Screw-on closure for a recipient

a screw-on cap and recipient technology, applied in the direction of closure lids, closure stoppers, caps, etc., can solve the problems of deformation of the outer appearance of the screw-on cap, unreliable operation of current tamper-resistant systems, and insufficient assurance, so as to simplify the screw-on cap manufacturing and filling line application process, the effect of eliminating the tamper-resistant band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

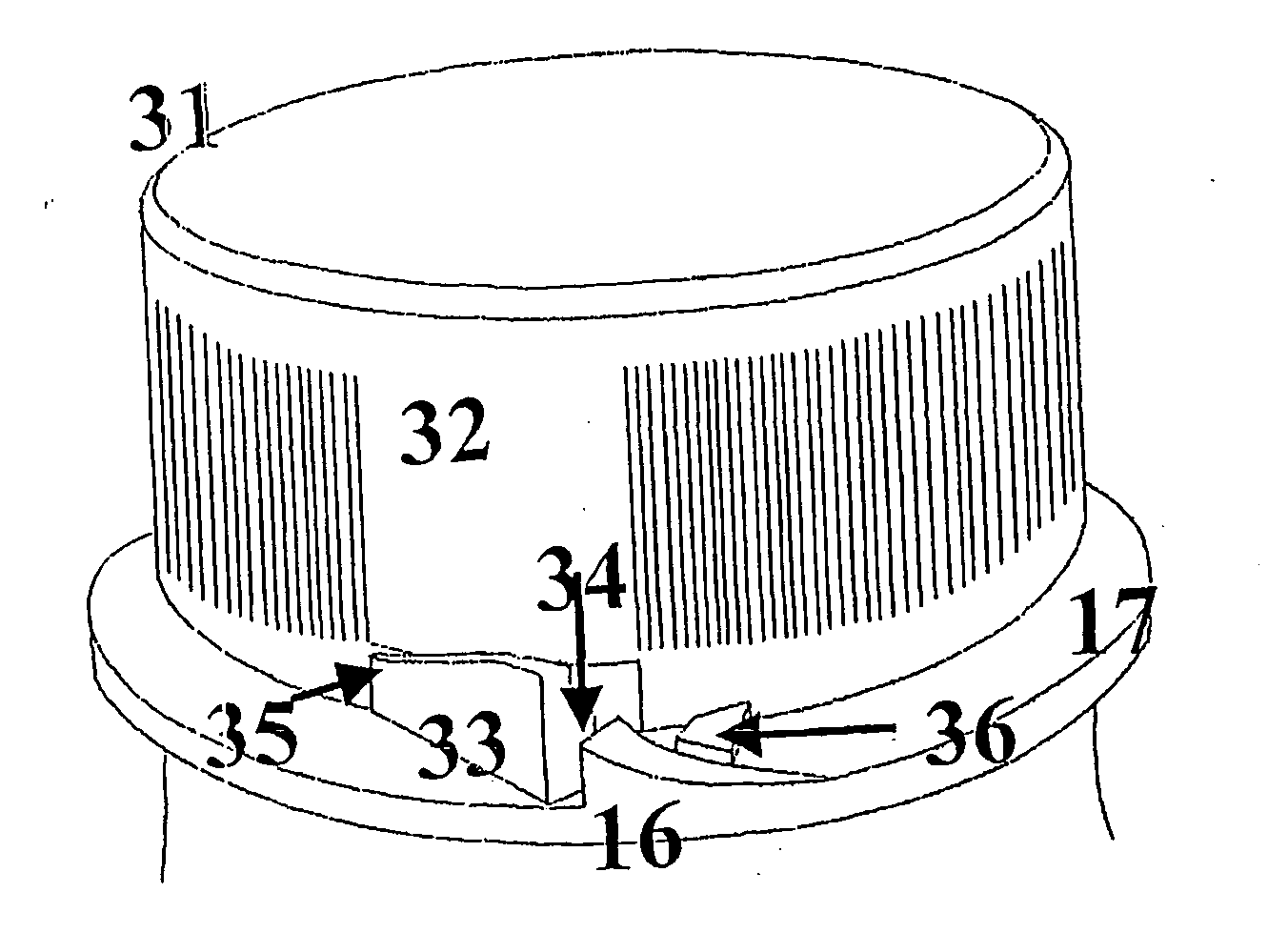

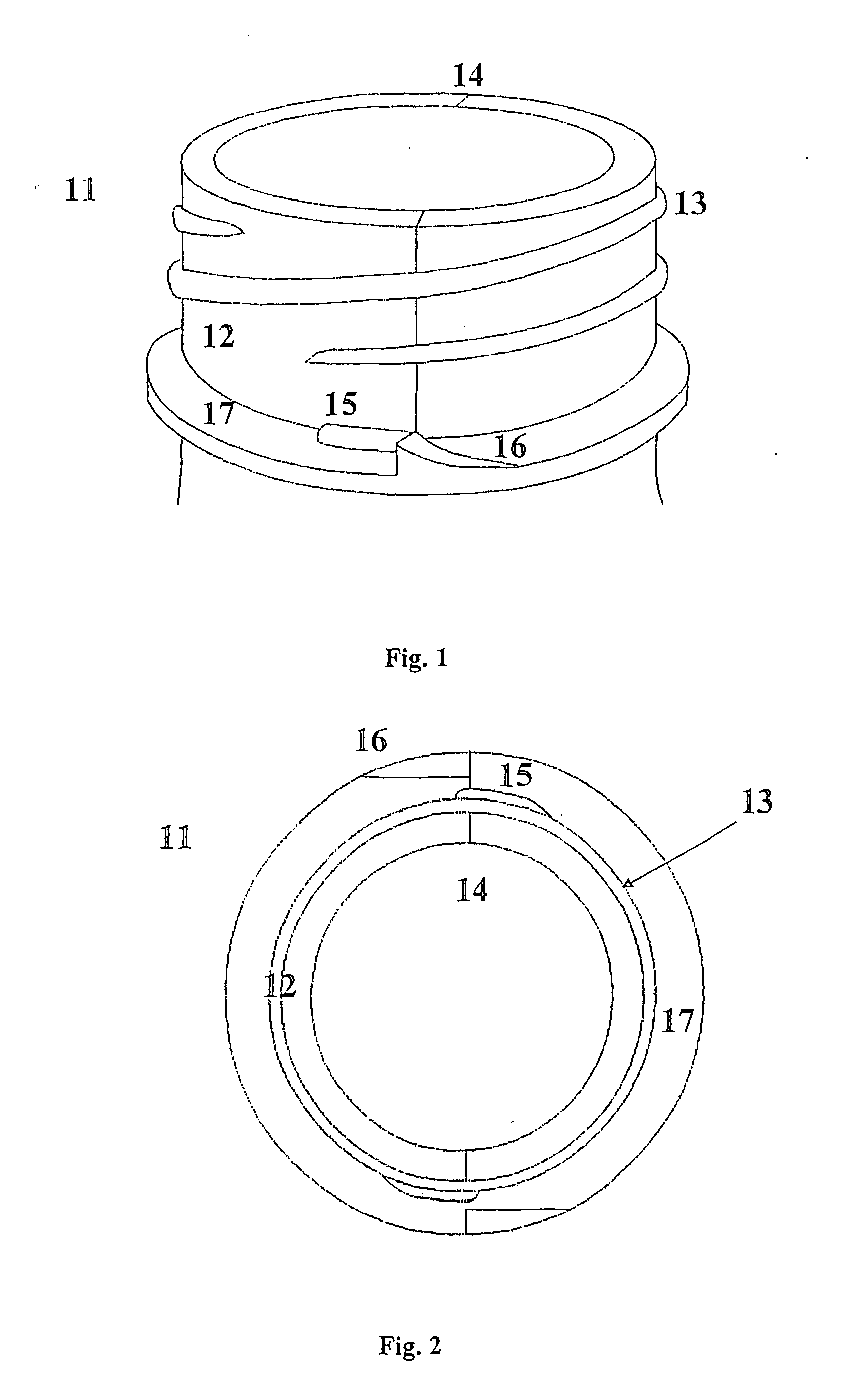

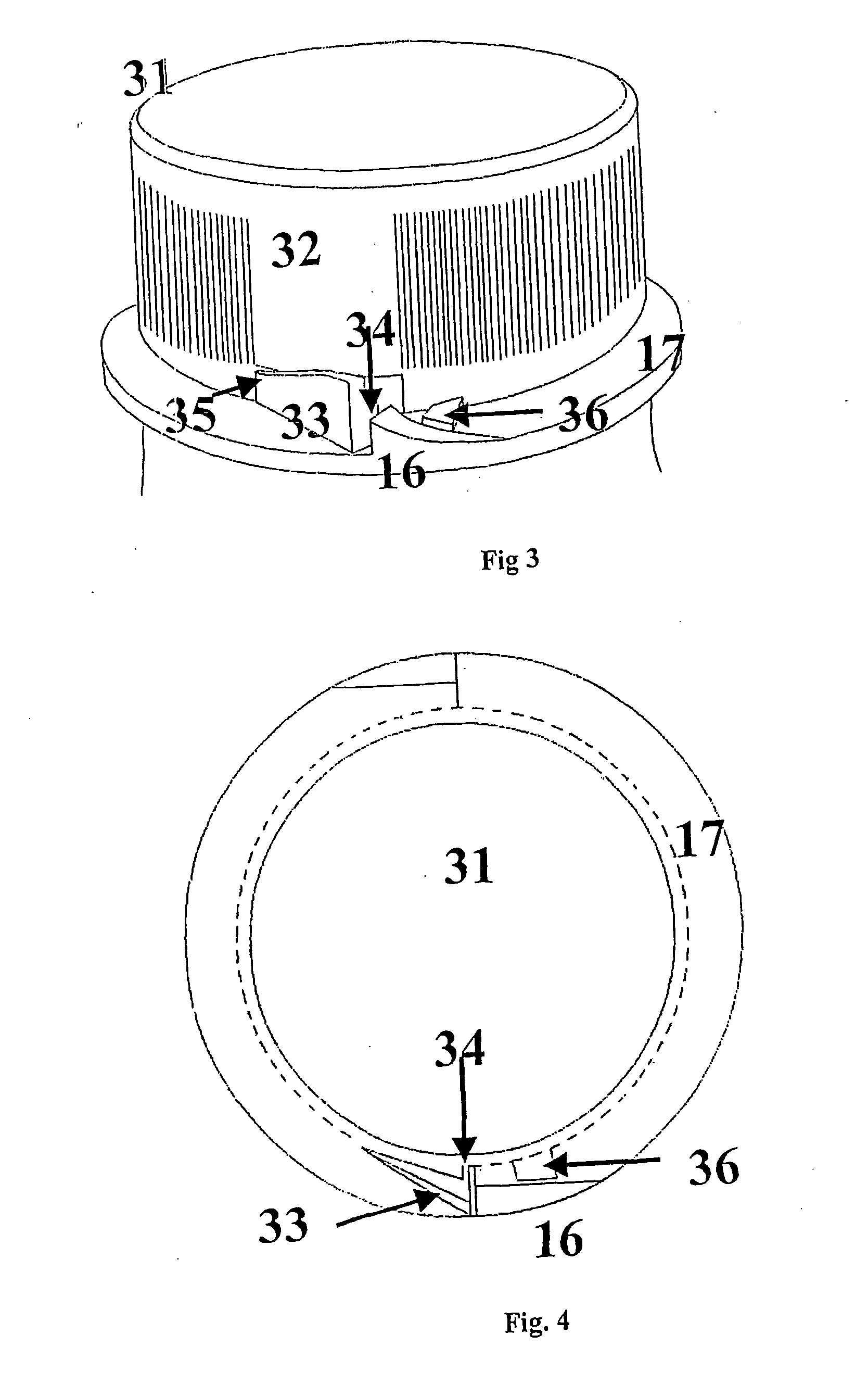

[0029]FIG. 1 represents a retention or locking device 15, 16 located under the outer screw thread or threads 13 located on the neck 12 of a container or recipient 11. The recipient 11 is preferably made of a plastic material so that the material can be injected in an injection mold. The recipient 11 is suitable for storing a substance such as a liquid, a carbonated beverage or the like.

[0030] The retention device comprises a first projection 15 and a second projection 16 or ribs close to the contact edge 14 of each one of the two parts or halves constituting the container 11.

[0031] As can be seen in FIG. 2, each half of the container includes a first rib 15 and a second rib 16, each one of them located at one of the contact edges corresponding to one half of the container 11. For example the first rib 15 is in contact with the neck 12, that is, in contact with the outer face of the cylinder of the neck of the container 11 and on a horizontal base ring 17 which is located under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com