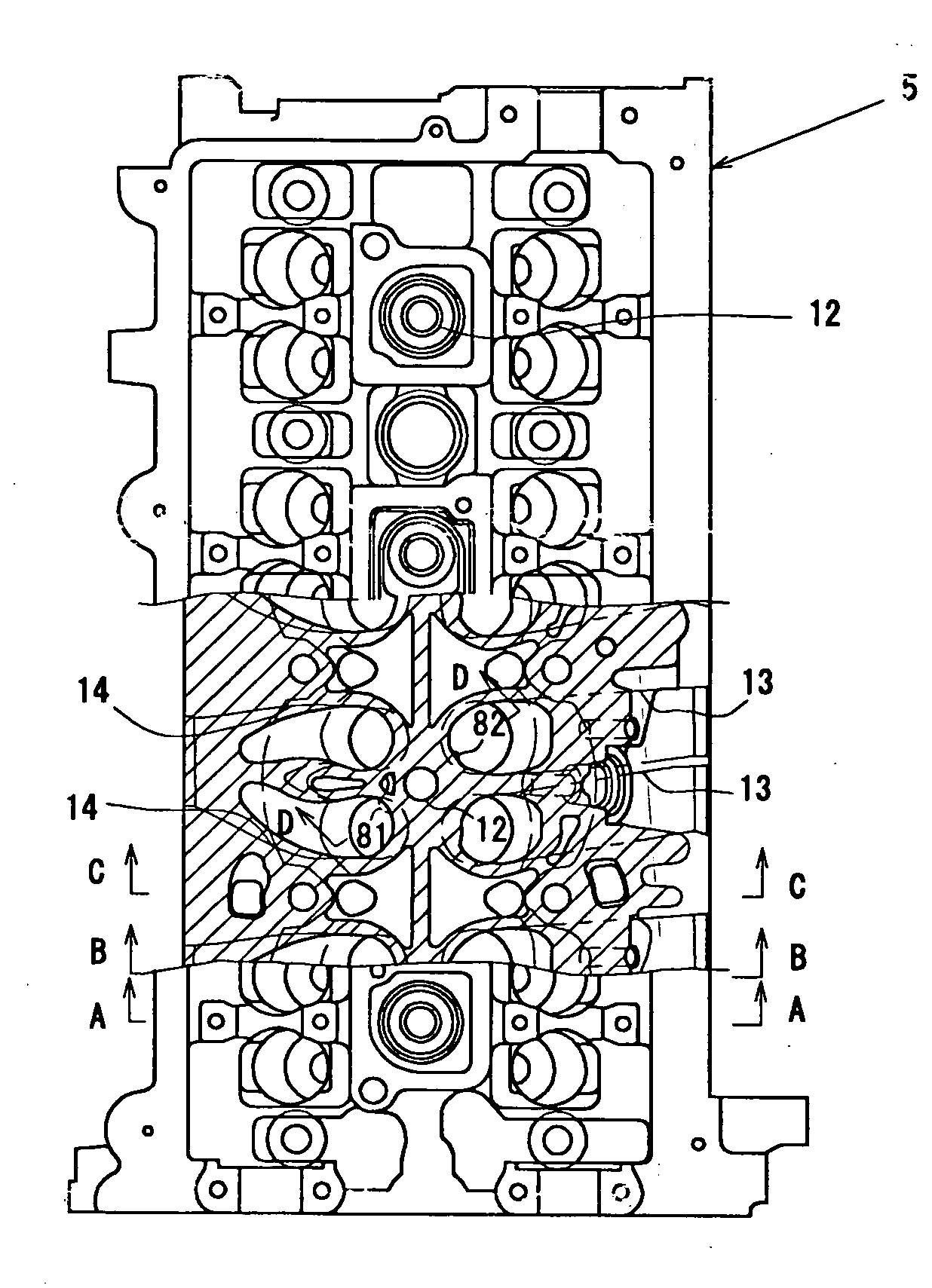

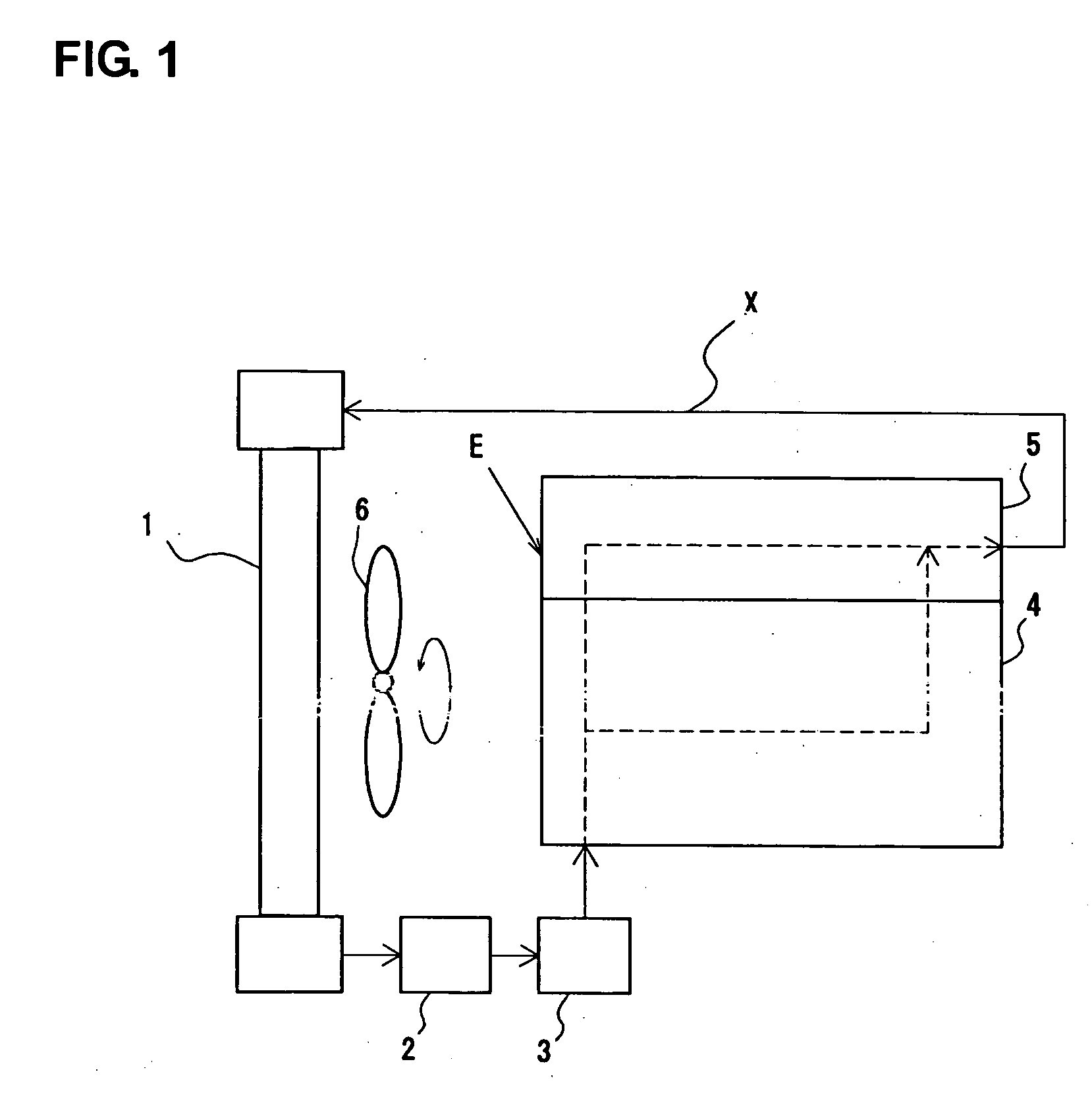

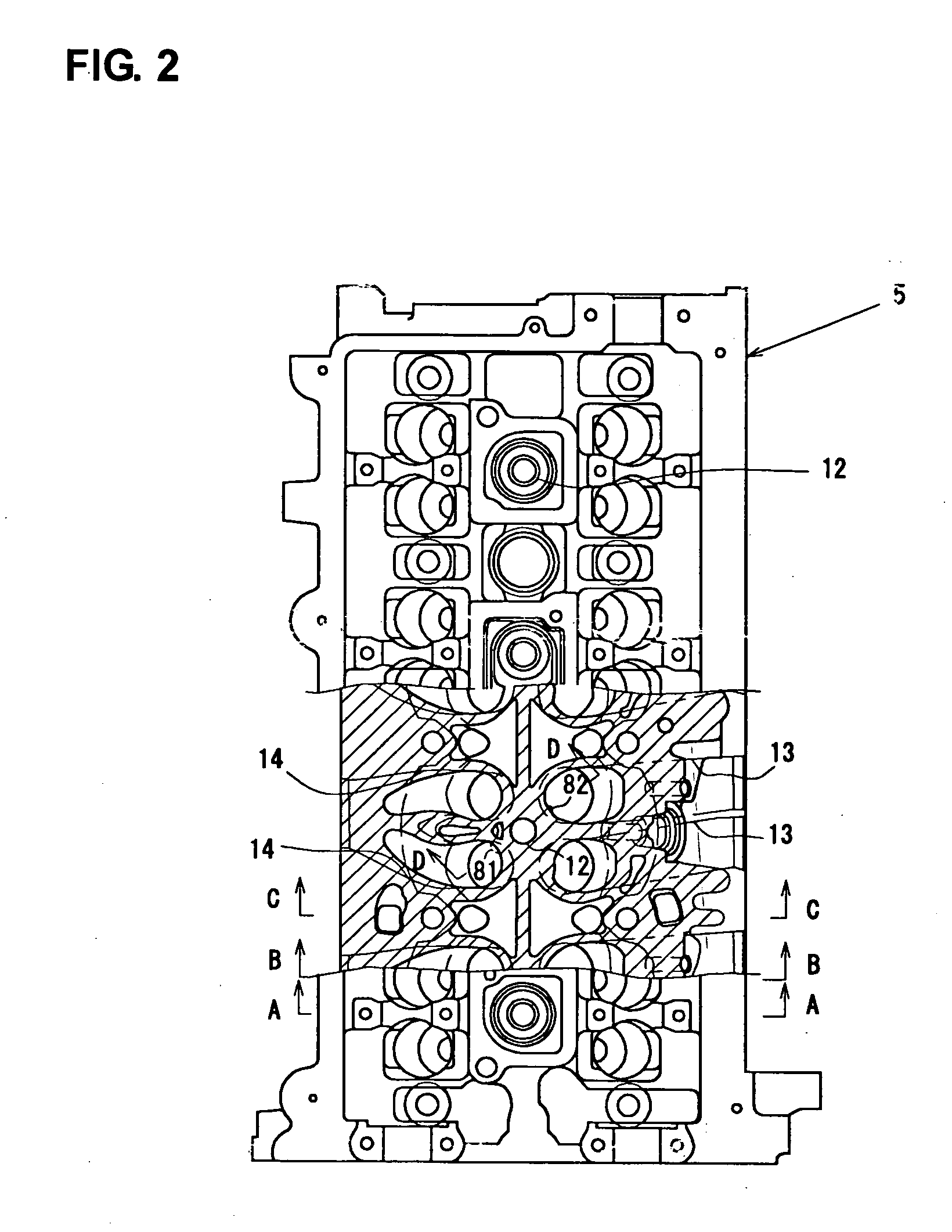

[0046] Hereinafter, an embodiment of the present invention will be described referring to the accompanied drawings. FIG. 1 is a schematic diagram of a coolant path X of an engine E with a cylinder head according to the present invention.

[0047] The coolant path X of the engine E comprises a coolant circulation path that includes a radiator 1 to cool heated coolant, a thermostat 2 to control the flow volume of the coolant, a water pump 3 to supply the coolant in the path, a cylinder block 4 to be cooled by the coolant, and a cylinder head 5 to be cooled by the coolant likewise. The engine E is cooled by the coolant that is circulated in this path. Herein, a cooling fan 6 is provided to cool the radiator 1.

[0048] The flow volume of the coolant in the coolant path X is adjusted to a specified volume by the water pump 3 and others. Thus, the cooling function of the engine E depends on how to control distribution of the coolant in the path.

[0049] According to the present embodiment, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com